Mating integrity is key to car connection technology

High demands are placed on each plug connection in automotive systems, which means secure and robust connections are crucial to prevent failure during operation. Connector systems must provide high vibration resistance, temperature resistance and easy handling.

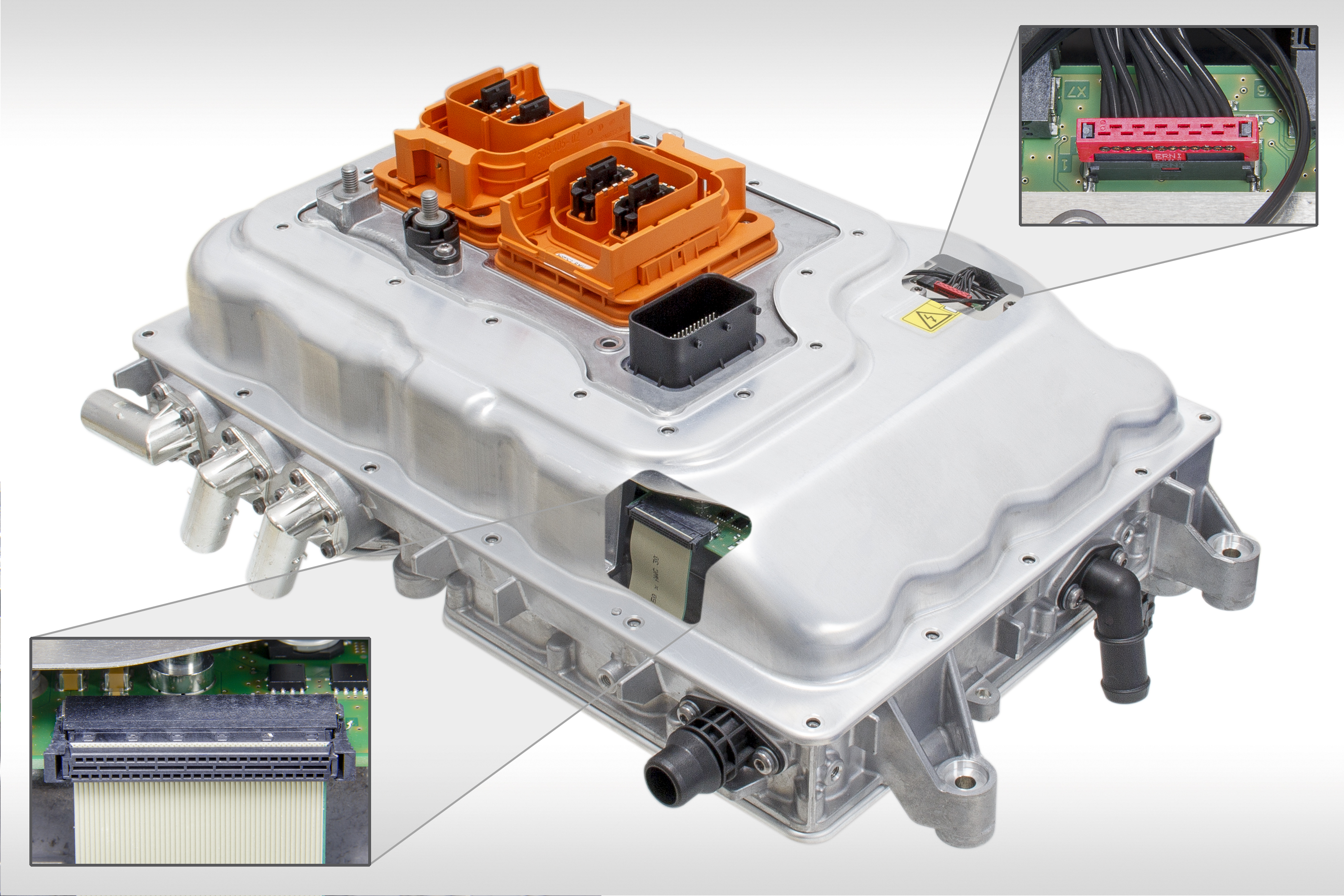

Battery management systems and the corresponding power electronics (inverters) play a key role in electromobility. When it comes to ensuring board power, controlling power flow and transmitting high currents, connectors are required that meet specifications in terms of miniaturisation, ease of processing, current carrying capacity, mating security and reliability.

Batteries and LEDs

The battery management system (BMS) ensures safe charging/discharging of the battery and monitors the battery cells. It is not usually installed directly in the high-voltage battery, but is connected via decoupled bus systems (e.g. the controlled area network or CAN). Fundamentally, the contact resistance at the charge input must be kept as low as possible. This typically requires connectors that have the lowest possible contact resistance that remain largely constant even with rising temperatures. This can be achieved by a suitable contact design.

Another growth driver for automotive lighting systems is the increasing market penetration of LED technology, for headlight systems in particular. Corresponding connector systems tested according to automotive standards must guarantee that the assemblies function perfectly in all weather and road conditions. Robust interlocking and surface mount solder joints resist even severe vibrations and shocks. Even high temperatures, which occur in the tight spaces in headlight systems, should not pose a problem. Flexible, miniaturised cable-to-board solutions and a high degree of mating security are the key criteria here.

Figure 1: Connectors such as SMC and MiniBridge are installed in inverters or battery management systems of EVs.

Confined spaces

MiniBridge connectors are particularly well-suited to applications such as LED headlight systems, IR distance sensors, head-up displays or switch elements. LED systems are often wired or modularly connectable with printed circuit boards. With appropriately assembled MiniBridge cable connectors, which can accommodate both ribbon cables and single wires, a particularly simple, flexible and cost-effective installation is possible. For such compact lighting tasks, the MiniBridge connectors are also available with „white" insulation. Connectors with non-coloured insulation prevent the shadowing effects in lighting applications, e.g LED strips with transparent diffusing lens. This ensures uniform light distribution.

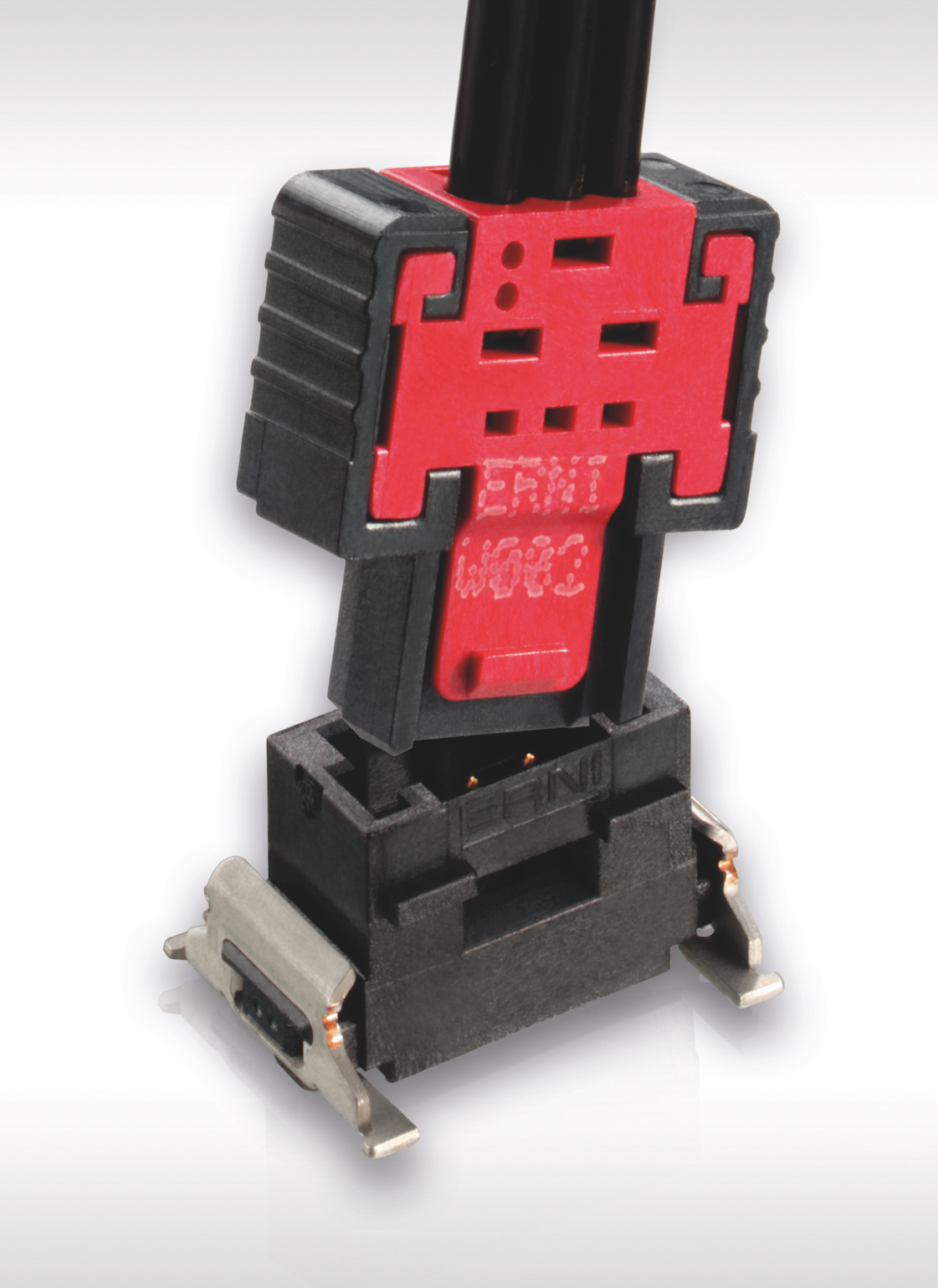

The automotive industry in particular places high demands on the process reliability of mating connections. The design must ensure that the male connector is not damaged, especially if the male and female connectors are not mated at the correct angle, i.e. skewed. The MiniBridge connectors in the Koshiri design ensure that this requirement is met during the mating process.

Figure 2: MiniBridge cable connectors include the Koshiri variant.

Figure 2: MiniBridge cable connectors include the Koshiri variant.

Tongues on the female connector and grooves on the male connector allow the pre-alignment of the connector housings, thus ensuring a precise mating process. The design is also known as “scoop proof” - the pin contacts are recessed sufficiently so they cannot be damaged if the mating connector shell is scooped into it during the mating process. More specifically, the MiniBridge Koshiri design prevents pins from being bent and contacts from being shorted during mating.

The key features of the cable connector system are a compact format combined with high performance and reliability. With dimensions of only 10 x 10 x 3.0mm for the four-pin version, a very high current carrying capacity (when using appropriate cables) is achieved over the -55 to +125°C temperature range due to a special contact material. Straight and angled male connectors and female connectors with an angled and straight (90 and 180°) cable outlet can be used to address a wide range of applications.

MiniBridge connectors are available with two, three, four, six, eight, 10 and 12 pins. The male connectors have surface mount technology (SMT) terminals for economical processing, while the female connectors use insulation displacement contact (IDC) technology. The female connectors are also available with various interlocking techniques for normal vibration/shock loads (black design) and for high vibration/shock loads (red design). With the more robust version (in red), the interlocking can only be released with a tool (screwdriver).

Safety locks

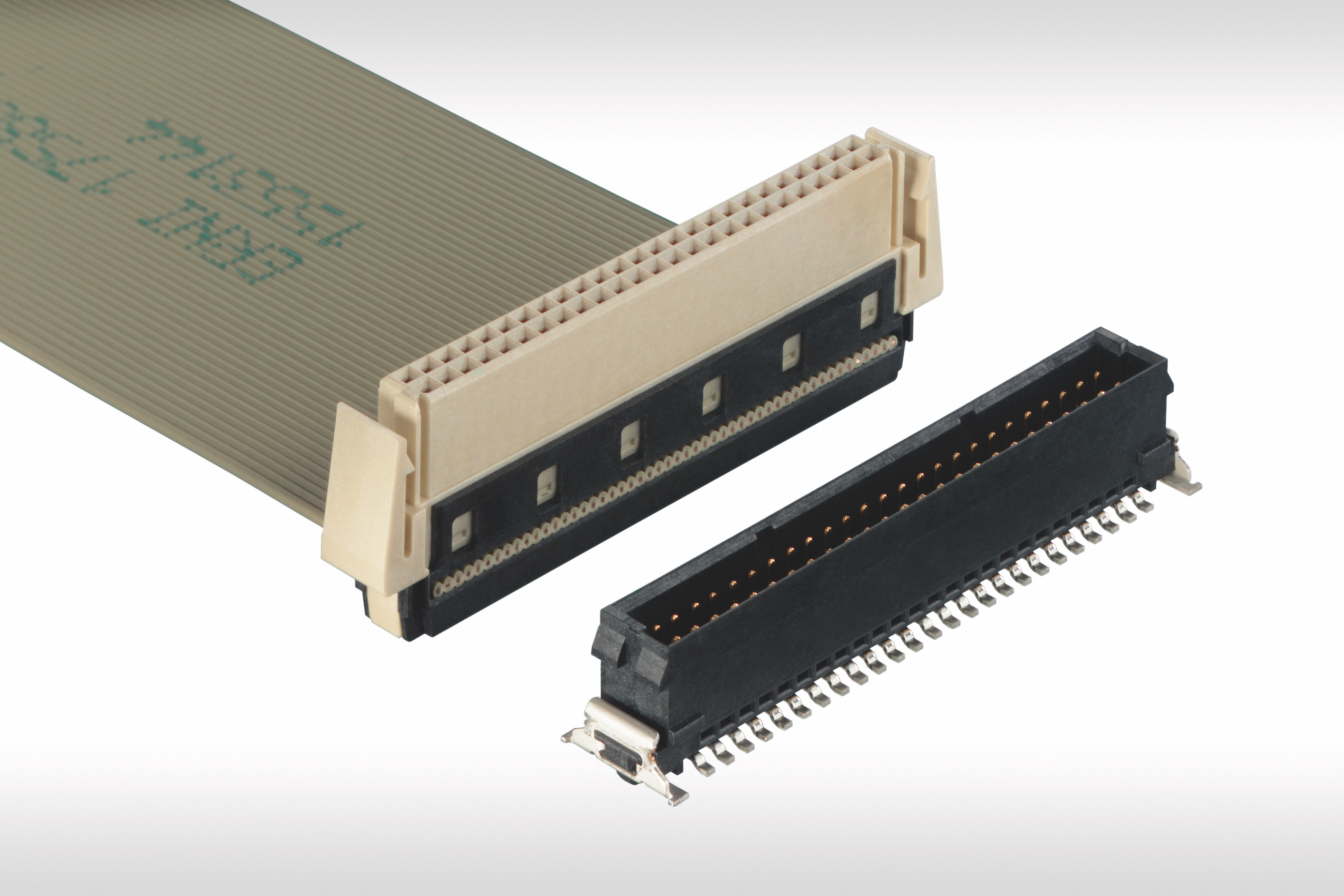

The SMC family has a 1.27mm pitch, making it suitable for demanding, often spatially confined applications in the automotive sector. A recent development is the SMC Secure Lock. This extends the SMC connector family to include versions with Secure Lock interlocking. A reliable electrical contact is provided when mated by the proven dual-beam female contact.

Figure 3: SMC Secure Lock is a wire-to-board connector designed for the automotive industry.

Figure 3: SMC Secure Lock is a wire-to-board connector designed for the automotive industry.

To ensure the secure, mechanical connection of two assemblies, the wire-to-board solution (connector system with IDC female connector and SMT male connector) has been modified and optimised to meet the increased requirements of the automotive industry as well as modern automation technology. This means that even the most demanding applications, such as in inverters of electric/hybrid vehicles, can be addressed. Reliability in the locked state (e.g. under vibration and shock loads) is just as important as the precise and error-free mating process.

The geometry of the angled IDC female connector and the straight SMT male connector requires a defined force to lock the wire-to-board connection. The user receives a clear acknowledgement (audible, tactile) that the connection has been securely made. Additional guides and widened locking levers reliably prevent contact damage during mating. The connection is released using an inexpensive unlocking tool. With the 50-pin SMC Secure Lock connectors, compact and reliable ribbon cable assemblies can be realised.