However, capturing clear and accurate microscopic images can be challenging due to imaging artifacts.

These artifacts can appear as distortions or anomalies in the captured image and cause analysis errors. In this blog post, e-con Systems explore the five common types of imaging artifacts encountered in microscopic imaging and ways to minimise them.

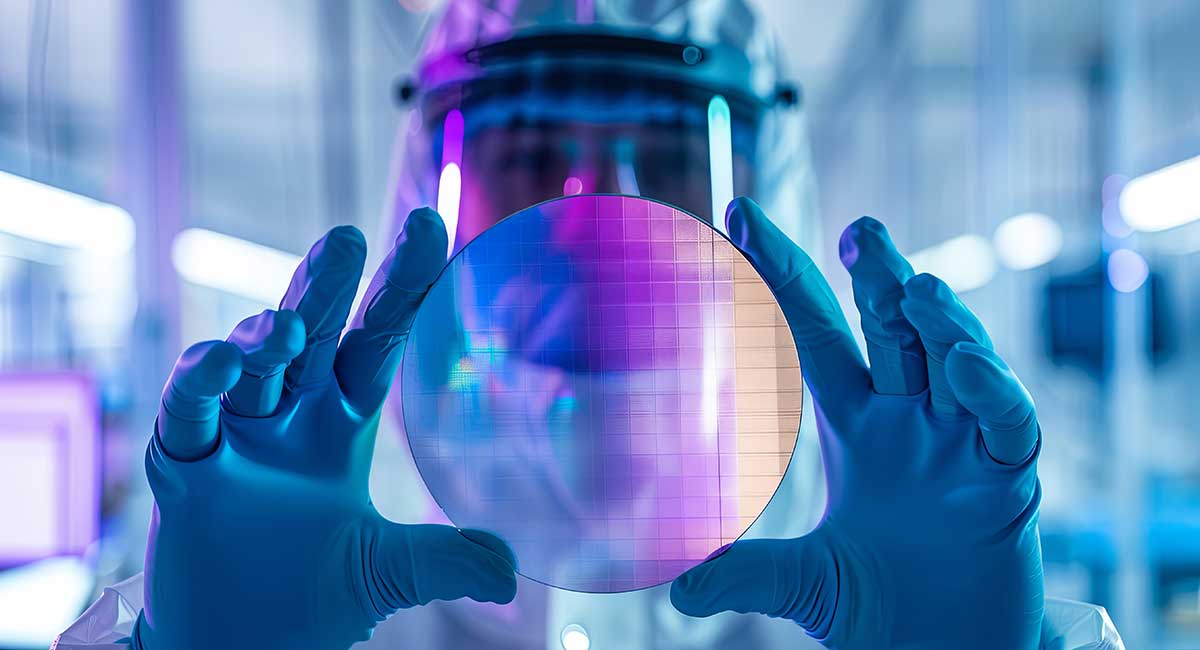

High-definition microscopic cameras are used consistently in the medical and life science industry for the purposes of medical diagnosis, surgical procedures, pathological research, etc. Right judgment of medical conditions/ailments can only be derived from accurate and detailed microscopy.

The fusion of camera and microscopic technology is frequently used in many analytical and research methodologies in medical sciences today. Cameras with microscopic abilities can observe, understand, and diagnose the cellular-level conditions of specimens.

A major challenge prevalent in cellular diagnosis is imaging artifacts, i.e., a feature or a detail in the captured image that is not present in the subject being imaged. These tampered elements on the images can occur due to microscopes’ optical components, image acquisition process, sample/slide preparations, illumination used, and so on. The visual disruption caused by imaging artifacts has tangible impacts on decision-making and patient care.

In this blog, e-con Systems talk in detail about various imaging artifacts and the camera solutions ideal for photomicrography to avoid imaging artifacts.

Five types of imaging artifacts and their causes and solutions

1. Blooming/saturation artifact

Blooming occurs in CCD (Charge Coupled Device) sensors under conditions in which either the finite charge capacity of individual photodiodes or the maximum charge transfer capacity of the CCD is reached.

The electrons generated from photons during exposure are collected in the wells (Figure 1). The maximum number of electrons the pixel can hold is determined by the full well capacity/saturation capacity. The bigger the pixel, the higher the saturation capacity. This also characterises the sensor’s dynamic range. If the generated charge exceeds the full capacity of a pixel during the exposure time, the extra charges tend to flow to the neighbouring pixels. This results in blooming.

2. Pixelation artifact

Pixelation artifacts occur when the magnification level exceeds the image sensor’s capability, resulting in an invisible pixel boundary. These artifacts degrade the image quality and reduce the spatial resolution. This makes the minute details difficult to interpret. For example, the anatomical features inside a cell. As shown in the figure below.

![]()

Temporal noise in a camera image is caused by the aggregate spatial and temporal variation in the measured signal, assuming constant uniform illumination. The characteristics of temporal noise deviate from pixel to pixel and from scene to scene. This type of noise is generally more difficult to remove.

3. Temporal or time-varying noise

There are several types of temporal random noise, here e-con Systems delve into each of them in detail.

Dark noise: dark noise is caused by the current that flows even when no photons are incident on the camera. It is a thermal phenomenon caused by electrons spontaneously being generated within the silicon when the valence electrons are thermally excited into the conduction band. Dark noise is the variation in the number of dark electrons collected during the exposure. Dark noise is independent of the signal and depends on the sensor’s temperature.

Photon shot noise: photon shot noise is the statistical noise associated with the arrival of photons at the pixel. Shot noise depends on the amount of photon flux, the quantum efficiency, and the exposure period. It is independent of the temperature.

Read noise: read noise is generated while producing the electronic signal. This results from the sensor design but also can be impacted by the design of the camera electronics. Read noise is caused by the intrinsic imperfections in the design of all the electronic components that carry, interact with, and amplify the signal before its digitisation. Read noise is independent of the signal level and the temperature of the sensor.

The camera parameters can be tuned as follows to minimise noise artifacts:

- Adjusting exposure time.

- Optimising illumination levels.

- High SNR cameras.

- Image filtering algorithms.

Noise artifacts can also be reduced by the camera cooling mechanism. Cooling can be done in two ways: passive cooling and thermoelectric cooling. These cooling techniques are used to keep the sensor’s temperature in check.

4. Phototoxicity/photobleaching

Live imaging of samples is done with fluorescence microscopy. This mechanism uses string lights to excite the fluorophores. When live cells or specimens are exposed to this strong light for a long time, it may affect the metabolism by impairing sample physiology and even lead to sample death. This is caused by organic molecules present in the sample that absorb light at visible wavelengths and react with oxygen. An oxidised sample molecules become non-functional.

Phototoxicity can be reduced by illumination control. Illumination control can be done by following the given measures.

- Limiting the illumination and fluorophore excitation only to the focal plane.

- Lowering the peak intensity.

- Pulsed illumination.

The overall detection efficiency of the fluorescent signal is the result of several factors of the camera/detector components. Which are:

- Numerical aperture

- Transmission components (mirrors and filters)

- Global shutter and trigger

- Monochrome sensor

- Quantum efficiency

- SNR

5. Compression artifact

In digital pathology, whole slide image scanners are used to digitise microscopic slides. This requires a massive data storage capacity. An average wsf file can range from a few hundred megabytes to several gigabytes. Hence, most WSI systems incorporate image compression algorithms to reduce the file size.

This process can lead to different imaging artifacts, which are mentioned below.

Posterization: posterization is when a continuous gradient appears as a series of discrete steps or bands of colour.

Contouring: contouring is the appearance of false edges in the smooth gradient regions.

Blurring: blurring is caused by the attenuation of high spatial frequencies.

Blocking: blocking when block-based DCT compression methods are used. Block boundaries appear due to the quantisation of the coefficients.

Solutions to avoid compression artifacts:

- Use lossless comparison, that is, PNG or TIFF.

- Optimising the compression settings.

- Denoising, sharpening, and deblurring can be performed during image processing.

- Acquiring higher depth images.

Apart from the artifacts mentioned above, there are other imaging artifacts like stripping artifacts caused by non-uniform illumination across the field of view or camera noise that causes temporary stripes in individual images. Another artifact is the ringing artifact, also known as grip slinging, which comes out as bright and dark image rings around high contrast features, which can be reduced using appropriate deconvolution techniques to enhance the image’s sharpness. Yet another artifact is the checkerboard artifact, which appears as a pattern of alternating bright and dark squares or rectangles in the image. This can be reduced by improving the depth of field.

Artifacts can also be caused by optical aberration. Spherical aberration and chromatic aberration are the two types of artifacts caused by aberrations. Spherical aberration leads to loss of focus, and chromatic aberration leads to the appearance of colour fringes across the image.

Camera parameters to consider for avoiding imaging artifacts

- Quantum efficiency

- Pixel size and density

- Bit-depth

- Resolution

- Signal-to-noise ratio (SNR)

- Dynamic range

Medical cameras offered by e-con Systems

e-con Systems, an industry pioneer, has 22+ years of experience in designing, developing, and manufacturing OEM cameras for various industries, including medical and life sciences.

Recently, they launched the e-CAM200_CUMI2020C_MOD –20MP, a high resolution camera based on the AR2020 image sensor from onsemi’s Hyperlux LP series. It ensures exceptional image quality, achieving a high frame rate at 20MP while seamlessly interfacing with NVIDIA Jetson AGX Orin, Jetson Orin NX, Jetson Orin Nano, and Qualcomm Robotics RB5. It is equipped with support for USB, GMSL, and MIPI interfaces.

e-con Systems also has decades of ISP fine-tuning expertise so that the perfect image processing can be achieved on these platforms.