Automating mineshaft inspection

Advanced positioning sensors and imagery is enabling subterranean mineshaft inspection without risking safety, while minimising downtime. By Jesse Bonfeld, Vice President of Business Development for Sherborne Sensors, & Borys Vorobyov, CEO and CTO of Sight Power.

Regular mineshaft inspection is mandatory in every country having a mining industry, but it results in large losses in revenue due to production being interrupted. Furthermore, engineers must perform inspections in a potentially dangerous and high-risk environment. Promising substantial savings and improvements in safety, Canada-based Sight Power is developing an innovative automated mineshaft inspection technology. Based on mobile laser scanning and high-resolution imagery, it employs Sherborne Sensors’ accelerometers and inclinometers to provide precise positional data and help ensure optimal accuracy and reliability.

Mineshafts are the lifeline to underground mines. Shafts and hoisting systems provide access to a network of openings used to access the underground resource, (typically base and precious metal ore deposits, diamonds or coal), to transport miners and materials and serve as a conduit for ventilation and cooling. They also provide an emergency exit.

Mineshaft inspections are therefore not only vital to ensuring the safe and reliable operation of the mine and its shafts, but are a legal requirement in most countries having a mining industry. Every mineshaft must be closed for thorough visual inspections, typically once a week, while each visual inspection can take between 4-12 hours to complete, depending on the depth of the shaft. This results in large losses in revenue for the operator of the mine, due to production being interrupted.

Moreover, the potential for human error is high, not just due to the lack of light, but because performing the inspection is arduous and fatiguing. Unfortunately, serious mine shaft accidents including fatalities still occur, many of which are caused by human error exacerbated by the dangerous and high risk environment.

The current shaft inspection technique is largely the same as that employed from the dawn of mining; pure visual observation while going down a shaft. While there have been attempts to modernise the process, these have been complementary to the visual method and have never been accepted and fully implemented.

LiDAR leads the way

The mineshaft is a complex engineering entity. From a geometrical and topological point of view, it can be thought of as a cylinder with a diameter of between 5-20 meters and a depth of anywhere between 100-3,000 meters. The shaft contains a multitude of constructional elements including: vertical guides (rails for the conveyances); pipes of various diameters; steel beams; fixing brackets and cables. The mineshaft’s lining is commonly constructed from reinforced concrete or cast-iron ‘tubbing’ rings.

In order to check all of the shaft constructional elements, the conventional procedure is to lower engineers down the shaft in the elevator at a speed below 1m/sec. However, Canada-based Sight Power is working with Shaft Sinkers and Parsec in South Africa to develop their Mobile Shaft Scanning System (MS3), a laser scanning device that is attached to the conveyance that moves up and down the shaft at a significantly higher average speed than conventional manual methods to enable quick and unobtrusive shaft scanning. A realistic 3D image of the entire shaft with all its internal infrastructures can then be rendered and imported into a software package for analysis.

MS3 is based on LiDAR (Light Detection and Ranging) technology and high-resolution imagery. It combines three core elements; Lasers, a Global Positioning System (GPS), and Inertial Navigation Systems (INS), into a single platform allowing the positioning of a laser beam scanning a target to a high degree of accuracy.

.

.

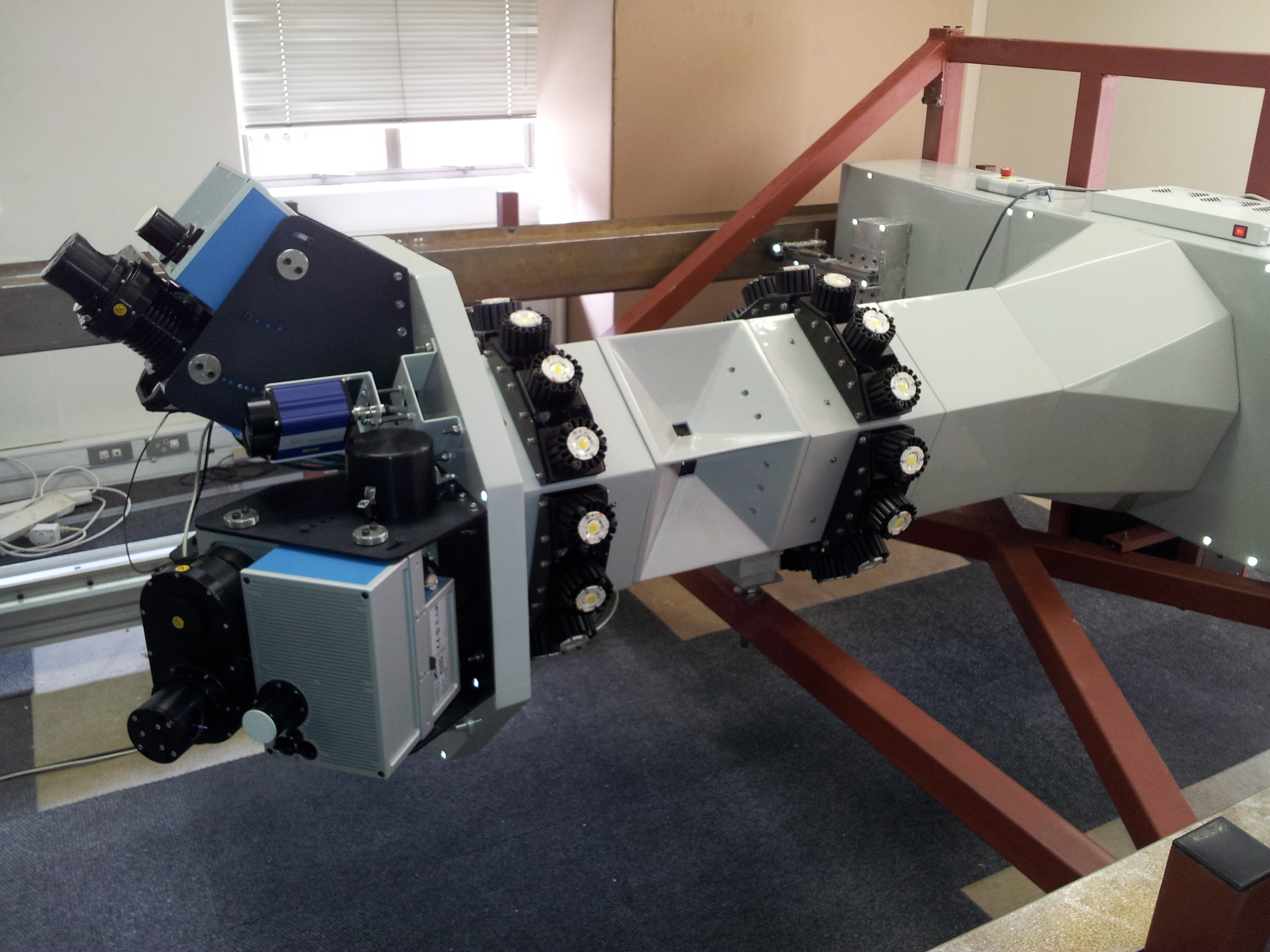

Figure 1: The MS3 prototype system, with camera section being incorporated

LiDAR systems are ideal for mineshaft inspection, because the typical distance from the scanning device to objects within the shaft barrel is only 3-4 meters. However, the fact that GPS signals are not available underground presented a significant challenge in terms of obtaining the highly-accurate geo-reference position data required.

Typically, LiDAR devices are mounted on a mobile platform, with a GPS providing accurate geographical information and an INS recording the precise orientation (pitch, roll and yaw). But in the absence of a GPS, a variety of positional aids are required to assist the INS used by the MS3 system, including inertial sensors such as accelerometers and inclinometers. The development team also had to design a much more sophisticated system capable of achieving measurements to within 5mm accuracy (compared with 20-40mm for common terrestrial systems).

Optimal design

To reduce the risk of failure whilst proving the concept and testing the first prototype unit in a real mining environment, the MS3 hardware designers specified only the most reliable and precise instruments and system components, opting for Sherborne Sensors’ DSIC inclinometers and A323 accelerometers.

Sight Power compared products from a number of suppliers and the consensus was that Sherborne Sensors provided the best match for accuracy, price and reputation. It can often be the case with these types of sensors that they don’t perform as expected. However, Sight Power checked each unit separately before connecting them up to the MS3 system and claims they have proven to be very reliable.

During the laboratory test phase the inertial sensors assisted in mapping and characterising the horizontal test set-up performance, as well as indicating any flex, twist and tilt in the MS3 mechanical housing system. They are also being employed to characterise and understand the mineshaft environment, so that the Sight Power team can refine the MS3 system and its design for optimal accuracy and reliability.

The gravity referenced servo inclinometers and accelerometers from Sherborne Sensors are designed to be very robust and extremely accurate, and are field-proven. Their dynamic range means that their output is more conducive to the volume of data required and allows seamless integration into the MS3 data acquisition system. The fact that these inertial sensors are temperature compensated was a key factor in ensuring accuracy of results, because the temperature can vary dramatically down the length of a mine shaft.

Figure 2: The MS3 unit in the lab, with sensors located on the scanning head

The DSIC high-precision inclinometers measure the amount of roll and pitch of the carriers to give an indication of whether or not the movement down the shaft is well controlled using the shaft guide tracks. Given that the movement of the MS3 system carriers — such as mine cages, skips and counterweights — will vary from normal speed to very slow during the inspection cycle, Sherborne Sensors’ A323 accelerometers measure the performance of the carriers with respect to vibration and acceleration during normal operation as well as during inspection cycles.

Preventing production disruption

With distance and location information accurately determined, the laser pulses from the scanning device yield direct 3D measurements, creating a ‘point cloud’ of data that can be interpreted by sophisticated software in order to build a Digital Spatial 3D model. The initial model of the mineshaft provides an accurate view of current shaft conditions, subsequent scans are then compared against it to determine all changes and their severity, and to identify any construction elements affected.

MS3 will also have the ability to take digital images and combine them with LiDAR data to create a more realistic 3D rendition. When analysing these 3D images, engineers will be able to immediately determine and highlight areas of concern, such as ground movements, cracks in lining, misalignment and deflections of pipes, buntons and guides.

Sight Power believes MS3 will improve mine safety, with a reduction in man-hours spent underground in hostile environments and the early detection of defects. It will also mean increased availability of hoisting time and consequently a significant increase in a mine’s revenue and profitability. Crucially, engineers will be able to detect defects at a much earlier stage, cutting shaft maintenance repair costs and downtime and enabling engineers to address any issues before they become a major safety hazard and operational issue.

According to Sight Power, MS3 has the potential to reduce production stoppage times by at least 50% annually. Moving forward, the company aims to determine whether using clusters of accurate but lower cost sensors such as inclinometers and accelerometers can eliminate the requirement for the INS, which would lower the overall cost of the MS3 system.