Pepping up packaging

GaN semiconductors are relatively commonplace and now the P3EP project moves the spotlight to developing scalable power conversion modules that capitalise on GaN technology for mass manufacturing processes, writes Caroline Hayes.

This article originally appeared in the April '22 magazine issue of Electronic Specifier Design – see ES's Magazine Archives for more featured publications.

Pre-packaged Power Devices for PCB Embedded Power Electronics (P3EP) is a collaborative project which aims to develop compact, lightweight power conversion modules based on GaN, and establish a UK supply chain for PCB-embedded power systems with GaN devices. The dual aims are to make the UK more self-sufficient in power conversion module production, directed at electrification of electronics systems.

P3EP is part of the UK Research and Innovation (UKRI) UKRI’s Driving the Electric Revolution Challenge in which £80 million has been allocated to develop a UK manufacturing capability for electrification, to ensure manufacture and supply of components and to build a sovereign supply chain for zero emission technologies. It is intended to protect the UK industry against future overseas supply chain disruption, such as that experienced during the Covid-19 pandemic, and those feared if the Russian invasion of Ukraine escalates.

Supply chain goals

Challenge director, Professor Will Drury, says: “The coming electric revolution presents an opportunity to put the UK at the forefront of a burgeoning industry, creating manufacturing jobs and prosperity across the country.

“By building a sovereign supply chain, we can help make sure zero emission technologies are truly zero emission, while both mitigating against overseas supply chain disruption and cementing the UK’s place at the forefront of a burgeoning industry.”

The P3EP manufacturing chain is based on GaN pre-packages. As a semiconductor material, GaN has high switching speeds and can contribute to system size reductions. GaN transistors and bare die are available from multiple sources but the UK Research and Innovation project is looking at new packaging and module construction methods which will increase thermal transfer and reduced parasitic effects.

The project identified that embedding power devices into the PCB has proven to be the most advanced way to deliver efficient packaging and power modules.

Pre-packages allow production testing, characterisation, and reliability qualification, giving them an immediate advantage over bare dies. These testing and qualification processes improve yield, cost, and time-to-market. They also use materials optimised for chip compatibility to facilitate system integration.

Partners in the project to build high density converters are Pulse Power and Measurement, The Thinking Pod Innovations (TTPI), Cambridge Gan Devices, RAM Innovations, Cambridge Microelectronics and Compound Semiconductor Applications Catapult.

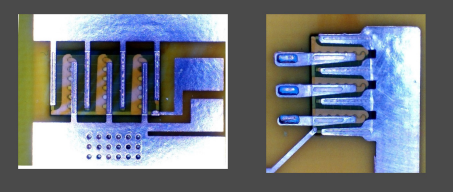

Figure 1. An embedded die with direct plated connection and large area chip interconnect by RAM Innovations

Embedded die packaging

Deeside-based RAM Innovations provides R&D services as well as low and high volume embedded die packaging (EDP) manufacturing. It was founded in 2011 and has worked with Infineon Technologies on embedded PCB technology and the University of Nottingham for PCB cooling and with the University and P3EP partner TTPI in an Innovate UK-funded development program for a PCB embedded die packaging process for high current, fast switching, power converters. A 2019 Innovate UK-funded project saw RAM collaborate with INEX Microelectronics and Paragraf to develop specialist packaging for Paragraf’s graphene Hall-effect sensors.

For P3EP, RAM explains that GaN’s properties can be exploited to develop compact, lightweight, high effiency power conversion modules, with accelerated switching. It reports that modules up to 10 times smaller than those produced using conventional silicon (Si) transistors are possible.

The P3EP project assesses pre-packaged GaN dies, the development of design and manufacturing processes and testing techniques to produce compact, modular converter-in-package devices. RAM’s multi-layer embedded Power Plane methodology produces a package which does not have wire bonds, resulting in “dramatically” reduced parasitic losses, and “significant improvements” in thermal dissipation to increase reliability, claims the company.

The modules to be developed are intended to be used in DC/DC converters used in the electric vehicle (EV) infrastructure to interface batteries and low voltage (legacy) electrical systems. They can also be applied in passenger aircraft, for cabin power distribution and in the power systems of industrial robotics.

“Though the potential of GaN to boost conversion efficiencies and increase power densities is universally acknowledged, making it practical for OEMs to use in their designs is still proving to be challenging,” observes Nigel Salter, general manager, RAM Innovations.

“The automotive, aerospace and industrial sectors need access to module-based solutions that are simple for them to work with, and can be incorporated into existing production flows,” adds Geoff Haynes, business development manager at RAM.

Figure 2. Cambridge GaN Devices debuted the H1 series of commercially available GaN devices at APEC 2022

GaN technology

Another partner, Cambridge GaN Devices launched its first products at APEC 2022. The fabless semiconductor company spun out of Cambridge University in 2016 and its proprietary ICeGaN (Integrated Circuit Enhancement Mode GaN) technology is the basis for the H1 series of four 650V GaN devices. The company’s first commercially available GaN portfolio combines a cascode two-phase amplifier configuration, a single die eMode (normOff) HEMT (high electrode mobility transistor), integrated smart sense and protection features in a single die. The H1 GaN devices deliver up to 50% power loss reduction, compared to legacy silicon dies, says the company. Crucially, the technology is scalable in terms of both power and voltage.