The COVID-19 pandemic unearthed various home truths. For many, this was a new-found appreciation of friends and family, a sense of sentimentality that had previously been taken for granted.

Not only were relationships strengthened through distance, but much of the country was forced to view the world through a new lens. Many observed the lack of traffic as fewer commuters filled the roads. Some became more in touch with the outdoors on their daily walks – exercise being one of the few legal means to leave the house.

For others, the pandemic brought an adaptation to ways of working, whether in a classroom or office sense. Remote working proved so effective that even after the easing of lockdown restrictions, lots of businesses continued its implementation either wholly or through hybrid structures.

With working from home, came a massive increase in the buying, and as such the production, of electronic devices. Of 2,000 people asked about their electronic devices during the pandemic, 12.8% said that they acquired new devices to aid their remote working. A further 10.8% of these respondents said that they simply binned the items they were no longer using – almost matching the figure of those that stockpiled old IT equipment. Only 12.8% had recycled their equipment, highlighting a huge problem for technological waste.

The purchasing of electronics accelerated drastically throughout lockdowns as people sought new forms of entertainment in the shape of televisions, gaming consoles or exercise and health-related technology.

There were, albeit perhaps only a few, positive influences that can be extracted from the pandemic, such as the recognition of a need for more meaningful action regarding sustainability. However, this is hard to remedy with the amount e-waste being improperly disposed of.

Over 40 million unused devices are estimated to be sat in drawers across the country. Changes to legislature were enacted at the start of the year, which legally require retailers to provide a ‘take-back’ service in-store. As well as this, stores with over 400 square metres of floor space are legally obliged to accept electronic waste with dimensions of no more than 25cm on any side or edge. This is called waste electrical and electronic equipment (WEEE).

Counterfeit acceleration

Alongside the growing problem of e-waste, the pandemic saw a more positive explosion of technological innovation, by which quick solutions were created amidst urgent calls for medical equipment. Formula 1 technicians managed to reverse-engineer, design, test and approve the continuous positive airway pressure (CPAP) device, and then produce 10,000 in a month.

The NHS, amongst other global health services, faced shortages of ventilators which was met with a rapid reshuffling of resources helped to meet these needs. It seems a shame that where there’s optimism in humanity, you needn’t look far to also find those looking to exploit and capitalise on misfortune.

A surge in counterfeit products was observed throughout the pandemic, with organised crime being commonly associated with mass crises. Steve Calabria, Founder of Independent Distributors of Electronics Association, said: “Worldwide shortages have opened the door for criminals to exploit the electronic component marketplace.”

Creating ‘dupes’ is made easier through the lack of in-person shopping, as it is harder to assess quality online. Virus-related products can range from fake pharmaceuticals to knock-off medical grade masks. Obviously, the consequences vary depending on the nature of the dupe.

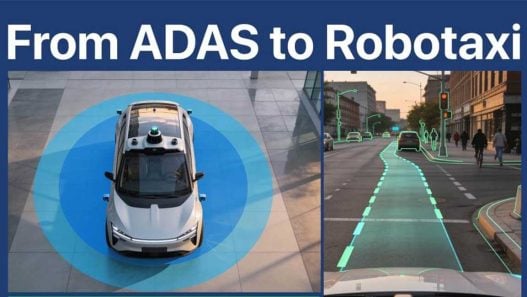

One such electronics industry that has been deeply affected by COVID-19 is semiconductors. Without clear supply chain traceability it is hard to differentiate legitimate components from that in the grey market. Chips can be supplied to manufacturers in healthcare, automotive and defence industries, clearly associating a much higher risk with counterfeits.

What’s next?

Despite government changes to legislation, clearly the problem persists. Something needs to be done to tackle problems of electronic waste and counterfeit production – two pre-existing issues that the pandemic seemed to facilitate in acceleration.

As leaders from around the globe gather in Glasgow at COP26, we eagerly await their thoughts on minimising e-waste. It is also worth paying close attention to tech for good initiatives surrounding supply chain transparency that will hopefully aid sustainability, as well as limit the production of counterfeit devices.