Allegro MicroSystems announces PCB-less 3D magnetic sensor

Allegro MicroSystems, a global specialist in sensing and power solutions for motion control and energy-efficient systems, has announced the A31316 3D Hall-effect position sensor, the latest addition to the company’s 3DMAG line of 3D sensors.

Offered in a small 4 × 4mm body PCB-less package, this sensor is ideal for automotive safety and advanced driver assistance systems (ADAS) applications that require high levels of flexibility and reliable performance in harsh conditions such as powertrain and chassis applications, as well as industrial applications that require linear or rotary sensing.

Powertrain and chassis applications, passenger restraint systems, and shifter systems, are subjected to environmental vibrations and contaminants that can degrade performance. The position sensors used in powertrain and chassis applications typically require support components, like PCBs and capacitors, and – when a position sensor is required in a dirty, high-vibration environment – the assembly of system components can become corrupted by debris and vibration, which can inhibit the performance of the assembly. The same is true for many industrial linear and rotary sensing applications. Designers are challenged to fit robust designs within the allotted dirty, high-vibration space.

OMNIVISION announces 2MP CMOS image sensor

OMNIVISION has announced the miniature 2-megapixel CMOS image sensor in square format for disposable and reusable endoscopes.

OMNIVISION, a developer of semiconductor solutions, including advanced digital imaging, analogue, and touch & display technology, announced the OH02B image sensor – the square 2-megapixel (MP) (1500×1500) resolution CMOS image sensor for gastrointestinal, ENT, orthopedic, surgical, dental, and veterinarian reusable and disposable endoscopes, catheters, and guide wires. It is available in the smallest form factor 2.5 x 2.5mm CameraCubeChip package (OCH2B) for disposable designs. It features OMNIVISION’s AntLinx proprietary technology, which provides the thinnest 4m interface connection directly from the endoscope camera to the camera control unit (CCU) tower.

“The medical industry is moving to single-use endoscopes to minimise cross-contamination and improve patient safety. CCD-based image sensors cannot meet today’s high-performance endoscope requirements and are being phased out,” said Richard Yang, Senior Marketing Manager, OMNIVISION. “CMOS image sensors, such as the OH02B, are critical for the disposable endoscope market because they enable high resolution and small size, generate very low heat at the tip of the scope design, and are cost-effective for one-time use. OMNIVISION’s CameraCubeChip design provides further size advantages and simplifies design resources and the supply chain.”

SICK’s MPB10 sensor bolts-on for continuous condition monitoring

SICK has announced the launch of its MPB10 Multi-Physics Box condition monitoring sensor, a rugged bolt-on device designed to deliver real-time, continuous service data from industrial machines, including electric motors, pumps, fans, and conveyor systems, even in the harshest industry environments.

SICK’s first dedicated condition monitoring sensor, the MPB10, is an all-in-one device designed to make it easy to monitor and interpret vibration, shock and temperature measurement data delivered right from the heart of machines. The MPB10 provides service data to enable more cost-efficient predictive maintenance practices that can improve plant availability, maximise operating life, and protect product and process quality.

The SICK MPB10 measures vibration, shocks and temperature that can be the tell-tale signs of approaching machine failure. Users are provided with pre-processed, concise, and easy to interpret information that can be customised for the machine and process.

Hermetically sealed position sensors offer consistent performance with less power

NewTek Sensor Solutions offers its hermetically sealed position sensors with a 4-20mA current loop output that has become the data transmission standard in the process control industry.

Offering rugged operations and high performance with low power consumption, Newtek’s HI Series of hermetically sealed 4-20 mA LVDTs ensure highly reliable and consistent data output for factory automation, materials testing and packaging equipment applications. Requiring less power than similar DC-operated LVDTs and signal conditioners, these 4-20mA sensors also satisfy low power budgets.

Sustaining accuracy with no errors over long distance transmissions, the 4-20mA current does not degrade over long connections and is less sensitive to background electrical noise. Simple to connect and configure, the 4-20mA output position sensors offer plug and play compatibility with most PLCs and controllers. Units also require less wiring and connections than other signals to reduce startup costs.

Melexis unveils accurate automotive pressure sensor

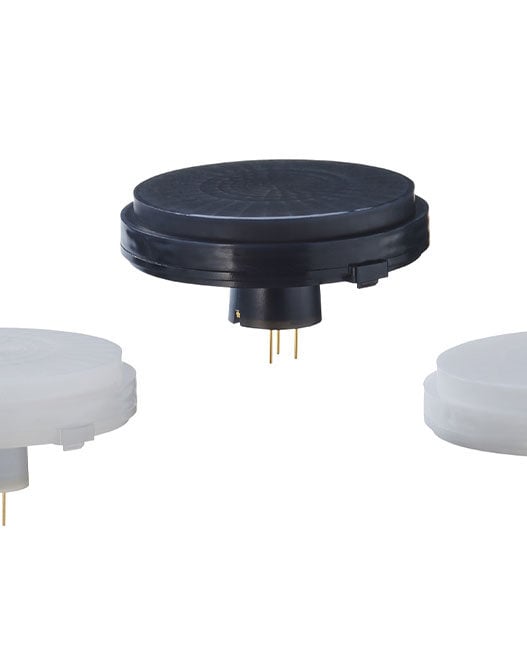

Melexis introduces a new series of integrated pressure sensors. They are intended for use in automotive engine management.

The MLX90824 determines the absolute pressure, then delivers a digital output signal using the SENT protocol whereas the brother product MLX90822 provides an analogue output voltage. These factory calibrated devices measures pressure spans from 1 to 4 bar.

Laurent Otte, Senior Product Line Manager, explains why these sensors help Melexis customers: “An accuracy of +/-0.5 %FS (full scale) is maintained over the course of the sensor’s working lifespan. This accuracy is not impacted by the sensor integration thanks to the PCB-less packaging.”

Very accurate and stable pressure measurements allow optimal engine management to guarantee fuel savings and emission reductions.