Getting close up to fibre optic sensors

Fibre optic sensors are often favoured in electronics applications for their high switching speeds and ability to detect tiny objects.

Because they fit into the small or awkward spaces that other sensors can’t, they can overcome mounting and installation headaches. David Hannaby, Product Manager for Presence Detection at SICK UK, explores the advantages of specifying fibre optics.

The ability of fibre optic sensors to transmit light along a flexible fibre means they can be threaded into narrow locations. They require little power and have little or no detection ‘dead zones’. The detection principle is independent of object colour, shape, or surface, so it can detect virtually any material, and even transparent glue beads. Some fibres can withstand repeat bending without degradation of the signal, making them useful, e.g., in robotic gripper applications.

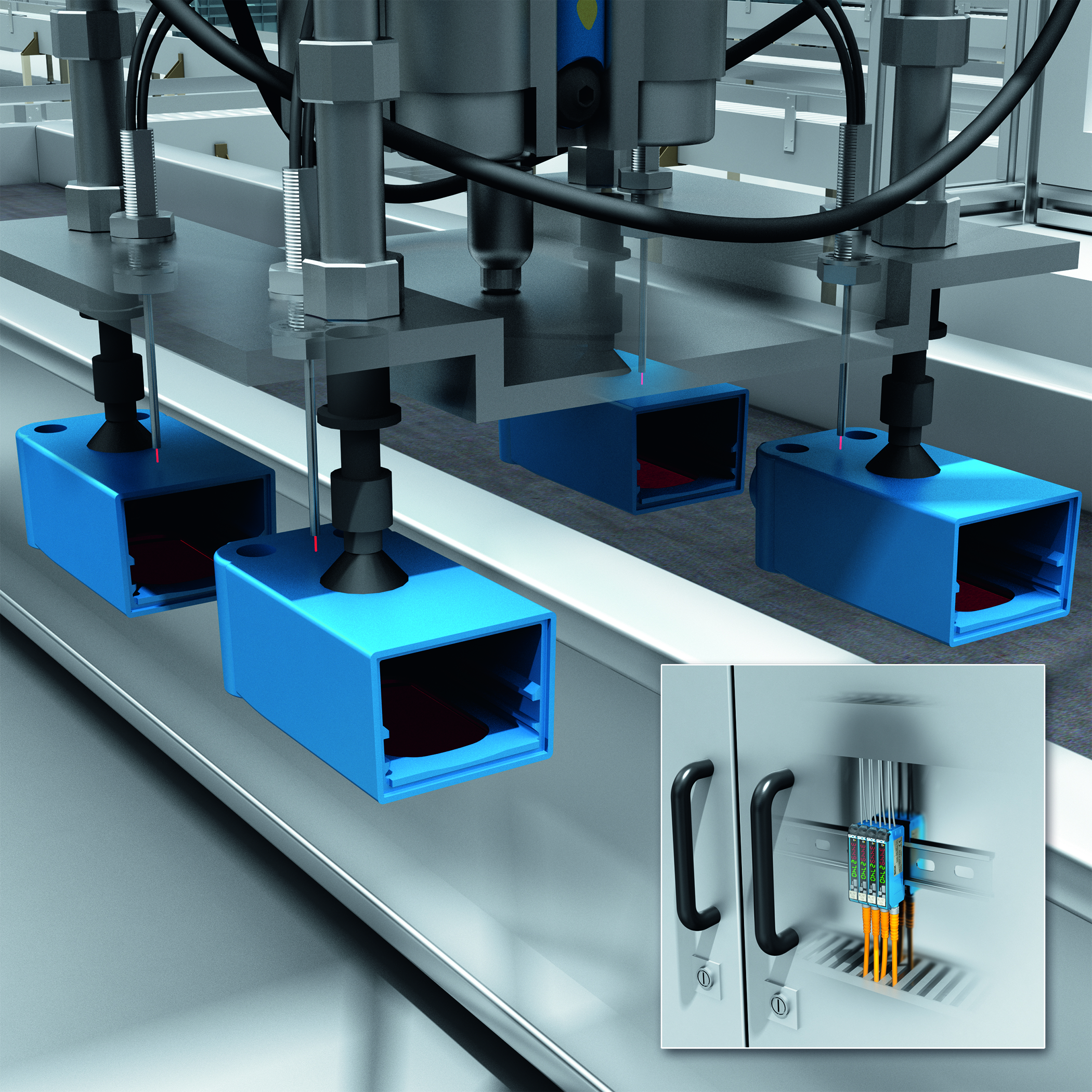

Use case: reliably verifying the presence of a product in a robot gripper throughout a dynamic process.

Total internal reflection

It was the celebrated Irish physicist John Tyndall, who, in 1854, first observed the principle of “total internal reflection”. He noticed that light could be made to travel in an arcing stream of water. The discovery that light energy could be ‘piped’ to a destination in a highly refractive material paved the way for a global fibre optics communications revolution, and the ability to send signals through fibres no wider than a human hair.

Fibre optic sensors work on the same principle. Light is transmitted along a central core, made of a single filament of either glass or polymer surrounded by a less refractive and protective sheath, and a robust outer housing. The light is emitted from the end of the core at an angle of around 60 degrees.

The fibre optic amplifier transmits, receives, and evaluates the light signal, as well as enabling the sensing parameters to be adjusted.

SICK WLL80 fibre optic amplifier

The fibre is the optical component that transfers the sender light from the amplifier and back to a receiver in the amplifier. Vendors offer an extensive range of fibres and heads with versatile options for light dispersal and orientation, as well as for easy mounting. The SICK LLX range offers 500 different fibre types and a wide range of threaded and smooth-sleeve heads, with both axial and radial head alignment available. A useful innovation is that now any length of LLX fibres up to 20m can be specified.

There are extensive ranges of fibres and heads

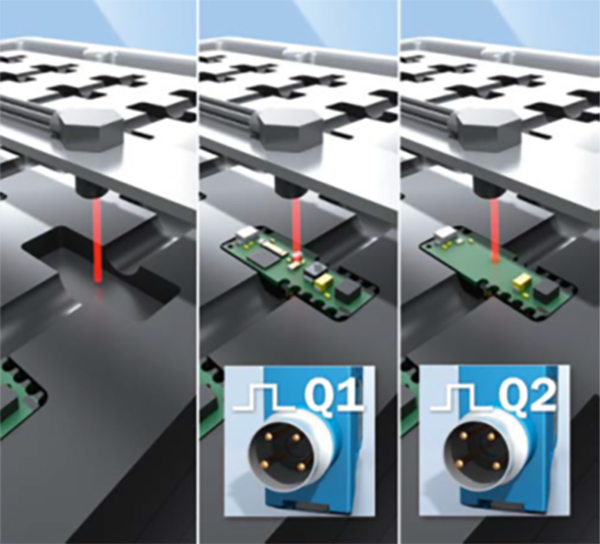

There are two types of fibre optic sensor: proximity and through-beam. In a proximity system, the sender and receiver are combined in a single fibre head. The system is sensitive to the amount of light energy returned to the amplifier. So, precise switching thresholds can be set up to provide an output to the machine control. There is a range of lens heads to direct light emitted from the end of the fibre, depending on how the sensor is mounted. These can be used to focus the light spot to detect very precise small objects, for example for quality checks of small electronics assemblies, e.g., to verify the position of components, or solders on surface mounted boards.

Use Case: Precisely detecting the location of small components surface-mounted on an electronics board

Through-beam fibre optic sensors transmit a light beam between a sender and receiver fibre. As soon as an object passes through the light beam, it is interrupted and the sensor switches. So, for example, the SICK WLL80 system with appropriately specified SICK LLX fibres can detect thin, fast-moving flat objects, such as the leading edge of a semi-conductor wafer, extremely reliably, even where their exact height on the conveyor cannot be defined. A delay timer function in the WLL80 eliminates the possibility of false signals occurring between the expected detection points.

Through beam fibre optic sensors can also be configured with heads that produce a detection grid e.g., to count small components falling from a chute into a tray.

Use case: High speed detection and counting of small components falling into a defined area

What should I consider when specifying a fibre optic sensor?

First, look for an amplifier that minimises inventory. For example, by being able to switch between PNP, NPN or push-pull outputs on the same device, users need only one type of Sick WLL80 fibre optic amplifier for all machine controls.

Ensure the amplifier is compatible with common bus protocols and that sensors can be networked together, without the risk of interference. SICK WLL80 sensors can be organised in banks in a master-slave configuration to enable automatic cloning of parameter settings for multiple devices.

Look for an amplifier with an OLED pushbutton display to make setting or adjusting the sensor in situ quick and easy. There should be detailed setting options for detection parameters and switch points, enabling accurate detection and repeatability.

Using IO-Link could be an advantage in some applications for diagnostics and troubleshooting, as well as rapid replacement.

With so many specification options for fibre optic sensors, choosing and installing them may seem daunting. However, vendors should now offer easy specification guidance on their website, as well as technical sales support to guide you to a reliable and successful application.