A closer look at IP ratings and designing with IP rated connectors

If you have owned a portable device, then you have likely subjected it to unwanted dirt or a drop into liquid. From tablets and wearables to outdoor sensors and industrial equipment, the demand for devices that can withstand these host of environmental factors continues to grow.

By Ryan Smoot, CUI Devices

While IP rated products become more and more commonplace, engineers still need to address Ingress Protection (IP) ratings at the component level to ensure a design’s reliability is not compromised by dust, moisture, or other particulates.

An often-overlooked aspect in the early stages of a design are any external ports, such as audio or USB jacks, which are easy entry points for dust and moisture. If connectors without properly specified IP ratings are chosen for a design, contaminants could damage internal circuitry and impact performance by way of these connectors. To aid engineers in this selection process, this article outlines the IP rating classifications and looks at design considerations when using IP rated connectors.

IP ratings defined

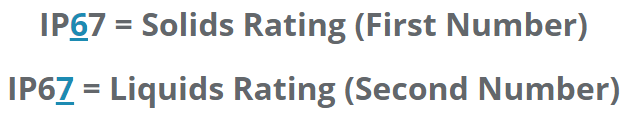

Defined in the IEC 60529 standard as well as national or regional equivalents such as ANSI 60529 in the US and EN 60529 in the EU, IP rating codes contain an IP prefix followed by two numbers. The first number defines solids protection and the second number defines liquid protection.

Figure 1: IP rating code breakdown

The table below provides the specific protections defined by each IP rating code. For example, an IP65 rating means that the connector or part is dust tight and offers protection against low-pressure water jets.

Figure 2: IP rating classifications table

Designing with IP rated connectors

Understanding the various IP rating classifications listed above is important, as selected parts must offer enough ingress protection to fulfill a system’s intended use.

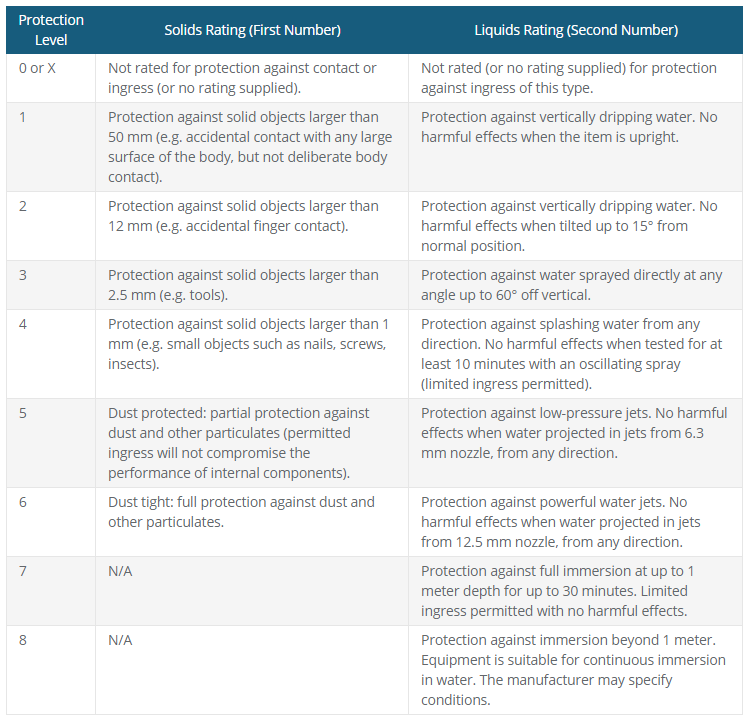

In certain applications, such as cable-to-cable connections in industrial environments, a plug and connector will have to be fully sealed when mated. These fully-sealed connections keep dust and moisture from corroding contacts, disrupting signals, and damaging internal circuitry. Even during operation these connections can be exposed to high-pressure water or full-liquid immersion.

Figure 3: Cable-to-cable plug and connector with locking and sealing interface

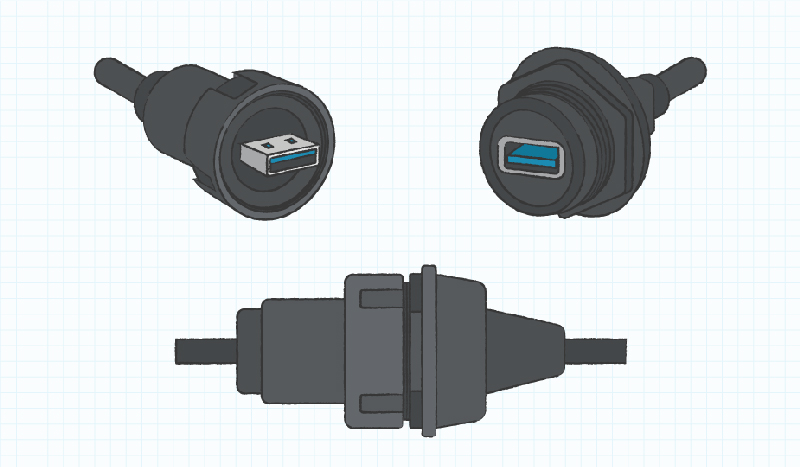

However, the most recognisable use case for IP rated connectors is any external port, such as audio jacks, USB receptacles, or dc power inputs. Ingress protection is needed in these instances to protect internal components and system operation from dust and moisture when no plug or equipment is connected. A properly specified IP rating will ensure that a device’s enclosure is fully sealed in an unconnected state.

When it comes to IP rated plugs and connectors that carry independent IP ratings, it could be easy to assume that they create an IP rated connection, but that is simply not the case. Without an additional sealing mechanism as shown in Figure 3, these basic connections, like a USB cable plugged into your cell phone’s USB port, are still vulnerable to dust and moisture at the connection interface. If exposed to unforeseen dirt or liquid during operation, internal circuitry could be damaged.

Figure 4: Connection interface can still allow dust and moisture ingress

Conclusion

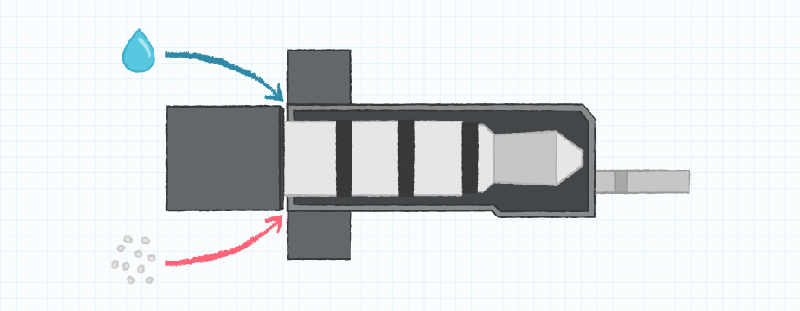

The need for more rugged components continues to grow as portable devices rise in popularity and use. To give engineers added flexibility in their design, CUI Devices’ offers a variety of IP67 rated 3.5 mm audio jacks, USB receptacles, and dc power jacks. These connectors implement a custom-shaped gasket or O-ring to achieve the IP67 classification of dust tight protection and full immersion up to 1m in an unconnected state.

Figure 5: O-ring seal on CUI Devices’ USB connector and dc power jack