Up close and personal - getting the best from your assets

Electronic Specifier Editor Joe Bush talks to Graham Grose and Espen Olsen of IFS Aerospace & Defence, about the company’s IFS Applications enterprise software and how it is assisting clients in the aerospace and defence sector to improve the management of their assets.

Although IFS Applications is predominantly utilised in the aerospace and defence market, the software has applications in numerous other industries including automotive, oil and gas and energy. Despite this IFS stress that it remains a single solution, as Graham Grose, Industry Director - Aerospace & Defence explained: “A key factor for IFS is that we only make one solution (there isn’t one solution for A&D, one for automotive etc), it’s one IFS application which is something that differentiates us from our big Tier 1 competitors, as you don’t have these hugely bespoke, customised, monolithic deliveries.”

The primary function of IFS Applications is to help clients get a better understanding of diminishing defence budgets, execute performance-based logistics and contracting for availability and help them extend the life of their equipment, get better asset visibility and reduce costs etc. To achieve this a key focus for IFS in recent years has been how to get closer to a given asset and, as a consequence, retrieve useful data from it. As such, during the last couple of years IFS has been working closely alongside one of its flagship clients, Emirates, performing a variety of technology demonstrations in the industry. Grose continued: “Although the civil aviation industry is (quite rightly) heavily regulated, our clients are still keen to be at the cutting edge of technology and take any advantages that technology can give.”

Applications for Applications

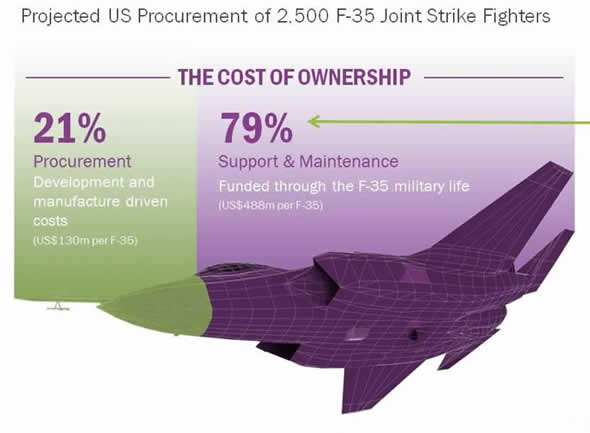

To bring an example of this to life, IFS was heavily involved in the biggest defence deal in history - the F-35 Joint Strike Fighter. In a typical high value military fast jet project it is interesting to note that only 20-30% of the project’s whole life costs are usually related to the development and manufacture of the aircraft. Seventy-eight percent is taken-up by project support and maintenance (and this is where IFS is involved). To put that into some perspective, improving support and maintenance processes of a modern fast jet could typically contribute continued savings of ten percent in this area – a figure that could facilitate the funding for another 190 on a large global fleet. Indeed, the potential savings in this area cannot be underestimated. Figures from the US Airways Group shows that in a hypothetical commercial flight carrying 100 passengers, it takes the fares and fees from 99 of those seats to cover all of the flight’s costs. Therefore, a ten percent reduction in maintenance costs could lead to a doubling of profits.

Commenting on the F-35 project, Grose added: “We worked with the OEM (in this case Lockheed Martin), on how they and their partners can deliver this PBL (performance-based learning). This is very topical, because the first big meeting took place recently between the Ministry of Defence (MOD), Lockheed Martin and BAE, and the first moves were put in place for RAF Marham to receive the F-35 in 2018. We’ve been part of the F-35 programme since 1999, all the way through from the competition phase, and we deliver the part of the project that links the aircraft to the autonomic logistics system – i.e. the ability to understand the aircraft and the faults and requirements that are coming from it prior to landing so that engineers can be on hand with the correct spares, tools and equipment to improve the turnaround time of the asset.

“Being able to get closer to the asset represents an opportunity for all software providers. What IFS offer is a very flexible technology that can adapt to enable customers to take advantage of emerging technology. If you take the example of augmented reality (which is something that’s right at the cutting edge of technology) it has enormous potential but is relatively too unproven for us to bring in our own augmented reality solution at the present time. However, we do have a partner who provides that. So we are able to demonstrate how a technician positioned somewhere remote from the asset is able to actually diagnose a fault and give an engineer a solution to fix it,” Grose continued. This means that solutions will begin to move to being interfaced with the enterprise solution, with feeds of maintenance information being two-way and in real time.

Another example where IFS Applications has been making a significant difference for some time is at Swedish automotive company Saab. Espen Olsen, Director, Business Development & Sales, IFS Aerospace & Defense Center of Excellence, picked up the story: “Saab has replaced over 100 legacy systems, building on a relationship with IFS spanning more than ten years. We’ve supported Saab delivering PBL contracts for some time - allowing them to further integrate with their customers. These PBL contracts are an industry differentiator for us.”

Saab’s CIO, Mats Hultin commented: “Our partnership with IFS is a major step forward in Saab’s ability to provide world class information management solutions to our customers.”

Making sense of big data

Big Data is a common industry buzzword these days and when IFS talks about ‘getting closer to the asset’, it is primarily concerned with access to data. The sheer amount of data being generated from every aircraft sortie, for example, is much more than it was even a year ago, so how that data is used to obtain sensible and useful information from that asset is vital. Olsen added: “Getting closer to the asset means getting access to more data. Some of the OEMs are very protective of that data - they don’t necessarily want to give it to users or customers, so we focus a lot on R&D to try and utilise this data in a better way.”

IFS Applications consists of a selection of software modules and, on identifying the scope of a client’s business, IFS can help the client pick and choose any of the modules available, put them together and configure the client’s solution around it - meaning the client doesn’t end up with something they don’t need.

Olsen continued: “A typical example of a defence end user system would consist of some maintenance modules, some sales and services, supply chain (inventory, purchasing etc.), manufacturing and components, and complex MRO (maintenance, repair and operations). Modules can be added on as and when appropriate. This also means that we can accommodate customers of all sizes and, for a customer using only a few modules, IFS Applications will be a fraction of the cost of a client that’s using everything.”

Summary

In conclusion Grose commented: “We ultimately provide a disruptive technology and that’s how we compete with some of the larger Tier 1s. We don’t sell big blocks of monolithic technology where the client has to ‘take it or lump it’ - we’re asking customers what they need and then we map the system to customer requirements. It’s a very attractive model for clients as they can mould their delivery and save an enormous amount of money in the process.”

Commenting on the impact IFS Applications has had on its clients, Olsen concluded: “Some of the early adopters have been able to reduce the scope of their modifications by 85%. Tailor-made software is no longer required which not only saves them a whole lot of money, it’s going to be a better fit to their requirements and their business.”