While engineers have long optimised electronics for performance, efficiency, and form factor, a shift is now underway that places human interaction at the centre of electronic design. As devices become more integrated into daily life, from wearables and embedded systems to medical and industrial electronics, how a product feels and fits is emerging as a measurable engineering variable rather than a subjective afterthought. Poor ergonomic design contributes to device abandonment, non-compliance in medical settings and increased injury risk, yet ergonomics is rarely quantifiable in early-stage design, leading to reliance on subjective feedback, or ‘trial and error.’ Here, Dr Jae Son, CEO and Founder of tactile sensor specialist PPS, outlines the role of tactile sensing in helping to embed ergonomics into electronic design.

Tactile sensing is gaining momentum as one of the enabling technologies reshaping how electronics are refined. Rather than relying on trial and error or late-stage user feedback, engineers can now embed pressure and force measurement into the design process itself. This marks a transition toward data-led ergonomics, where comfort, effort and fit can be engineered with the same rigour as electrical performance.

As electronics continue to migrate onto the body, designers must optimise for how devices are worn and used, not simply what they do. Market demand is already reflecting this shift. Consumer wearables, medical devices and augmented reality systems increasingly compete on comfort and usability, while industrial electronics face growing scrutiny around musculoskeletal strain and long-term operator health. Ergonomics is therefore moving from a human-factors concern into a core design parameter with commercial implications.

The role of tactile sensing

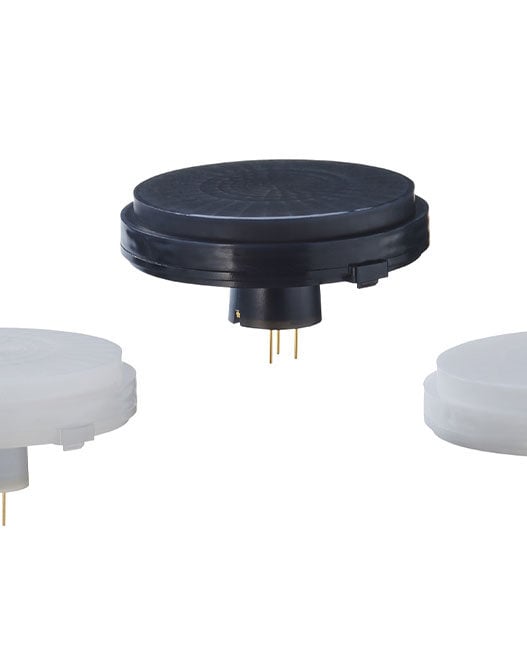

Traditional fit testing remains largely subjective, shaped by individual perception and limited sample sizes. Tactile sensing introduces a scalable alternative by converting physical interaction into quantitative data. Pressure and force sensors can be integrated into prototypes, test rigs or evaluation tools to capture real-time contact behaviour. Engineers can then visualise pressure gradients, movement patterns and localised load concentrations that were previously invisible.

This capability aligns closely with broader electronics trends toward sensor fusion and high-resolution data capture. By using embedded capacitive sensor arrays, developers can generate detailed maps showing how forces distribute across contact surfaces such as a glove gripping a tool or a headset resting against the skull. Design decisions can then be guided by measurable interaction data rather than anecdotal feedback.

Industry research supports this direction. Deloitte’s 2021 Connectivity and Mobile Trends survey found that 39% of wearable users stopped using a device because it was uncomfortable to wear. As electronics markets mature, comfort and fit are becoming decisive factors in long-term adoption, differentiation and regulatory acceptance. Sensor-based evaluation enables issues to be identified earlier, reducing costly redesign cycles later.

Emerging use cases shaping 2026

Several application areas illustrate how tactile sensing is likely to influence electronics development over the next two years. Head-mounted devices such as AR headsets and sleep apnoea masks must maintain stable contact while accommodating a wide range of anatomical variation. Pressure-sensing headforms allow engineers to compare designs objectively and reduce pressure peaks that lead to discomfort or slippage.

In industrial electronics, poor tool ergonomics contributes to fatigue and injury. Sensor-enabled gloves and instrumented test rigs allow engineers to study force distribution across the hand and wrist during real use. A 2016 study in Applied Ergonomics demonstrated that pressure-mapping gloves could reliably identify injury risks in repetitive tool use, highlighting the role of tactile data in safer interface design. These use cases reflect a broader trend toward electronics that adapt to the human body rather than forcing users to adapt to the device.

Calibration and credibility

For tactile sensing to influence electronic design meaningfully, data quality is critical. Calibration techniques that account for material interfaces, geometry and environmental conditions are becoming central to reliable measurement. Application-specific calibration improves repeatability and confidence, which is especially important in safety-critical electronics.

As regulatory expectations tighten across medical, aerospace and automotive sectors, quantifiable ergonomic validation is likely to become a standard requirement rather than a differentiator.

The ability to capture pressure and force data during real-world use is already changing how engineers approach design trade-offs. In 2026, tactile sensing is expected to sit alongside vision, motion and environmental sensors as a foundational input to human-centred electronics. The result is a shift toward products that are not only smarter, but demonstrably more usable.

With over 25 years of experience in tactile sensing, PPS is helping to make comfort and fit measurable in electronic design. As ergonomic performance becomes a competitive and regulatory concern, tactile sensing stands out as one of the technologies shaping the next phase of electronic innovation. To find out more about PPS’s use of tactile and pressure sensors visit its website.