This new addition is engineered to provide precise linear and angular position measurements, even in environments with disruptive magnetic stray fields. The HAR 3920 is developed in compliance with ISO 26262 standards and meets ASIL C requirements, making it a reliable choice for automotive safety systems up to ASIL D level. This sensor is ideal for various applications, including measuring the position of accelerator pedals or throttle valves, and can also function as a non-contact potentiometer. TDK plans to commence production in April 2024, with sample units already available upon request.

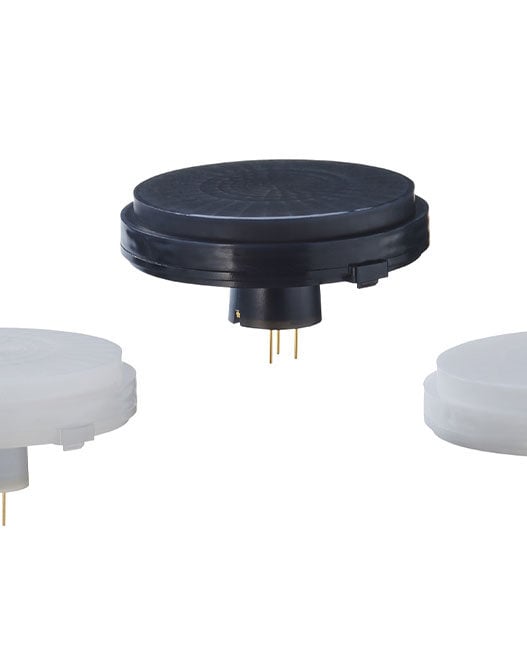

The HAR 3920 distinguishes itself with a dual-redundancy design, incorporating two independent sensor dies within a single package, connected electrically to the pins on one side. This innovative stacked-die structure guarantees consistent output signal characteristics by aligning both dies to the same magnetic field position. Employing Hall technology, the sensor is capable of measuring both vertical and horizontal components of magnetic fields, effectively neutralising the impact of external magnetic stray fields with a specialised array of Hall plates. It can accurately measure a full 360° angular range and linear movements using a straightforward two-pole magnet, ideally positioned in an end-of-shaft setup above the sensor’s sensitive area, enabling precise rotation angle detection. The sensor also supports robust off-axis measurements, immune to stray fields.

The HAR 3920 features a linear, ratiometric analog output signal that includes passive wire-break detection, making it compatible with both pull-up and pull-down resistors for added versatility. It also provides a switch output (open drain), based on the calculated position data or other variables in the signal path, granting users the ability to customise on/off switching points, logic, and polarity.

With on-chip signal processing, the sensor calculates the angle from the magnetic field components detected by each die, translating this data into an analog output signal. Users have the flexibility to tailor key parameters such as gain, offset, and reference position via programmable non-volatile memory.

Designed to meet the rigorous demands of both automotive and industrial environments, the HAR 3920 operates within an ambient temperature range of -40 to 160°C, depending on the voltage supply range. Its compact and versatile design is offered in a sixteen-pin SSOP16 SMD package, ensuring it meets a broad array of application requirements.