The patented technology of the IHM Series is widely considered an improvement over traditional ECKO (Eddy Current Killed Oscillator) topology that was previously the standard in aerospace applications.

Indirect lightning and dielectric ruggedness meet the requirements of today’s composite aircraft and challenging applications such as landing gear, thrust reversers and flight controls.

Features of Honeywell’s IHM Series Aircraft Proximity Sensors that help increase flight hours and therefore revenue by reducing maintenance requirements include enhanced vibration and EMI specifications that withstand extremely high vibration applications.

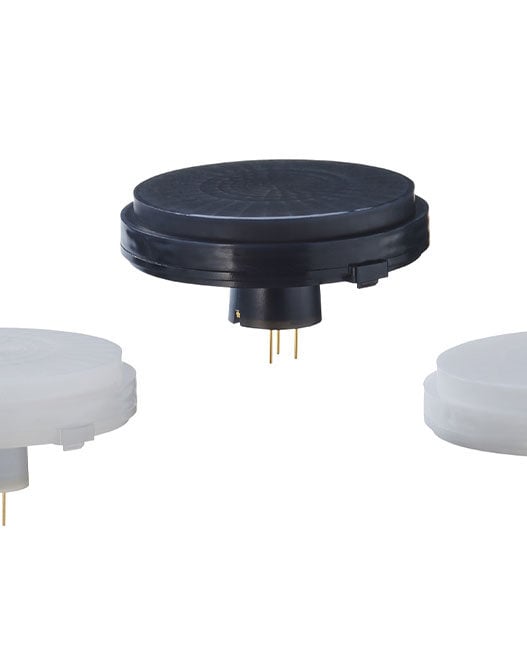

Packages are fully hermetically sealed, providing long term reliability in very harsh environments by eliminating potential contamination of the sensor. Honeywell has also developed an innovative method of hermetically sealing wire-lead (pigtail) configurations.

Devices have an integral health monitoring capability with a third output state indicating if the sensor is healthy or failed, thereby reducing maintenance time, delayed flights and lowering overall maintenance costs over the aircraft lifetime.

The non-contact design of the IHM Series can sense the presence or absence of a target, even in dirty and challenging environments, eliminating mechanical failure mechanisms, reducing wear and increasing durability, all of which increases reliability and minimises aircraft down-time.

Applications for Honeywell IMH Series Aircraft Proximity Sensors include doors (open/closed position, locked status); cargo loading latch detection (pallet locked); evacuation slide door lock mechanism; thrust reverser actuation system (TRAS), (stowed or deployed status); flight controls (flap/slat, spoilers); and landing gear (uplock, downlock and weight on wheels (WOW)).