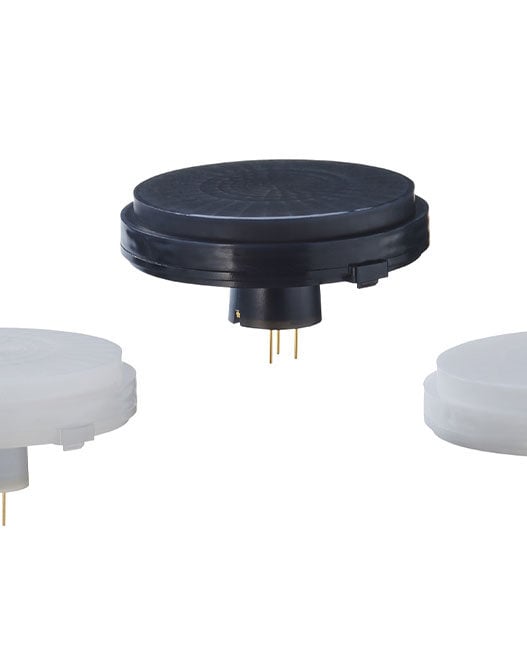

As an expansion of its XENSIV current magnetic current sensor family, the new sensors are housed in a 300-mil package. With a total error of only 0.7% over temperature and lifetime, these products offer the highest accuracy on the market.

The new XENSIV current sensors are available in six different pre-programmed current ranges: 16, 20, 30, 35, 40, and 50A. The 300-mil package offers both reinforced and basic isolation as well as a creepage distance and clearance of 8mm for high-voltage applications.

To minimise power loss, these sensors feature an integrated current rail with a typical insertion resistance of 550µΩ. They enable bi-directional AC and DC measurement through an analog interface and include two rapid overcurrent detection outputs for robust power circuit protection.

In an exclusive interview for Electronic Specifier, Srivats Rajasekaran, Senior Manager, Product Marketing at Infineon Technologies, emphasised that with a robust design and advanced sensor technology, the new XENSIV current sensors are designed for automotive and industrial applications.

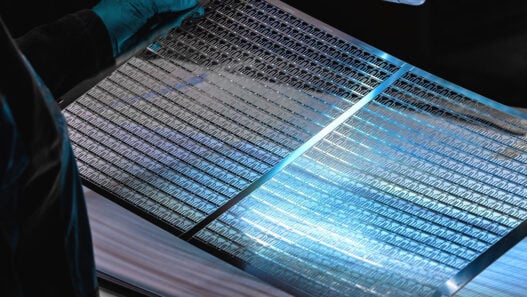

The 300-mil package as a sensory housing unit

“Our 300-mil package, housed in our state-of-the-art manufacturing facility in Batam, Indonesia, is designed to provide a robust and reliable environment for our XENSIV current sensors,” Rajasekaran said.

This package ensures that the sensors can withstand the harsh conditions often associated with high-voltage power conversion applications.

With a strong focus on quality and reliability, these sensors are guaranteed to deliver accurate and consistent performance even in the most demanding environments.

Unmatched accuracy in coreless magnetic sensing

Infineon’s latest XENSIV current sensors offer the highest accuracy in coreless magnetic current sensors available on the market today.

Rajasekaran added: “This is achieved through our proprietary back-end calibration process, which minimises accuracy errors associated with lifetime and temperature drift.”

These sensors boast the lowest drift compared to competing products, ensuring that the customers can rely on precise current measurements in their applications.

Diverse industrial and automotive applications

The XENSIV current sensors are perfectly suited for a wide range of high-voltage power conversion applications, including on-board chargers (OBC), power supply units (PSU), industrial drives, photovoltaic (PV) inverters, and more.

“These applications require up to 1.5kV isolation and 8mm clearance and creepage, which our sensors are designed to provide,” Rajasekaran explained.

With their high accuracy and reliability, these sensors are the perfect choice for customers seeking to optimise their power conversion systems.

The benefits of six pre-programmed current ranges

“Our XENSIV current sensors are available in six different pre-programmed current ranges, offering our customers the flexibility and convenience they need to easily integrate our sensors into their applications,” Rajasekaran said.

The pre-programming allows for easy plug-and-play usage, eliminating the need for complex configuration or calibration. Moreover, the sensitivity setting enables customers to utilise the full output voltage swing, ensuring that the signal is optimised for feeding into analog-to-digital converters (ADCs).

“While our competitors may offer similar features, our proprietary technology and manufacturing expertise ensure that our sensors deliver unparalleled performance and reliability,” Rajasekaran commented.

Achieving ultra-low power dissipation through coreless sensing

Power loss is a critical concern in power conversion applications, where even small inefficiencies can lead to significant energy losses.

Rajasekaran added: “Infineon XENSIV current sensors help minimise power loss by providing accurate current measurements, which are essential for efficient power conversion from AC to DC.”

By using these sensors, customers can ensure that their power conversion systems operate at peak efficiency, reducing energy losses and minimising their environmental impact.

Protective features for power circuit integrity

“In our XENSIV current technology we incorporate a range of features designed to protect power circuits, including in-built overcurrent detection (OCD) with two dedicated OCD pins,” Rajasekaran explained.

In this way, these pins provide feedback to the microcontroller and gate driver, enabling rapid response to overcurrent events and ensuring the safe operation of the power circuit.

“This enables the gate driver to perform a fast shutdown during an overcurrent event, reducing potential harm,” Rajasekaran underlined. This dual-path architecture ensures redundancy and ultra-fast reaction times which is vital for protecting delicate power stages like Silicon Carbide (SiC) MOSFETs or IGBTs.

By integrating OCD into these sensors, customers are provided with an additional layer of protection and reliability, reducing the risk of damage to their power conversion systems.

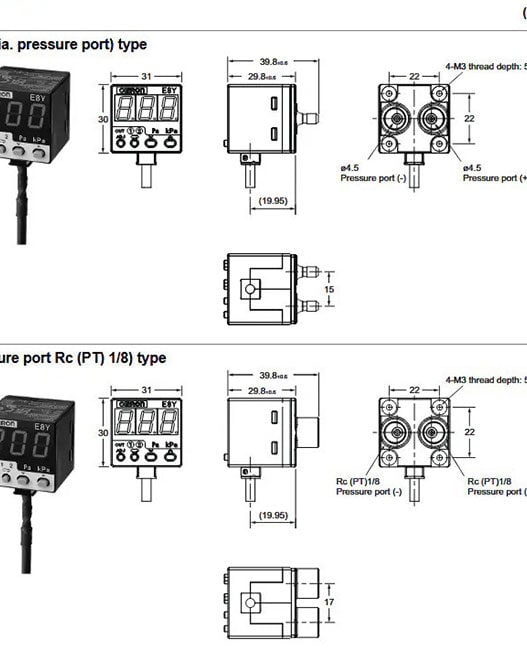

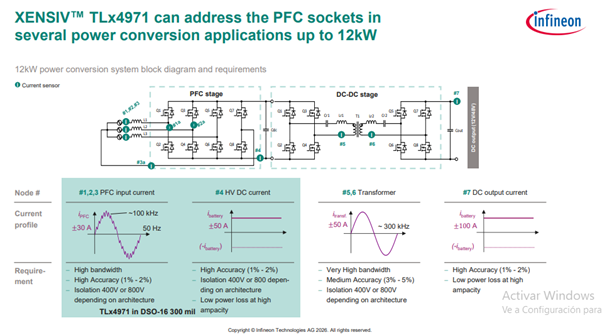

Use cases for the new XENSIV current sensors

Below is a typical power conversion block diagram (OBC, PSU, DC fast chargers) where the TLE4971 can be used.

The role of patented temperature and stress compensation

“Our XENSIV current sensors feature a patented temperature and stress compensation mechanism, which ensures that our sensors deliver accurate and reliable performance even in the most challenging environments,” Rajasekaran underlined.

This mechanism uses built-in temperature and stress sensors to compensate for errors caused by these factors, guaranteeing that the sensors maintain their accuracy and reliability over time.

“By integrating this feature into our sensors, we provide our customers with a high degree of confidence in the performance and reliability of their power conversion systems,” Rajasekaran said.

Eliminating hysteresis and saturation via coreless design

Unlike traditional current sensors with magnetic cores, Infineon XENSIV current sensors are coreless and devoid of any magnets, eliminating the risk of hysteresis and saturation effects.

Rajasekaran added: “Over the past 30 years, we have refined our Hall technology to be highly linear with low offset errors, ensuring that our customers can rely on accurate and consistent current measurements.”

This freedom from hysteresis and saturation effects is a key advantage of the XENSIV current sensors, making them the ideal choice for applications where accuracy and reliability are paramount.

The power of differential sensing principle

The XENSIV current sensors employ a differential sensing principle, which provides stray-field robustness and immunity to external magnetic fields.

“This feature ensures that our sensors deliver accurate and reliable performance even in environments with high levels of magnetic interference, making them the perfect choice for applications where stray fields are a concern,” Rajasekaran explained.

By utilising two integrated Hall elements to measure the magnetic field gradient, the XENSIV current sensors effectively cancels out common-mode interference from distant sources.

Final considerations

XENSIV current sensors also feature integrated, programmable EEPROM non-volatile memory to store sensitivity settings and compensate for temperature and stress errors.

“While customers typically don’t modify these settings, the EEPROM allows for further flexibility and customisation when needed,” Rajasekaran commented.

On the other hand, interested customers can use the Eval board to test the current sensor performance. The Eval board is optimised for 3-phase 50A current flow with 3 current sensors (1 for each phase).

In summary, with billions of XENSIV units shipped globally, Infineon is one of the world’s most trusted manufacturers of sensor technology.

“XENSIV current sensors will play a critical role in shaping the future of power conversion, enabling our customers to create more efficient, reliable, and sustainable systems,” Rajasekaran concluded.

At embedded world 2026 in Nuremberg, Infineon will also showcase the highlights of its newest XENSIV 60GHz CMOS radar sensors with integrated processing for stand-alone presence detection and advanced radar sensing.

About the author:

Diego de Azcuénaga, Contributing Writer