Here, Ross Turnbull, Director of Business Development and Product Engineering at Swindon Silicon Systems, explores how ASICs can address key challenges in medical device design and help drive the future of healthcare.

Smart sensors for smart treatments

Smart sensors are transforming medical devices, offering increased functionality and enabling continuous, real-time monitoring. These devices not only improve the quality of treatments but also empower patients to take a more active role in managing their health.

A standout example is wearable technology — now a cornerstone of modern healthcare. With wearable monitors, it’s possible to track vital signs such as heart rate and blood glucose in real time. Particularly beneficial for monitoring chronic conditions such as diabetes, these devices provide a continuous stream of data for both patients and healthcare professionals to view.

Similarly, smart bandages currently being developed by researchers could collect data on wound healing to send to a mobile app or healthcare provider, allowing for more personalised treatment. Researchers at Stanford University have even developed a smart bandage that applies electrical stimulation in response to specific

conditions detected in the wound, to accelerate healing.

Smart sensors are also advancing surgical capabilities, with robotic systems already present in some operating rooms. The da Vinci surgical systems are some of the most widely used, with over 14 million surgical procedures completed. Robotic systems like these enhance precision and control in minimally invasive surgeries, leading to faster recovery times and a lower risk of complications. As sensor technology evolves, these systems are likely to become even more advanced, with features such as real-time tissue analysis, enhanced haptic feedback and potentially even autonomous capabilities.

Hurdles in medical sensor design

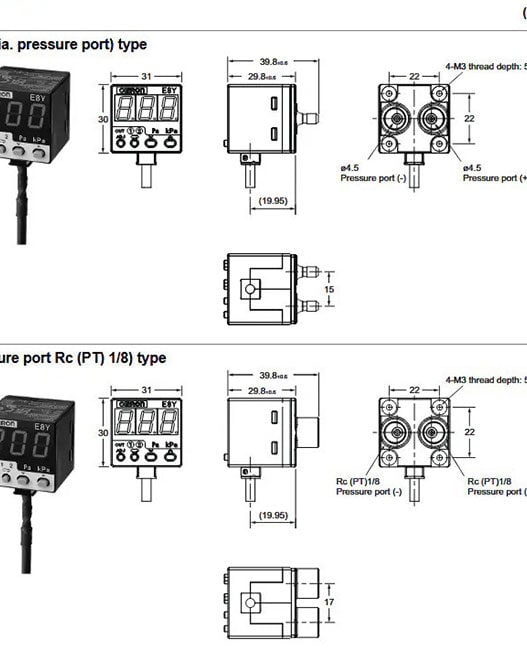

Despite their potential, developing smart sensors for medical technology presents several challenges that must be addressed to create high-performing, reliable devices. One of the primary challenges is the need for miniaturisation. Wearable and implantable devices must be both lightweight and compact while maintaining high functionality. The challenge lies in fitting sophisticated sensing components, such as signal processors and communication modules, into minute devices like smart bandages, pacemakers or cochlear implants. Additionally, dissipating heat is more challenging in smaller devices, requiring careful consideration of components and an efficient thermal management strategy to prevent dangerous overheating.

Smart sensors also require significant processing power, which can quickly drain battery life. For wearables and mobile health applications, balancing performance and long battery life is critical for patient convenience and compliance. This challenge is further compounded by the need for always-on functionality, requiring real-time data processing, which is power-intensive.

Data processing itself poses challenges, as medical applications demand near-instantaneous data collection and feedback and even the slightest latency can have catastrophic consequences for the user. Off-the-shelf integrated circuits (ICs) often struggle to meet these demands, as they are not designed with specialised capabilities such as rapid signal acquisition, high-speed data conversion or parallel processing. Built for a wide range of general-purpose uses, their inherent design trade-offs can introduce bottlenecks in performance, making them ill-suited for medical applications where every millisecond counts.

The diversity of medical applications further complicates sensor design, as the required functionalities vary significantly across different devices. In the case of smart bandages in direct contact with open wounds, biocompatibility is crucial. This ensures the bandage can function in the moist, changing environment of a wound without degrading or releasing harmful substances over time.

Meeting unique demands like this is challenging for standard ICs. Depending on the application, designing medical sensors could involve developing novel sensor materials and specialised signal processing techniques or enabling integration with other devices, such as Cloud-based systems, to ensure optimal functionality. For this

reason, custom-designed sensors are often far more suitable than standard ICs for meeting the exacting standards of each application.

Maximising potential with custom designs

Custom components are vital for unlocking the full potential of medical sensors, enabling manufacturers to tailor solutions to specific challenges and create optimised, high-performance systems. Mixed-signal application specific integrated circuits (ASICs) are particularly beneficial in medical sensors. By integrating signal processing capabilities into a single chip, mixed-signal ASICs eliminate the need for multiple discrete components. This not only reduces the size and weight of the device but also enhances reliability by minimising potential failure points.

Additionally, ASICs can be precisely customised to meet unique requirements of individual medical applications, ensuring peak sensitivity, accuracy and power efficiency.

For example, ASICs can incorporate custom signal processing algorithms to handle real-time data with minimal latency, addressing the critical need for instantaneous feedback in medical devices. Their ability to integrate seamlessly with wireless communication modules and Cloud-based systems also enhances the versatility of medical sensors, paving the way for smarter, more connected healthcare solutions.

Selecting an experienced partner

Designing sensors for medical devices demands both technical expertise and a thorough understanding of regulatory frameworks. The healthcare industry operates under rigorous compliance and data protection standards to maintain patient safety and confidentiality. Partnering with an experienced ASIC supplier is critical for navigating these complexities and ensuring a smooth development process.

As the demand for more sophisticated and connected medical devices grows, smart sensors will remain at the forefront of innovation in healthcare. Looking forward, custom IC solutions will be essential to harness the potential of these technologies and tackle the challenges in designing effective medical devices.

This article originally appeared in the April’25 magazine issue of Electronic Specifier Design – see ES’s Magazine Archives for more featured publications.