Colour recognition is perhaps one of the most critical vision functions but is currently missed in research due to the difficultly of downsizing the components needed. Conventional colour sensors consume a large amount of physical space and are not that accurate.

The researchers have developed a unique stacking technique that offers a solution to this problem.

“The ultimate purpose of our research is to develop a micro-scale camera for microrobots that can enter narrow spaces that are intangible by current means, and open up new horizons in medical diagnosis, environmental study, manufacturing, archaeology, and more,” says assistant professor of Physics Sidong Lei, who led the research.

He says the van der Waals semiconductor-empowered vertical colour sensing structure offers precise colour recognition capability which can simplify the design of the optical lens system for the downscaling of the artificial vision systems.

Ningxin Li, a graduate student in Dr. Lei’s Functional Materials Studio who was part of the research team, says recent advancements in technology make the new design possible.

“The new functionality achieved in our image sensor architecture all depends on the rapid progress of van der Waals semiconductors during recent years,” says Li. “Compared with conventional semiconductors, such as silicon, we can precisely control the van der Waals material band structure, thickness, and other critical parameters to sense the red, green, and blue colours.”

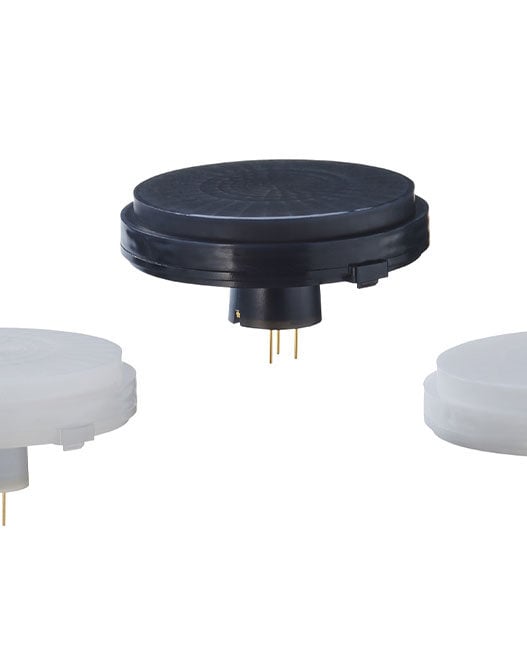

Credit: Georgia State University

Credit: Georgia State University

The van der Waals semiconductors empowered vertical colour sensor (vdW-Ss) represent a newly-emerged class of materials, in which individual atomic layers are bonded by weak van der Waals forces.

“The ultra-thinness, mechanical flexibility, and chemical stability of these new semiconductor materials allow us to stack them in arbitrary orders. So, we are actually introducing a three-dimensional integration strategy in contrast to the current planar micro-electronics layout. The higher integration density is the main reason why our device architecture can accelerate the downscaling of cameras,” Li says.

The team used synthetic methods to mimic biochemical processes, using nanotechnology.

The technology currently is patent pending with Georgia State’s Office of Technology Transfer & Commercialisation (OTTC). OTTC anticipates this new design will be of high interest to certain industry partners.

“This technology has the potential to overcome some of the key drawbacks seen with current sensors,” says OTTC’s Director, Cliff Michaels. “As nanotechnology advances and devices become more compact, these smaller, highly sensitive colour sensors will be incredibly useful.”

Researchers believe the discovery could even spawn advancements to help the vision-impaired one day.

“This technology is crucial for the development of biomimetic electronic eyes and also other neuromorphic prosthetic devices,” says Li. “High-quality colour sensing and image recognition function may bring new possibilities of colourful item perception for the visually impaired in the future.”

Lei says his team will continue pushing these advanced technologies forward using what they’ve learned from this discovery.

“This is a great step forward, but we are still facing scientific and technical challenges ahead, for example, wafer-scale integration. Commercial image sensors can integrate millions of pixels to deliver high-definition images, but this has not been implemented in our prototype yet,” he says. “This large-scale van der Waals semiconductor device integration is currently a critical challenge to be surmounted by the entire research society. Along with our nationwide collaborators that is where our team is devoting our efforts.”