Processor-based systems at the heart of equipment such as industrial controllers, network equipment and consumer products require power to be applied separately at different voltages and in a specific sequence to the processor core, peripherals, I/Os and memory. In some cases, sequencing may be needed to avoid large in-rush currents on start-up. In other systems, the power-up sequence may be critical to ensure the system initialises properly, or to protect components or sub-systems from damage.

System elements, such as the processor, logic, memory and some peripherals, are often integrated in an SoC device that requires multiple power rails of different voltages to be applied at various pins. Other sub-systems, such as motor drivers, power MOSFETs, IGBTs or communication interfaces such as Ethernet or RS-232/422 serial ports, may also be included. Even small equipment can require 10 or more power rails from independent DC regulators or power converters.

Controlling the power-up sequence

A straightforward sequence may be ensuring supply B is only turned on after supply A has been turned on. A more complicated system may need to turn supply C on only once rails A and B are on. (A supply is usually considered on when the output is at 90% of the final rail voltage, although critical applications may require the rail to be closer to final voltage.) It is easier to accurately measure timing than voltage, so some designs are based on a specific voltage rail reaching the desired value within a defined time.

.jpg) Figure 1: Power supply sequencing using the LM3880 ensures reliable system start-up and prevents excessive inrush currents (Source: TI datasheet)

Figure 1: Power supply sequencing using the LM3880 ensures reliable system start-up and prevents excessive inrush currents (Source: TI datasheet)

Whether determined by timing or voltage level, the period between the successive rails being turned on is usually milliseconds. If a sub-system, such as a heater, must come up to full temperature before the rest of the system starts, or if the system processor must check for a safety signal before turning on power however, that period may be several seconds.

Efficient use of space

If the system contains discrete power converters, each equipped with an enable pin and a power-good output, each power-good can be used to ensure the next converter in the sequence will only start when the preceding rail has reached a level to assert the power-good signal. If one or more of the converters has no enable input, sequencing is achieved by using the turn-on signal to control the gate of a MOSFET placed in series with the output.

If no power-good signal is available, additional circuitry is needed to sample the output voltage of, for example, converter A, to generate an enable signal for converter B. Timing circuitry can provide an alternative to voltage sampling. Both approaches have disadvantages, such as extra complexity, component count and PCB real-estate requirements. At this point, an integrated power sequencing IC or PMIC can be considered.

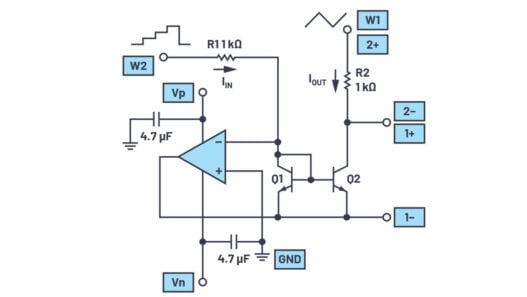

The LM3880 from Texas Instruments is an example of a simple power sequencer that can be used to generate enable signals for up to three converters (see Figure 1). At power-up, the sequencer’s three output flags are held low. The IC has its own enable input, which is connected to an internal comparator, referenced to a voltage of 1.25V. This enables the designer to arrange for the power-up sequence to begin on receipt of a logic signal, or when another power rail or an analogue voltage reaches a certain level. If required, a delay can be added by attaching a capacitor to the enable input. When the enable becomes valid, the first output flag is asserted after a pre-set delay. The same time then elapses before the second flag is set, and again before the third and final flag is set. The time delay is programmed in EPROM at manufacture, and customers can choose from six pre-set timing designators that give delays between two and 120ms. The LM3880 automatically powers-down the rails in the same sequence and with the same time intervals.

.jpg)

Figure 2: The MAX16029 PMIC uses capacitors to program the time delays of four independent channels, and supports DC rails up to 28V (Source: Maxim Integrated datasheet)

The MAX16029 from Maxim Integrated (Figure 2), is a similar four-channel sequencer that enables designers to program the time delay period using external capacitors. Each of the four channels is independent, and each channel output can be used in an open drain configuration, which supports rail voltages up to 28V, as required for higher range DC regulators. Two-channel and three-channel versions are also available, and the company has similar devices that enable the timing to be set via a PMBus interface, rather than capacitors or resistors. This means sequencers can be daisy-chained to handle more than four rails.

Choosing and using a PMIC

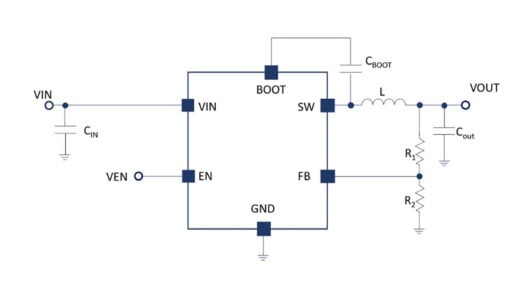

A PMIC containing multiple integrated power supplies can provide a space-efficient, streamlined solution. Be aware that although there may be several linear LDO regulators and switching DC/DC converters combined with features such as protection, diagnostics and battery management, some PMICs are designed for supervisory roles rather than sequencing.

Certain PMICs are tailored to meet the power requirements of a specific device. NXP Semiconductors’ MMPF0100, for example, is designed for systems containing the i.MX6 applications processor. It integrates up to six buck converters, six linear regulators, a real-time clock (RTC) supply and a coin-cell charger to supply each of the i.MX6’s power rails, double data rate (DDR) memory and system peripherals. The designer determines the desired output voltage and start-up sequencing for each of the integrated converters, before ordering one-time programmable (OTP) devices with the required values already programmed.

Figure 3: The TPS65916 embedded power controller manages user-programmed sequences (Source: TI datasheet)

Figure 3: The TPS65916 embedded power controller manages user-programmed sequences (Source: TI datasheet)

An alternative class of general-purpose PMICs provides a selection of linear and switching converters, with opportunities to customise settings, such as output voltages, sequencing and protection thresholds, to define powering systems using a convenient and space-saving integrated device.

TI’s TPS65916 PMIC, for example, integrates five configurable step-down converters to power the core, memory and I/O of various types of processor. These switched mode converters support power saving techniques such as adaptive voltage scaling. The PMIC also contains five LDOs to power low current or low noise domains. Power-up and power-down sequences can be programmed on an OTP basis. Transitions can also be configured between the converters’ sleep and active modes. The device is managed by an embedded power controller that manages fetching and execution of the sequences, as shown in Figure 3.

Programmable power sequencing

If an application has many rails or complicated sequencing requirements, or if turn-on and turn-off sequencing must be precisely managed, greater flexibility is required than is achievable from a basic sequencer or general-purpose PMIC without additional components. For such cases, there is a user-programmed microcontroller or a fully programmable sequencer IC.

(2).jpg)

Figure 4: The PIC16F1XXX family supports flexible power sequencing and timing for many rails. (Source: Microchip Technology datasheet)

A power sequencer using a member of Microchip Technology’s PIC16F1XXX family can handle four, eight or more power sources (see Figure 4). The embedded firmware is user-programmed for desired sequencing attributes, along with power-good criteria, ramp-up time and ramp-down time. It also implements various alarm modes if a supply fails or goes out of range. The PIC-based approach has a 10-bit ADC but digitises each rail 16 times and averages the result, yielding the equivalent of a four-bit conversion. The number of general-purpose I/O (GPIO) pins for enabling a voltage regulator or driving a rail MOSFET can number dozens, and can thus be capable of handling almost any situation.

(2).jpg)

Figure 5: The UCD90120A can sequence and monitor up to 12 rails, with additional supply-related sensing and control options (Source: TI datasheet)

For a sequencing-specific device, UCD90120A from Texas Instruments offers another fully programmable approach (see Figure 5). This 12-rail power supply sequencer and monitor is addressed by a PMBus/I2C interface, and includes 26 GPIO pins that are available for other supply-related functions, such as generating supply enables, resets and alarm interrupts to the system processor. When combined with a suitable graphical user interface (GUI), it can be used to establish complicated power on/power off sequences and timing, and providing insight for system-failure analysis if a brown-out occurs (Figure 6).

.jpg)

Figure 6: The UCD90120A, combined with a GUI establishes multiple sequencing scenarios (Source: TI application note)

When powering up and powering down electronic and electrical systems, correctly sequencing the power rails ensures reliable system performance and prevents component damage by excessive currents or voltages. Increased SoC integration and the use of complex processors and FPGAs with multiple power rails in embedded systems, mean that correct sequencing is becoming increasingly important at the individual chip level.