Stop-Start technology, which turns the engine off when stopped in traffic and restarts it when the

driver releases the brake or engages the gears, is gaining momentum worldwide as a means to

save fuel and reduce emissions. The downside is the increased number of starts over a Stop-Start

vehicle’s life – potentially more than 100 per day – which means a standard car battery may last less

than 18 months.

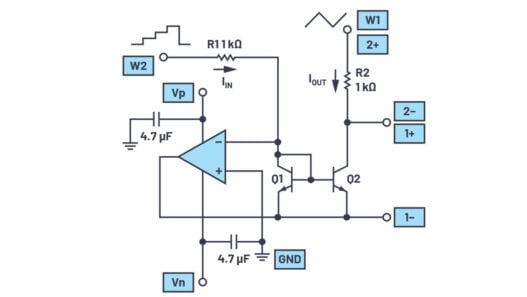

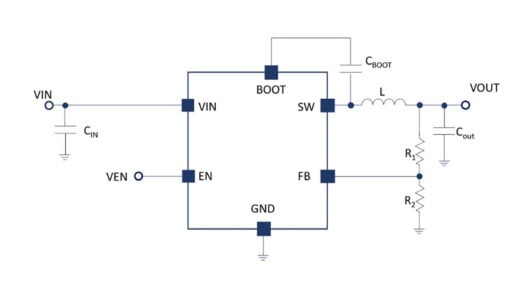

CAP-XX’s prototype Stop-Start supercapacitor module supports the battery by supplying the peak

current (up to 300A) needed for each engine start. Containing six of the company’s thin

supercapacitors, the module is about the size of 6 DVD cases so it integrates easily into a vehicle’s

floorpan, engine bay, or other tight spots. With 150F at 14V, and an ESR of just 4.5 milliohms, the

CAP-XX module offers the best power density available today, and the energy necessary to

support frequent start cycles in all weather and traffic conditions. It includes the control electronics

to manage Stop-Start functions, balance the voltage across each supercapacitor cell, and limit the

battery current during each restart.

With the supercapacitor module installed, the vehicle battery only needs to support continuous

power functions such as air conditioning, navigation and lights, enabling longer battery life or

smaller batteries. The battery also charges the supercapacitors for their first start, but once driving,

the alternator keeps them charged. Additionally, the supercapacitor module will start the engine in

low temperatures (cold cranking) where a battery would falter, and can store energy in vehicles

with regenerative braking systems (also known as Kinetic Energy Recovery Systems or KERS).

In extensive testing under the New European Drive Cycle (NEDC) standard, the CAP-XX

supercapacitor module completed more than 110,000 Stop-Start cycles at room temperature,

successfully maintaining the battery voltage above 11.8 volts. CAP-XX identifies the battery as

having failed when voltage falls below 10 volts because, based on input from a leading European

automaker, batteries at this state of charge can no longer operate vehicle electrical systems

reliably. Comparative tests of a battery-only system, also at room temperature, saw the battery fail

after only 44,000 cycles. NEDC and Mazda Stop-Start test results are available at: CAP-XX

Presentations (slides 3 – 9), while a video showing a similar module starting a car (cold cranking)

can be found at: Subaru Video.

CAP-XX aims to partner with Tier 1 automobile parts suppliers to manufacture the modules, and

will design and prototype the control electronics and modules to suit their requirements. CAP-XX

estimates its module would cost approximately US$60 in mass production, and is already in

negotiations with a leading Chinese automotive component company to commercialize the

technology in China.

“Conventional lead-acid batteries alone cannot satisfy the requirements of Stop-Start systems,”

said Anthony Kongats, CEO of CAP-XX. “Our automotive supercapacitors’ power density is 10 to

100 times greater than that of a lead-acid battery, so they can absorb and discharge large amounts

of energy quickly. With a charge/discharge cycle life in the millions, CAP-XX supercapacitors

provide the energy and power necessary for an efficient and effective Stop-Start system.

Mr Kongats is scheduled to speak on the use of supercapacitors in Stop-Start systems at the EV

Battery Forum in Barcelona, Spain, March 21 – 22, 2012.