3rd order trajectory generation maximises throughput

Optimising the efficiency of motion control systems, an advanced 3rd order look-ahead trajectory generation algorithm has been introduced by ACS Motion Control. The algorithm maximises system throughput, increasing acceleration, smoothness and velocity, while minimising motion induced vibrations and disturbances.

Maximum velocity and acceleration limits for each motion axis are set according to stage parameters, and maximum jerk can be optimised by each user. For further control and optimisation, any of these parameters can be changed during motion. An optimally smooth multi-axis trajectory is constructed by the motion controller through a user-defined path, based on independent axis parameters.

The 3rd order look-ahead trajectory generation algorithm is suitable for smartphone PCB/glass laser cutting via hole laser drilling, LED/OLED inkjet printing, semiconductor wafer scribing, precision conformal coating, precision automated fluid dispensing and precision additive/3D printing. The algorithm is compatible with all ACS Motion Control products.

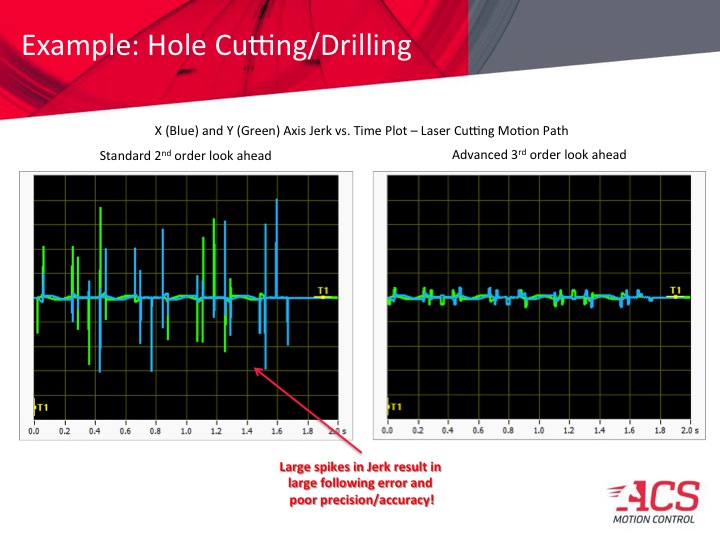

“A 2nd order look-ahead trajectory generation algorithm, which only places limits on velocity and acceleration, can result in significant jerk and vibration in the system, reducing the throughput of the equipment. The more advanced 3rd order look-ahead trajectory generation, which limits jerk, provides much smoother motion and reduces vibration,” commented Jason Goerges, General Manager, ACS Motion Control.