TiHive, an industrial deeptech company specialising in real-time, non-destructive, see-through quality and process control on production lines, has raised €8 million from Karista, Wind, and the EIC Fund to accelerate its growth and expand internationally.

Already adopted by several major industrial groups, TiHive’s technology – which combines industrial-grade silicon-based terahertz imaging devices and artificial intelligence to enable real-time, non-destructive quality and process inspections directly on production lines – is now scaling globally.

This new round of funding will support the commercialisation of its patented industrial vision solutions, reinforce international deployment, particularly in hygiene, textiles, recycling, agriculture, and space industries, and accelerate R&D to develop a new generation of terahertz chips with extended frequencies and advanced AI features.

Backed by industrial and deeptech investors

Backed by support from the EIC Accelerator and Bpifrance, TiHive developed breakthrough Terahertz and AI-based inspection solutions – tested & validated by global leaders in the hygiene sector – and demonstrated strong industrial ROI. The company is now entering a new phase of international commercialisation with a consortium of recognised deeptech and industrial investors.

The EIC Fund, TiHive’s long-standing partner, is joined by Karista, a deeptech hardware specialist, and Wind, a €130 million article 9 fund focused on climate adaptation solutions.

“With this funding, we’ll bring TiHive’s technology to more hygiene production lines worldwide and expand into new markets. Our goal is clear: qualify billions of products annually, helping manufacturers deliver best quality to their customers, reduce costs and save resources at scale.” explains Hani Sherry, Founder & CEO of TiHive.

Absorbent Hygiene Industry: toward more sustainable and efficient production

Traditional solutions rely on sampling-based destructive methods to control quality and assess process stability. A pioneer in deploying industrial-grade terahertz systems at industrial scale, TiHive is reshaping quality and process inspection with its unique Terahertz-AI see-through solution that inspects all production in real-time and non-destructively.

“Too many products still ship unchecked, leading to dissatisfied customers, waste, inefficiencies, and avoidable costs. TiHive addresses this with terahertz-AI products and end-to-end support that integrate into existing processes and remain engaged until KPIs are achieved. Enabling better product quality, trust and reducing operational costs” said Hani Sherry, Founder & CEO of TiHive.

AI-powered, chip-scale technology

The systems are integrated directly on production lines and connected to the machines and to the cloud, measuring the quality and the process stability of thousands of products every minute.

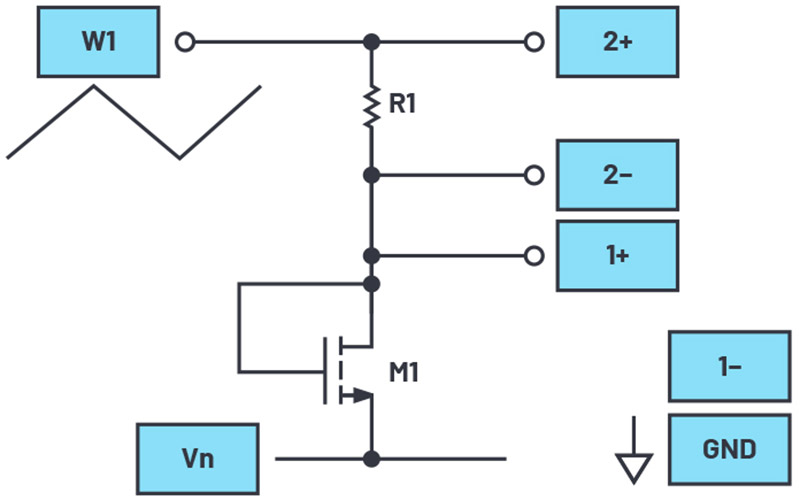

Its technology relies on proprietary semiconductor chips capable of generating and detecting terahertz waves at very high speed (CMOS), paired with advanced THz optics and an AI-powered software platform. Terahertz waves are a safe part of the electromagnetic spectrum, offering see-through sensing and imaging capabilities that unlock a wide range of applications – from industrial quality control (hygiene, packaging, recycling, agriculture, textiles, ceramics, aerospace) to medical imaging and sensing, as well as ultra-fast and secure communications. By integrating terahertz technology on CMOS chips, TiHive enables miniaturisation, scalable mass production, low energy consumption, and high-speed performance.

TiHive has already commercialised its multi-camera, multi-source systems designed to run at high speed in harsh industrial environments, enabling 100% inline, non-destructive inspection of every product. It’s safe, innovative technology addresses industrial use cases that remain out of reach for existing inspection solutions.

Reducing waste and production downtime, improving product quality

Adopted by several leaders in the hygiene sector, TiHive’s vision systems help reduce raw material overdosing, improve product quality, increase production lines efficiency, lower waste, and deliver significant economic and ecological savings.

- A single equipped production line of absorbent hygiene products can save up to 300 tons of super-absorbent polymers per year – the equivalent of 1,500 tons of CO₂ emissions avoided.

The company has also built the world’s largest database dedicated to baby and adult diaper quality, analysing millions of products every week, with the billion-product milestone expected following this funding round.

TiHive’s technology not only boosts industrial performance, but it also enhances the quality of everyday products like baby diapers and sanitary pads, while helping manufacturers reduce production costs and maximise machine uptime by detecting faults as soon as they happen.

A multi-market strategy for industrial quality control

After proving itself in absorbent hygiene industry, TiHive is now targeting new markets where non-destructive control is critical, against a backdrop of growing regulatory pressure:

- Textiles and leather: ensuring fibre and material quality, from technical fabrics to luxury goods.

- Recycling: detecting impurities and analysing raw materials-purity, essential for reuse.

- Agriculture: quality inspection for seeds and crops during growth and after harvest.

- Aerospace and space: non-destructive verification of critical materials on earth or in Orbit.

“TiHive’s silicon and AI platform technology can easily adapt to diverse non-destructive inspection needs and quickly deliver value across industries, from hygiene and textiles to agriculture and aerospace. Our deep tech is also opening space applications, including situational awareness (SSA) & debris detection, and in the future, fast communications (6G), thanks to its form factor, energy efficiency and versatility.” Added Carlos Prada Co-founder and CIO of TiHive

TiHive’s business model is built on an annual subscription that bundles equipment access with AI-powered analytics, monitoring services, and operational support.

Global ambition with a European industrial footprint

With deployments already in the Netherlands, the United States, Italy, and Greece, TiHive is expanding commercially with strong ambitions across Europe, Latin America, and Asia-Pacific. The company is also scaling its operations, with new hires planned in sales and marketing, customer support, as well as Teraherz IC and AI product development.

Staying true to its European industrial roots, TiHive produces, assembles and validates its systems in Europe, in line with its commitment to strengthening the continent’s technological sovereignty.