From its inception in the late seventies, Ericsson Power Modules’ product design and manufacturing processes have been based on clean design principles. It developed the industry’s first products that contributed to reduce energy consumption and environmental impact. This award represents recognition for all the years of investment. Similarly, it is tangible evidence of Ericsson’s commitment, be it a single power module or broadband infrastructure in general, to deliver products and solutions that will contribute to sustainable development, said Elaine Weidman, Vice President of Sustainability and Corporate Responsibility at Ericsson.

Ericsson Power Modules’ initiatives suggest an organization-wide understanding, involvement and commitment in making their products more environment friendly. Different steps that the company took, such as the 3E product development approach and the quality assurance programs for product development, supply chain management and support activities, seems to have fit coherently with the broader objectives of their initiatives, resulting in more efficient and greener products. Said Dinkar Krishnan, Research Analyst – Energy & Power Systems at Frost & Sullivan,

Energy use in industrial, commercial, and residential sectors has been increasing across the world. Along with the increase in demand, energy costs are also rising as supply levels have not witnessed corresponding growth.

Ericsson has identified these global concerns as its own challenges and set a carbon footprint reduction target in 2008 to reduce emissions relative to products sold by 40 percent over five years, from in-house activities and the life-cycle impacts of products. To reach the target, philosophies minimizing the environmental impact such as Clean Design principles and Design for Environment are key. Rising energy demands and environmental concerns are driving the demand for energy efficient and environmentally sustainable products, and Ericsson Power Modules has demonstrated its commitment and capacity to deliver such products to the market.

The Design for Environment (DfE) approach focuses on minimizing the environmental impact of the products throughout their entire life cycle, with a particular emphasis on energy efficiency during the operational phase.

The DfE principle has three top priorities, which include manufacturing, materials innovation, and disposal/recyclable. The first priority includes ways in which new methods of making products are devised, which can help reduce the amount of energy needed for the entire production operation. It also intends to make the processes non- toxic with minimal emissions and least amount of wastages. The second priority considers methods for using materials that have the least harmful impact on the environment and that are easy to recycle. The third priority looks at the easiness of the recycling of a product while it is in the design and packaging stages. This will help the company avoid certain type of materials that are harmful for the environment, while adopting certain other materials such as the recyclable thermoplastics or cardboard packaging.

Another set of goals of the Clean Design principle is to achieve low energy consumption at system level contributing to reduce environmental impact and total cost of ownership.

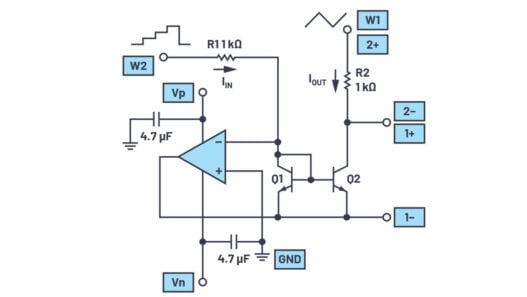

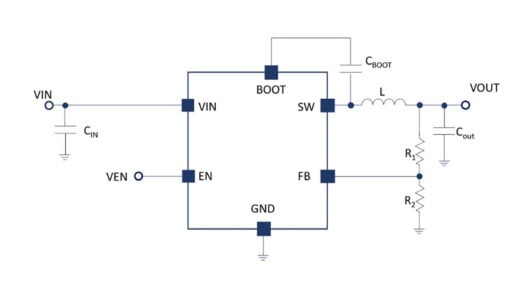

Ericsson Power Modules’ DfE policy drives the design and development of highly efficient DC-DC converters that decrease the energy consumption of end-user equipment by delivering efficiencies as high as 96.0 percent. High efficiencies power-modules combined with new technologies such as digital power control and management significantly reduce energy consumption helping to reduce energy bills, along with reducing the total cost of ownership and the environmental impact. To pure power-technology solutions, other best practices developed at Ericsson Power Modules contributed to reduce environmental impact.

To cite an example, Ericsson Power Modules created the first MacroDens series of DC-DC Power Modules in 1993.

MacroDens was a highly integrated DC-DC converter module with high levels of energy efficiency as high as 93 percent and high reliability levels with mean time between failures (MTBF) as high as over 10 million hours. It was based on thick-film technology and was, manufactured using over-molded ceramics substrate. Lead-free solders were used from the beginning, which demonstrates Ericsson Power Modules’ vision of environmental concerns at such early years. Since 2006, Ericsson Power Modules switched to a Clean Design-based MacroDens, which has migrated from ceramics to halogen-free printed circuit boards. Ericsson Power Modules ensured that less energy is consumed during assembly and the company was able to reduce the mass of the module by about 50 percent to about 10 to 20 grams. The products have been redesigned for easiness of recycling, when they near end-of-life. The redesigned MacroDens products comply with the Restriction of Hazardous Substance (RoHS) directives as well.