Embedded edge computing: requirements have increased

Today, embedded computers are often deployed as edge computers. This is not just a buzzword but the answer to increased demands for IIoT-connected devices, machines and systems. Intel and congatec are addressing these new challenges with an extended ecosystem that is strongly geared towards concrete solutions and goes far beyond core processor functions.

By Andreas Bergbauer is Product Line Manager for COM Express at congatec

Intel’s high-end mobile and embedded processors – whose 14nm++ microarchitecture was developed under the codename Coffee Lake H Refresh, and which have recently become available in multiple new variants from Intel Celeron to Intel Core and Intel Xeon processors – will often have to perform much more advanced tasks than their predecessors. In line with the Industry 4.0 trend, IIoT-connected devices, machines and systems are subject to significantly higher, sometimes extremely heterogeneous requirements.

Increased demands on real-time systems

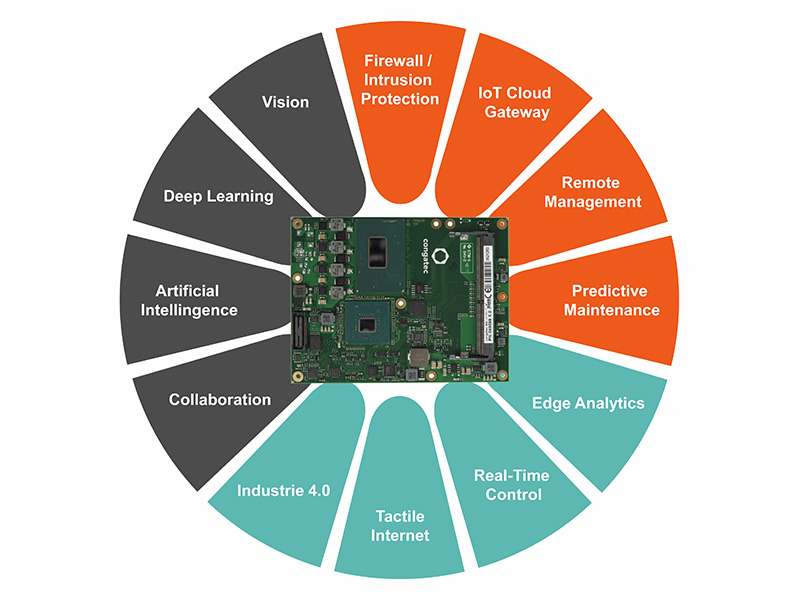

Today, there is a growing need for classic real-time controllers to be connected via Industry 4.0 protocols such as MQTT, CoAP or OPC UA in combination with standard Ethernet-based time synchronised networking (TSN). The goal is to create a platform-independent, service-oriented architecture (SOA) for tactile Internet to connect smart I/Os, controllers (e.g. PLCs), HMIs and loggers in the field, as well as SCADA, cloud and ERP/MES systems with each other in real time.

Significant rise in security demands

The high network connectivity this requires opens security risks, which leads to the need to integrate more security functions. Examples are a unique tamper-proof identity for authenticating each device; implementing secure authentication and sharing credentials between the embedded system and the network; ensuring proper device functionality by validating installed software and updates; using cryptography for all network communications; and protecting stored information.

Not to forget software-defined networking functions such as intrusion prevention and detection systems, which analyse data traffic in parallel to the applications and thereby avoid latencies that would arise with serial analytics and applications.

Higher need for edge analytics and IoT connectivity

In addition, there is also growing demand for manufacturer-specific data analysis at the edge of devices, machines and systems for new predictive maintenance and subscription-based pay-per-use services. This is because it makes more sense to take decisions locally. Only the most important data such as status and alarm messages are transmitted.

If the local analytics requires image data for AI, bundling high computing power and processor integrated graphics with the Intel distribution of the OpenVINO toolkit provides a convenient solution. It can be used to efficiently implement smart biometric functions such as face and gesture recognition, which are finding their way into many retail, traffic monitoring, smart city as well as industrial machine applications.

Once edge analysis is in place, the next thing required for data exchange are suitable IoT gateways – e.g. configurable for 3G/4G/5G or LPWANs such as LoRa, NB IoT or Sigfox (aka 0G) – in order to send alarms to central clouds, or to connect the systems to agile subscription management and billing systems such as Zuora.

In the smart robotics field, the increased AI performance of the new Intel platforms and the situational awareness this enables are, for instance, used to implement collaborative robotic applications. These often also utilise dedicated general purpose GPUs such as those from Nvidia (Cuda) or AMD (OpenCL), which are predestined for parallel data processing in image analysis.

Multiple heterogeneous tasks performed in parallel in one system

The desired solution provides all these functions in a single embedded edge computing system. And since real-time communication via Ethernet also works via virtual machines, OEMs are only too delighted when several interactive controllers can be combined on one hardware platform as this reduces hardware costs because only one platform is needed to control several autonomous, increasingly collaborative or even cooperative robots.

With edge computing, embedded system development has clearly become much more complex than it was just a few years ago, when stand-alone, largely autarkic systems were prevalent.

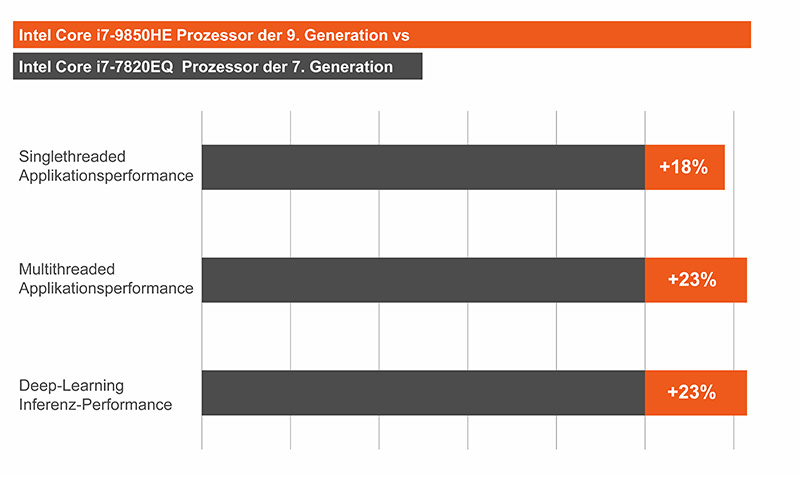

Enormous performance boost thanks to new Intel processors

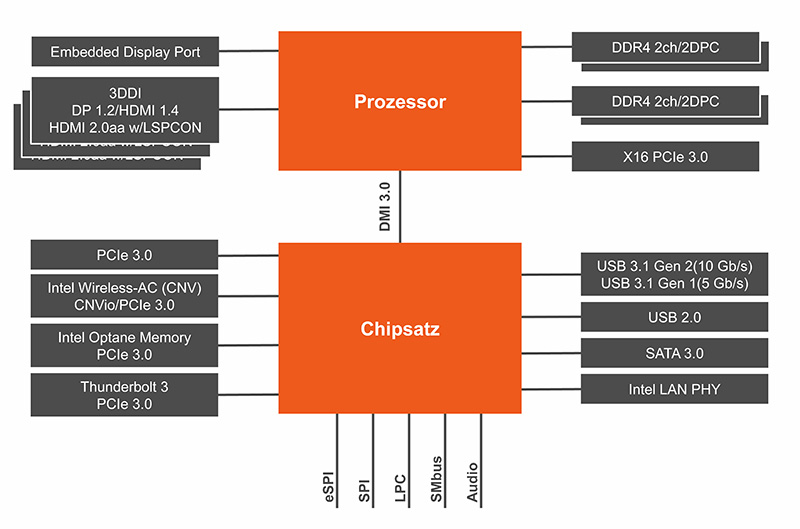

In view of all these heterogeneous requirements, it is very welcome that the new Intel microarchitecture offers a significant performance leap for a given TDP. The spearhead in terms of computing power is the 2.8GHz 6-core Intel Xeon E-2276ME processor with a TDP of 45W.

It offers the highest embedded computing performance with integrated high-performance graphics currently available. When coupled with Intel Optane memory technology, you get extremely powerful embedded systems that feature ultra-fast boot and app startup while also saving a lot of time when storing large files.

The six-core Intel Xeon E-2276ML and Intel Core i7-9850HL processors, which offer a TDP of only 25W, also deserve a special mention. They enable developers to design completely passively cooled embedded edge computing systems that can run up to 12 stand-alone virtual machines in parallel thanks to hyperthreading. Since these processors are low power, they can be operated in fanless, fully enclosed systems under the harshest environmental conditions with the highest IP protection classes.

The same applies to the two quad-core Intel Xeon E-2254ML and Intel Core i3-9100HL processors, as well as the Intel Celeron G4932E processor. They, too, all have a low – partly configurable – TDP of 25 watts.

Using hypervisor technology to consolidate edge computing platforms

To be able to implement the various tasks at the edge as cost-effectively as possible, OEM customers use such multicore platforms to consolidate several, previously separately operated systems on a single embedded edge computer. Virtualisation technologies, such as those offered by congatec on the basis of the RTS hypervisor from Real-Time Systems, make this approach particularly efficient.

The fact that Real-Time Systems is owned by congatec means it is easy to scale the solution. After all, the fact that the RTS hypervisor supports all current x86 platforms does not mean that every platform of every embedded computing supplier has been validated and tested together with the hypervisor. The same naturally applies to all other components and functions that OEMs require: Ideally, their interaction should have been tested and validated in advance.

Proven multifunctional capabilities

Numerous proof-of-concepts have recently been implemented in order to demonstrate that the new congatec platforms can manage both the required individual functions and the interaction between the individual elements. For example, congatec has already implemented TSN on its SBCs and carrier boards and presented these solutions, together with the associated Intel IP, at various trade shows. They used an Intel Ethernet controller, which is often standard equipment in embedded designs and a key factor for the promising future prospects of OPC UA communication via TSN based on open standards.

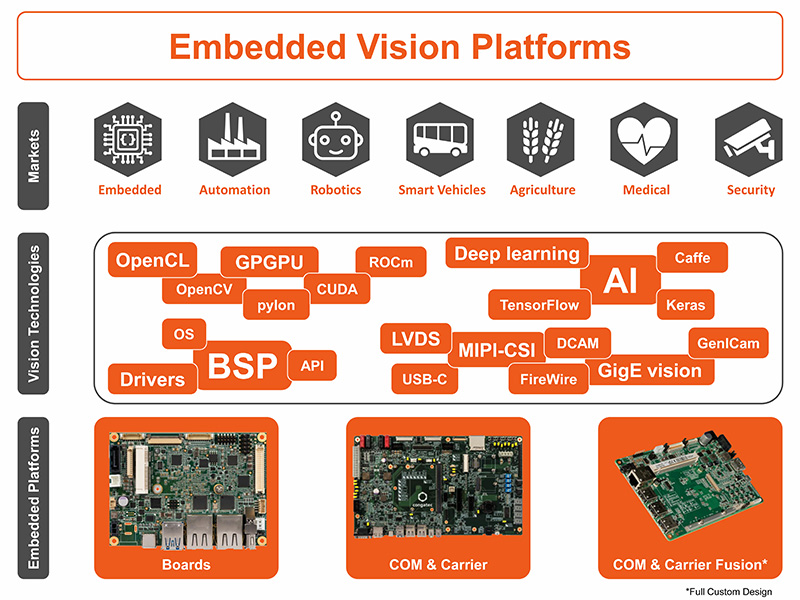

Several embedded vision platforms with integrated AI have further been presented in cooperation with Basler, a company specialising in machine vision. Multifunction platforms that integrate all mentioned functions are already available as an industrial edge computing platform, based on COM Express Type 6 modules with Intel Xeon processors and featuring three application-ready, preconfigured virtual machines. One operates a Basler vision camera where the vision-based object recognition runs on Linux via the Intel OpenVINO software.

The AI algorithms are executed on an Intel Arria 10 FPGA card from Refexces. Two independent real-time partitions run real-time Linux to each balance an inverse pendulum in real-time. With relatively few steps, it is possible to integrate an already existing controller, based for example on Codesys, into such a platform, thereby easily growing it into a powerful edge computing platform that can be expanded with numerous additional functions – including sparse modelling based AI, where only a few images are needed to obtain new inference systems that match the manufacturing task and lighting situation.

This can even be computed on the embedded system itself, since sparse modelling requires significantly less computing power than conventional deep learning. Here, too, congatec has already developed suitable solutions together with Japanese AI provider Hacarus that will soon become available in Europe as well.

Hardware settings tested for real-time capability

Such functionally validated and comprehensively tested demo platforms can be an important foundation for own developments. Suitable in-house long-term tests of real-time behaviour, which can also be provided by OSADL and validated externally, are standard, so that OEMs can obtain validated real-time configurations of the platforms without having to invest any engineering effort themselves.

While the interaction with the application itself still needs to be validated, errors in hardware settings can be effectively excluded from the outset. Such special configurations and corresponding tests are becoming increasingly important because processor-integrated thermal management is partly at odds with deterministic real-time behaviour. If the documentation of the real-time design is already part of the standard delivery, OEMs don’t have to deal with these hardware configuration details.

Remote management system for edge computers

For distributed systems, comprehensive reliability, availability and serviceability (RAS) functions are also important. They can be implemented with specific board management controllers (BMCs) to enable out-of-service/out-of-band system access for edge devices. This will ultimately enable the implementation of highly efficient remote monitoring, management and maintenance functions, similar to those found in commercial data centres, to optimise the total cost of ownership (TCO) of distributed devices. However, all this must also be designed to suit harsh environments.

In addition to the processor-integrated functions from Intel – such as Intel Active Management Technology for out-of-band management – congatec also offers dedicated BMC implementations for carrier boards next to its Computer-on-Modules. On the processor side, congatec opted for the AST2500 BMC from ASPEED, which is based on an 800 MHz ARM11 processor, supports DDR4 1600Mbps and provides on-chip PCIe 2D VGA for the management console.

Using embedded APIs for the IoT

congatec has optimised the BMC firmware to meet the requirements of embedded edge computer management. This includes the possibility to use the embedded APIs of the COM Express Type 6 standard to implement all necessary event logs and alerts into the remote management system. In addition, IPMI chassis power control commands, KVM and media redirection capabilities have been implemented to support both locally connected server consoles and remote KVM. A host debugging console and output switching between the different targets of the host system complete version 1.0 of this release.

To ensure that all this runs smoothly, the new COMs also support Intel Software Guard Extensions (SGX) 1.0, Intel Trusted Execution Engine 3.0, and Intel Platform Trust Technology. Suitable carrier board implementations of TPM modules are also provided on demand to enable comprehensive support of all important security functions.

Computer-on-Modules with integrated edge functions

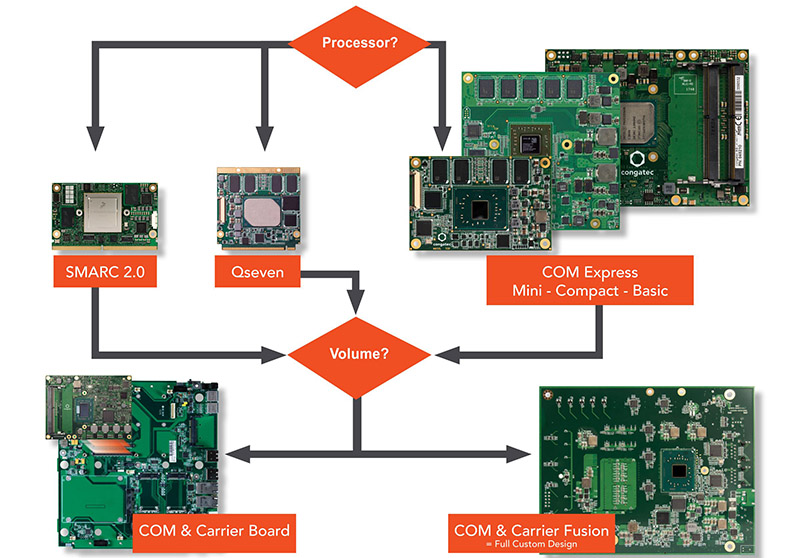

If required, all these heterogeneous edge functions are included in the congatec Computer-on-Modules. They offer far more than the standard advantages of embedded computer boards or modules, such as the ones congatec offers for the new Coffee Lake H Refresh processors based on COM Express Type 6.

However, the extremely high scalability of the modules – of which there are 13 in total – remains interesting to optimally balance application performance as well as closed loop engineering, which makes Intel technology – not only, but also – the platform of choice as an ecosystem for many. And yes, the modules also come as application-ready platforms, which saves developers a lot of time compared to full-custom designs, starting with the BIOS/UEFI and BSP design for all components.

Depending on the application, up to 90% less engineering effort is required if fully developed (evaluation) carrier boards can be brought to series production with a few modifications. It is also no longer a secret that Computer-on-Modules ensure the long-term availability of dedicated applications by making it possible to swap in function-identical new modules when a processor reaches end of life – and thanks to progress in processor technology, these new modules usually consume less power and cost less.

But on the whole, it is evident that an embedded computing platform that is to be used at the edge – which will almost invariably be the case in the future – must offer much more than this.

Beyond application-readiness

Much of the action is happening in software support, including the matching carrier board designs. Virtual machines, TSN-based real-time OPC UA, security and hardware-based root-of-trust, server-level remote management, video and general edge analytics with AI: All this requires many new features that embedded edge computers must support beyond their inherent computing performance, beyond interfaces, and beyond OS support.

So it is good that embedded computing suppliers such as congatec take care of exactly all these hardware-related tasks – without drifting into cloud-related areas, for which there are dedicated IT and cloud specialists who are usually better than some extended workbenches of other embedded computing suppliers. Concentrating on core competencies is the order of the day here, too.

This way, application developers working for OEMs benefit from customised solution platforms where all new IIoT-driven edge functions – which are quickly becoming the norm for industrial embedded edge computers – can be obtained from a single source.

It is the only solution allowing them to fully concentrate on the development of their new applications, without having to struggle with issues that every embedded edge computer should cater for today. Incidentally, management consultancy, technology and outsourcing service providers are increasingly starting to appreciate such application-ready platforms as well. Which goes to show that new business models also create new customer target groups for embedded computer technology.

Available today

conga-TS370 COM Express Type 6 Computer-on-Modules with custom-configured edge functions can now be ordered in 13 standard versions, including individual integration support as well as optional design-in services.

Even full-custom designs with cost-efficient COM and carrier fusion are possible. No matter which solution ultimately fits the application: All solutions are also available with suitable heat spreaders and cooling systems, which OEM customers can obtain from congatec from a single source – even including a standardised heatpipe adapter for fanless cooling of systems with high TDP.