Automotive innovation is rapidly advancing, shifting toward next-generation vehicles that are not only greener, more efficient and higher performing but also safer and more reliable. Much like a human heartbeat, timing components in automotive applications ensure the reliable operation of safety-critical systems. As automotive technology has become ever-more sophisticated and interconnected, with higher levels of performance, deeper and more pervasive integrations, and is just plain smarter, the timing technology that’s helping to synchronise the massive amount of data coursing through these systems must evolve too. Relative to legacy quartz-based timing solutions, microelectromechanical systems (MEMS)–based silicon technology provides superior precision timing, supporting automotive applications so they operate reliably and safely in real-world conditions.

Enhance automotive reliability with MEMS technology

Even as automotive applications advance in what they can do, automotive electronic systems must reliably operate under a wide spectrum of environmental hazards. For instance, they must be able to:

- Sustain shocks and vibrations

- Remain resilient to electromagnetic interference (EMI)

- Start up quickly even at temperatures as low as -40°C

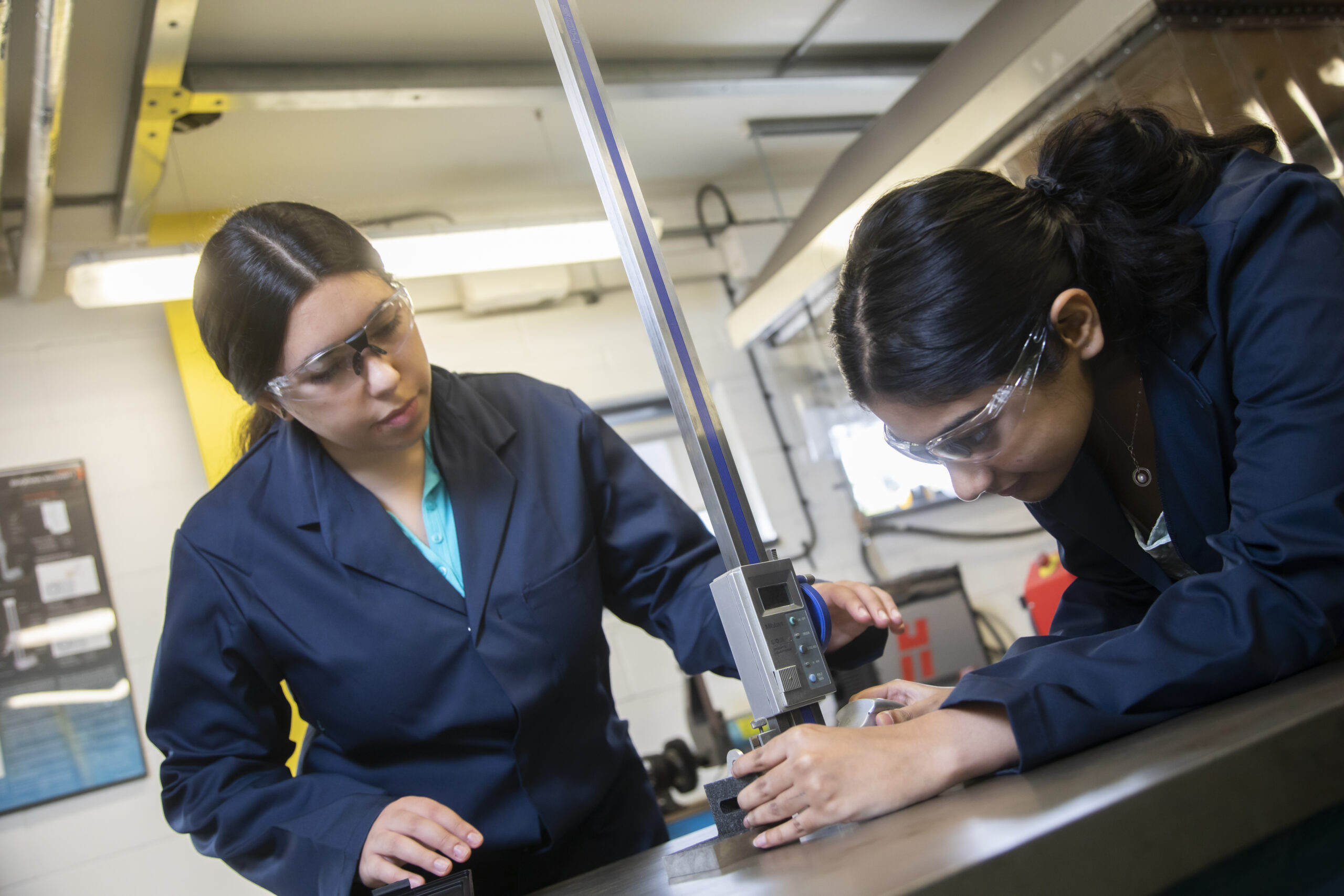

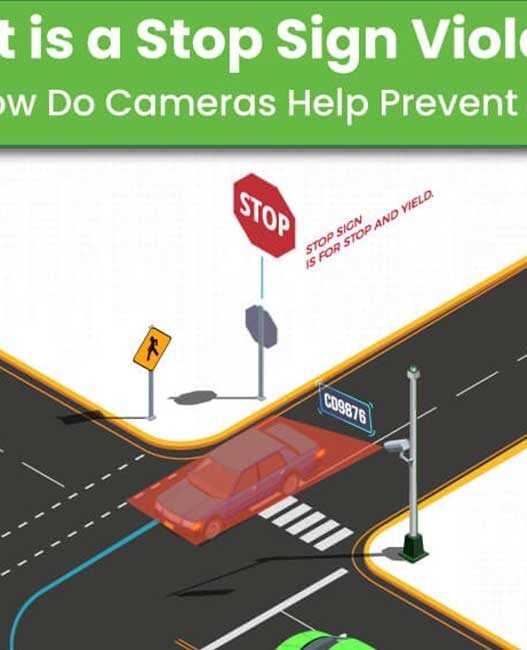

While quartz-based timing components have been in automotive designs for decades, advances in MEMS technology have emerged in recent years to provide a more resilient, reliable alternative to quartz. For instance, the SiTime MEMS-based oscillators consistently outperform quartz counterparts in safety-critical metrics, such as single-point failure rates or latent failure rates. MEMS oscillators consistently meet and exceed the demanding specifications of automotive applications, for example, advanced driver-assistance systems (ADAS), PCIe and SerDes high-speed communications, cameras and sensors. MEMS precision timing also plays a pivotal role in the heart of the vehicle’s electronic control unit (ECU) computer domain controller. Plus, SiTime oscillators have an extremely low failure-in-time (FIT) rate of less than 0.5 compared to quartz FIT rates which can be one to two orders of magnitude higher.

Within our portfolio of precision timing solutions, MEMS oscillators are pivotal to achieving next-generation timing reliability. Made of monocrystalline silicon, SiTime MEMS resonators oscillate only in their fundamental mode. With a size of 200 x 200 μm, they have a 1,000x to 3,000x lower mass than a quartz resonator. Because of their small mass, they are more vibration resistant: An acceleration imposed on the MEMS structure, such as from shock or vibration, will result in much lower force and frequency shift than quartz. Operating in a hermetically sealed environment, the MEMS resonator is central to the SiTime components that support automotive reliability.