Next-generation vehicles will require significant upgrades to traditional vehicle architecture in order to address the major limitations that the automotive industry is facing today, some of which could potentially lead to new business opportunities. Given their different requirements, it is wise to make a distinction between connectivity innovation in the vehicle and off the vehicle.

In-vehicle and off-vehicle software-defined architecture

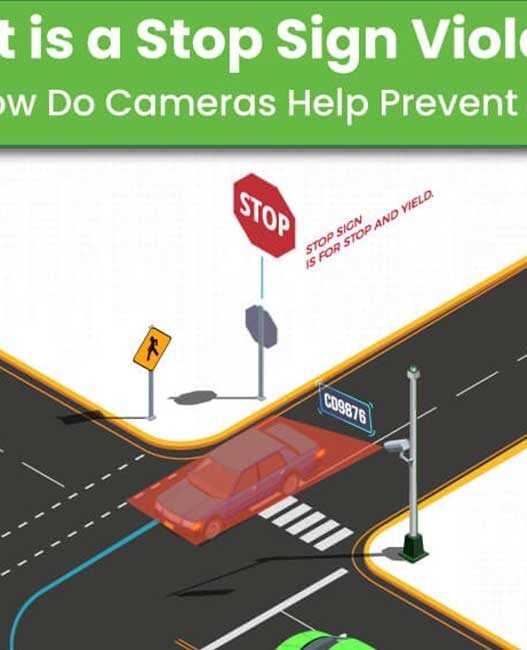

In-vehicle software-defined architectures (Figure 1) will need to be designed to address flexibility, scalability, compatibility and upgradability – and safety needs to be taken into account at each step. Prior to developing a safety-critical system, an architectural analysis must be performed.

The first step will be defining the elements which should be safety certified and consolidating safety domains. Then, creating isolation between safety and non-safety domains, and deciding how the systems are communicating between them. As for the architectural domains, this will not happen at once but rather gradually, given the complexity and cost associated with creating a safety domain. Software defined vehicle architectures will also serve to enable vehicle analytics – including reliable and non-intrusive recording, analysis, and replay of real-time data, messages and events at high data rates and high fidelity. Integrating all of these components in an agile and scalable way will be essential for achieving innovation and success in the automotive industry.

Off the vehicle, the evolution of cellular communications with 5G standards and the evolution of WiFi 6 opens new possibilities in telematics and teleoperations, thus creating new business models for both car makers and network operators. Vehicle-

to-vehicle connectivity based on V2X technologies – both DSRC and C-V2X – can open a new scenario for vehicle communication, both on commercial vehicles as well as trucks. But none of this will be possible unless the communication is secure, interoperable, reliable and scalable. Innovation on teleoperation and V2X protocols will be essential for the success of these new markets.

Technical future mobility challenges

The innovations and requirements for future software-defined architectures do not come risk-free. Autonomous vehicle connectivity can be challenging and risky in several domains due to the technical implications, the changes required in the supply chain and changes to accommodate new business models.

Since they are built from many subsystems, vehicles require full interoperability between components. To provide consistently optimal performances, data must flow correctly, reliably and with extremely low latency. In-house connectivity solutions take extensive time to develop and require technical expertise – developers find these to be complex and expensive. Worse, autonomous vehicle designs must last for years, so automakers must ensure that their systems not only address today’s connectivity challenges, but also anticipate future challenges. They must also track constantly evolving technology and security requirements. In addition, the variety of new and legacy technologies that must interoperate increase the complexity of the overall system.

Above: Figure 1. In-vehicle architecture evolution

In a software domain, the architectures will need to solve the current paradigm based on the heterogeneity of communication hardware interfaces (eg., TSN, CAN, Ethernet, PCIe), embedded systems and platforms (AUTOSAR, ROS 2, RTOS) and safety requirements (ISO 26262, ISO 21434), (Figure 2).

Among these technical challenges, the path to safety has the highest risk and cost associated with it. A successful safety strategy must provide:

- Cost-efficiency, while maintaining the highest standards.

- Flexibility to evolve safety platforms through the platform lifetime.

- The ability to enable unknown safety requirements.

- An easy path to integrate in certified environments.

- The ability to isolate safety data communication from non-safety data, while allowing connectivity.

Together, these challenges make connectivity a risk point. So developers need a reliable, proven solution.

Automotive connectivity framework as a solution

Future mobility challenges can only be overcome through standardised technology that enables developers to optimise their architectural definition, while providing flexibility, scalability and security at the same time.

In development terms, developers must benefit from a level of hardware abstraction, which would in turn allow them to access the optimal component set from any number of different manufacturers. At the same time, this framework must facilitate and provide the flexibility to operate the different functionalities at all development tiers (OEMs, Tier-1s, Tier-2s and third party integrators). All of this in a context of a mixed safety-critical system that can be set in place by the definition of safe and non-safe domains.

In financial terms, the overall communication framework must optimise development and production costs while ensuring that the liabilities and warranties are respected at all times. This will be possible only through close collaboration between all parties, achieved through companies that have a global presence and extensive experience in critical systems.

Above: Figure 2. Software-defined challenge: Future-proof and legacy integration

RTI supplies the communications framework, as well as the corporate structure, to satisfy the needs of the automotive industry. RTI Connext Drive is the first complete automotive grade connectivity solution for autonomous vehicle development. It delivers the automotive connectivity software framework required, from on-vehicle to connected car applications. It accelerates the development and deployment of autonomous vehicles, including safety designs.

RTI Connext Drive is built on the Data Distribution Service (DDS) standard. DDS is the only open standard for connectivity that supports the unique needs of both enterprise and real-time systems. Its open interfaces and advanced integration capabilities slash costs across a system’s lifecycle, from initial development and integration through ongoing maintenance and upgrades. RTI Connext Drive is also the only proven connectivity standard used by AUTOSAR Adaptive and ROS 2 for autonomous vehicles, (Figure 3).

Above: Figure 3. RTI Connext Drive Automotive Framework

Conclusion

For automakers building the vehicles of tomorrow, every decision – from design to prototype to production – needs to be the right one. After all, the agility to move at top speed is vital in the fastpaced world of autonomous vehicle development at every stage of the project. So choosing the right connectivity software at the beginning can help automakers glide gracefully over the finish line.

The characteristics of a reliable Automotive Framework include:

- Proven in-use single framework within an autonomous system: reducing the need for maintainability, as well as long-term technology costs.

- Ability to build a next-generation in-vehicle architecture despite unknown requirements, such as hardware, capability of autonomy and dynamic updates at deployment.

- Low-risk and future-proof: The different product components must be easy to integrate with other parts of the system, and at the same time be compatible with major automotive ecosystems (e.g., ROS 2, AUTOSAR).

- Proven in safety-critical projects.