Making IP as easy as ABC

Technology has made it possible for a single person monitoring a bank of monitors to replace a small army of roving watchmen, aided by IP cameras placed in locations where it would be unsafe or impractical to station a live human being at all. By Susan Stanley, Training Manager, B&B Electronics.

Unlike the old CCTV cameras, IP cameras can report to any desired location, provided that there’s an Internet connection. They also provide two-way communications and the DVR may be located at the central office or in the camera itself. IP video surveillance can cut security costs while simultaneously providing enhanced surveillance capabilities.

But before they can get their data where it needs to go, IP cameras must address a number of challenges. Range is usually a major concern, as IP cameras are used for everything from parking garage security to pipeline monitoring. With a range limitation of just 100m, ordinary copper Ethernet cable will rarely do the job. Harsh environmental conditions present another set of problems. The cameras, their associated equipment and their Ethernet connections must be rugged and resilient enough to function outside of the safe, climate controlled IT closet. The installation will also require a power source and if a heater is needed, or a wiper for the camera lens, it will make provisioning power at a remote location that much more complicated. Finally, after all of the other issues have been addressed, IP cameras will require a lot of bandwidth. Even simple systems call for 100Mbps, High Definition cameras require even more.

The IP camera, of course, is just one node on the network and modern networks may include any mix of copper, wireless and fibre. This calls for media conversion at interfaces between all of the different systems. To keep things manageable, it’s useful to deploy single-box, multi-port devices that can provide multiple conversions for cabling and connected devices. This simplifies network topologies, saves space and reduces the number of possible failure points.

At the same time, as network topologies continue to become more complex, there is an increasing demand for flexible solutions that assign IP addresses to individual cameras, allowing for direct management and monitoring of each camera location using software-based management software systems. End users are demanding centrally located remote monitoring, management and testing tools like SNMP (Simple Network Management Protocol), Remote Network Monitoring (RMON1), and Operations, Administration and Management (OAM). And they’d prefer to get it all in solutions that are easy to install and easy to use.

Options & solutions

With its long range and massive bandwidth, fibre can connect an IP camera virtually anywhere. Copper Ethernet’s 100m range is dwarfed by fibre’s capabilities. Multi-mode fibre provides ranges of up to two kilometres. Single-mode cable can cover 100km. As many IP cameras use Ethernet interfaces, a media converter will be needed to connect to a fibre backhaul, but that’s easy to do and there are numerous single box solutions that will provide both conversion and advanced management tools. Traditional layer 2/3 fibre switches like those from Cisco or Juniper provide SNMP, RMON1 and OAM. But intelligent, multi-port fibre media converters like B&B Electronics’ IE-iMcV-MultiWay provide the necessary troubleshooting capabilities right in the media converter, which simplifies the network and makes them a cost effective alternative.

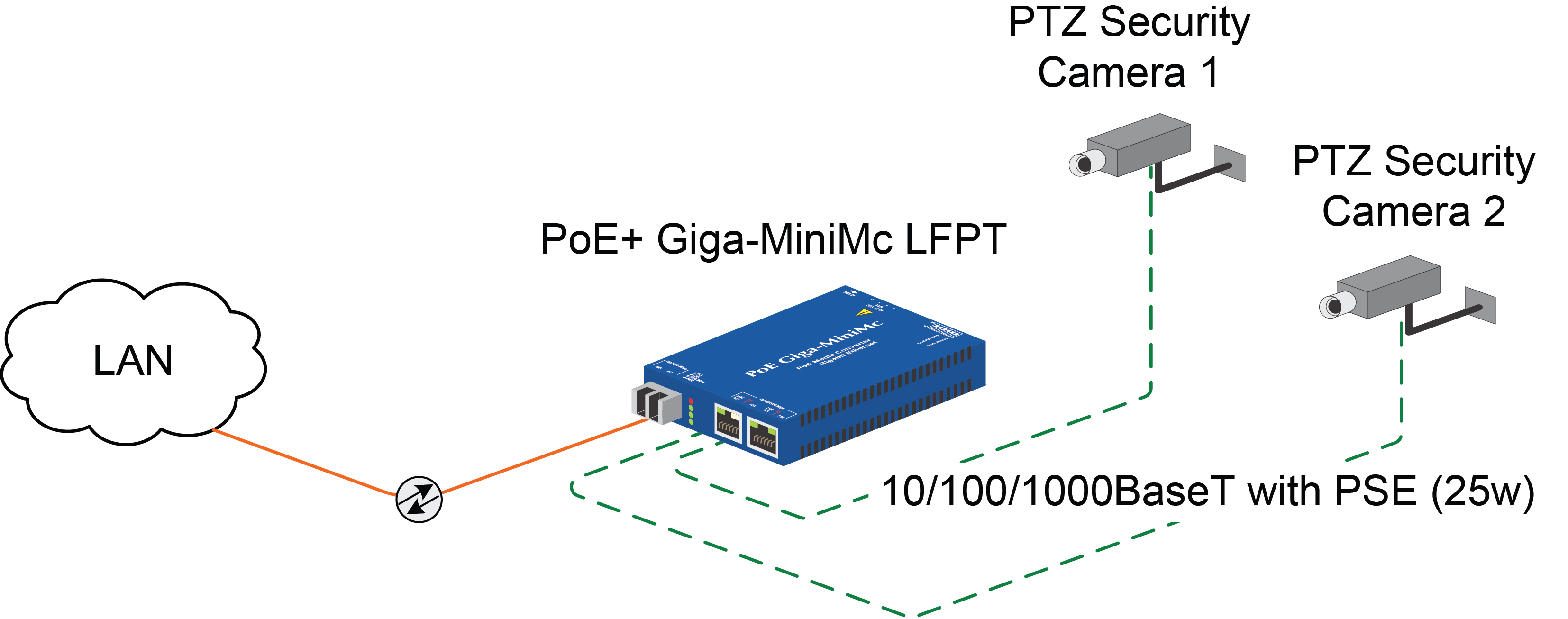

Figure 1 - A typical installation using the PoE+ Giga-MiniMc media converter

IP cameras are typically installed in inconvenient locations. (You’ll see them on top of light poles, for example.) They’ll need a power supply and — as many IP cameras will also have a copper interface — they’ll be connected to a media converter. This is an excellent opportunity to supply power via Power over Ethernet (PoE). PoE fibre equipment like B&B Electronics’ PoE+ Giga-MiniMc media converter (Figure 1) can make the necessary media conversion while using the copper Ethernet connection to provide PoE power to connected devices.

PoE technology lets PSE (Power Source Equipment) devices inject power over an existing copper wire (CAT5 cable or better) concurrently with the Ethernet data stream. It will power IP surveillance cameras (as well as VoIP phones) that lack a nearby power outlet. The 802.3sf and 802.3ag standards for Power over Ethernet ensure compatibility and functionality amongst equipment vendors. PoE will provide up to 15.4W of power to a device and PoE+ will support up to 25.5W. This works because a copper RJ-45 cable has four wires; two support the data stream and the other two are available for PoE. A PoE copper port’s ability to carry power will not impact or reduce the efficacy of the data stream. B&B Electronics’ PoE+ Giga-MiniMc media converter is an unmanaged PoE+ device with two 10/100/1000 copper ports and one fibre SFP (Small Form Pluggable) port. The fibre SFP port allows the user to future-proof the installation, easily facilitating a migration from 100Mbps to Gbit. Multi-port Gbit PoE switches can eliminate the need for a more expensive device at the central office or CPE.

By way of an example, a transportation department in Brazil wanted to upgrade its system with IP video surveillance cameras. The cameras would be placed in outdoor locations, which would expose them to weather and temperature extremes. The central headquarters would need to monitor and manage the cameras at ranges of up to 30 kilometres, and the communications would need to be highly secure. The city had already installed fibre optic infrastructure. This existing fibre could provide the cameras with long range Ethernet connections, but the data from the copper Ethernet ports on the cameras would have to be converted for fibre optic transmission. At the other end of the connection, the central office used chassis-based media converter infrastructure. So the transportation department preferred a chassis installable, DC power solution.

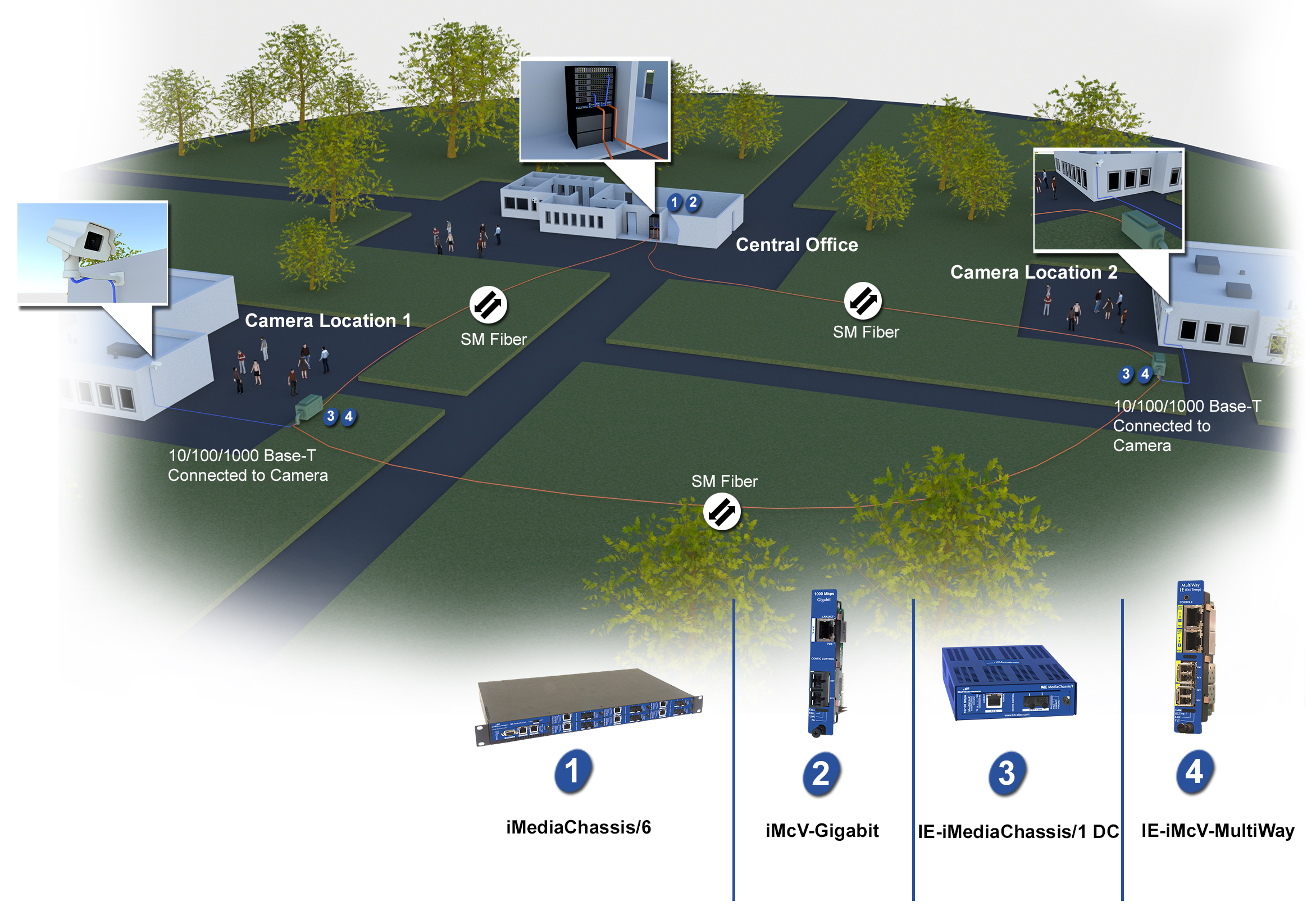

Figure 2 - Real-world installation using fibre and copper

The transportation department installed Gbit copper-to-fibre media converters in an existing six-slot chassis. This connected two central office servers to the fibre optic network. At each of the camera locations the department installed a four-port, IE-iMcV-MultiWay converter with SNMP and rugged temperature specs, Figure 2 shows the topology. To make the installation even more rugged, they used an extended temperature, DC-powered chassis, and housed the chassis and converter in a NEMA enclosure at the base of the pole that elevated the camera. A copper line connected the IP camera at the top of the pole to the IE-iMcV-MultiWay in the NEMA enclosure at the bottom. The IE-iMcV-MultiWay converted the data for transmission to the central office via the fibre optic infrastructure.

In another example, when a successful European toy manufacturer outgrew its facilities it built a brand new campus that included new office, manufacturing and warehouse space. As copper Ethernet cable has a range limitation of around 100 meters, the manufacturer used Multi-mode fibre to network the three new buildings. Multi-mode fibre not only provided the necessary range, it added immunity to Electromagnetic Interference (EMI), speeds of up to 1Gbps and high security. (You can’t hack into a beam of light with your laptop.) As the facility received daily visits from toy sales representatives and other outsiders, security was an important consideration.

The owner also wanted to establish 24/7 video surveillance for the campus. But the outdoor IP cameras had 100Mbps copper interfaces and the campus network infrastructure used fibre. Additionally, most of the IP cameras would need to be installed in locations that were a long way from any power outlets. Standard copper to fibre media converters could convert the signals from the IP cameras, but they wouldn’t solve the power problem. And because the cameras would be outdoors, the company needed equipment with extended temperature specs and the ability to observe and report faults on remote copper and fibre connection.

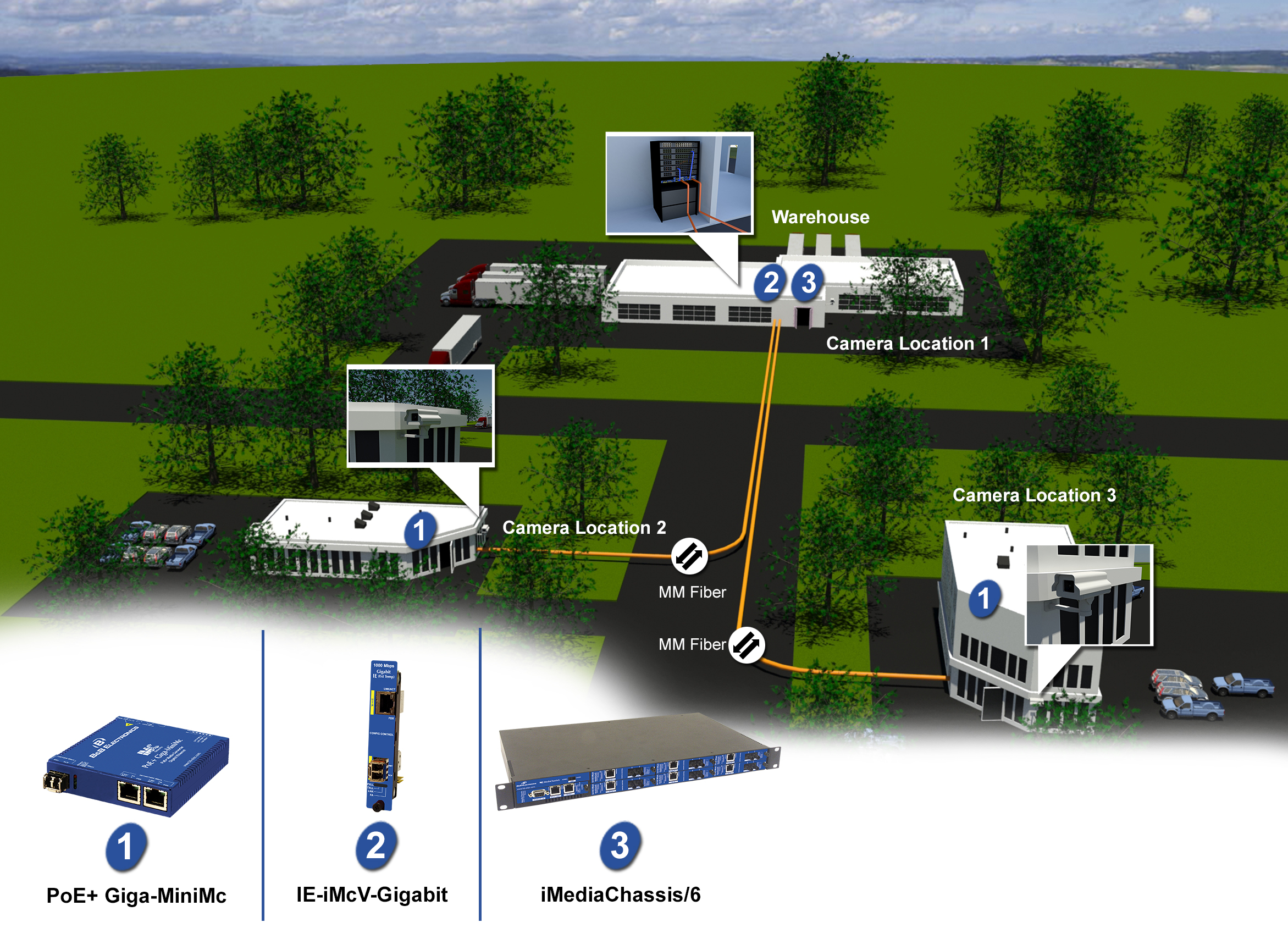

Figure 3 - Linking multiple sites, securely

The manufacturer chose B&B Electronics’ PoE+ Giga-MiniMc with a diagnostic feature called Link Fault Pass Through (LFPT) (Figure 3) The compact converter includes two 10/100/1000Mbps PoE copper ports and an SFP fibre port. While concurrently supporting the Ethernet data stream, each of the Ethernet ports can also inject power (up to 25W) to the remotely connected IP cameras. To prevent damage to connected equipment, the converter will only provide as much power as the equipment actually draws, that eliminated the need to run dedicated power lines out to the camera locations.

The SFP fibre ports support 100 or 1000Mbps, which future-proofs the installation. The factory only requires 100Mbps connectivity to meet its current needs. But if at a later date they wish to upgrade the system to Gbit, the PoE+ Giga-MiniMc with LFPT easily transitions from Multi-mode to Single-mode fibre. The hot-swappable SFP transceiver is the only component that would need to be changed.