Choosing the right dielectric helps you get the behaviour you want from a capacitor. Each dielectric affects how much charge the part can store, how steady that value is, and how it behaves as temperature and voltage change. When choosing a capacitor, it is best to think about the electrical requirement first and then work from there.

What to think about when choosing a dielectric:

- How steady the capacitance stays as temperature and voltage change

- How well the part holds charge over time

- How much internal resistance it has, and whether it gets warm under load

- How well it works at higher frequencies

- Whether its size and voltage rating fit your design

- How the value changes as the part ages

Here, Electronic Specifier has put together a list of five of the most common dielectrics with details on their strengths and limitations, as well as how to match a dielectric to an application.

Ceramic (NP0/C0G)

What it is: a ceramic material that keeps its value steady as conditions change

Pros: very stable, very low loss, works well at high frequency

Cons: only small capacitance values available

Use for: timing circuits, stable filters, high-frequency work

Ceramic (X7R, X5R, Y5V and similar)

What it is: ceramic materials that offer more capacitance in a small size but change with temperature and applied voltage

Pros: high capacitance in compact packages, low cost

Cons: value changes with temperature and voltage, and slowly drifts over time

Use for: general decoupling and smoothing where some value change is acceptable

Film (polyester, polypropylene, PTFE)

What it is: thin plastic films used as the insulating layer

Pros: good stability, low loss, predictable behaviour, and good voltage handling

Cons: larger than ceramics for the same capacitance

Use for: filters, audio coupling, timing, and pulse applications

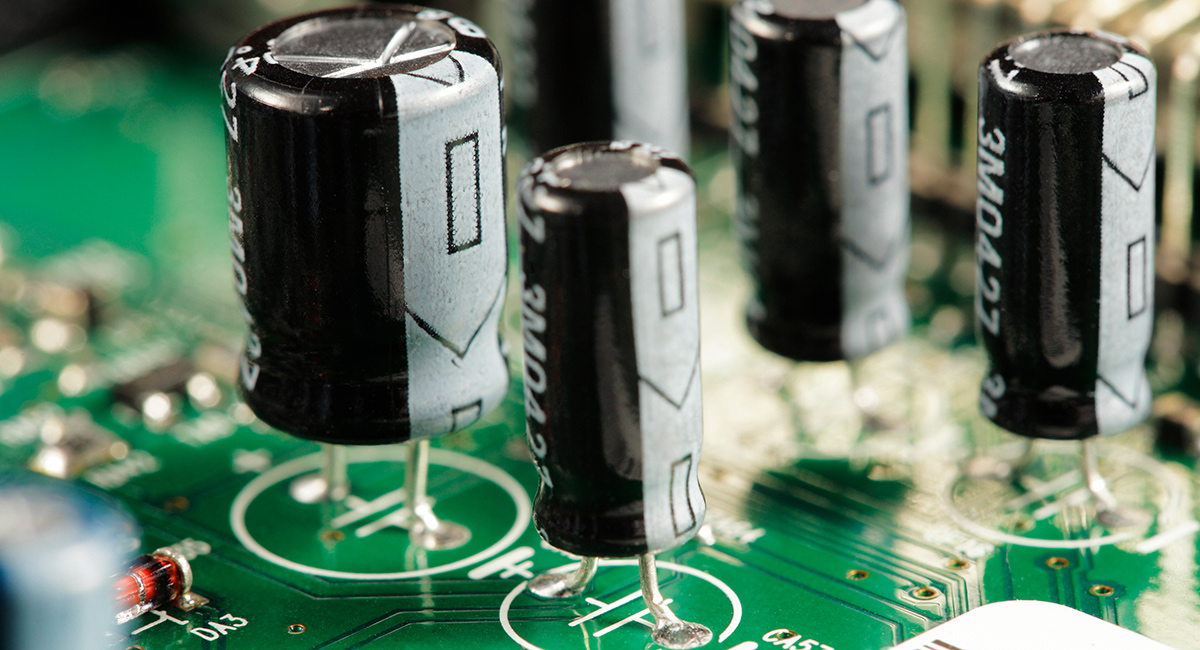

Electrolytic (aluminium, tantalum)

What it is: capacitors that use a very thin oxide layer as the insulating material, allowing high capacitance in small sizes

Pros: very high capacitance for their size

Cons: higher leakage and resistance, limited high-frequency performance, and sensitive to incorrect polarity

Use for: power-supply smoothing and bulk energy storage

Supercapacitor

What it is: a device that stores a large amount of charge for short-term energy use

Pros: extremely high capacitance

Cons: low voltage rating, higher leakage, and not suitable for high-frequency circuits

Use for: backup power and energy buffering

How to match dielectric to your application

For high-speed digital circuits, put a small NP0/C0G close to the pin for fast changes, and use X7R or X5R nearby for larger values.

For power supplies, choose electrolytic capacitors for bulk smoothing, and use film or ceramic parts where you need lower resistance and better high-frequency performance.

For timing and filters, NP0/C0G and film give steady, predictable results.

For radio-frequency work, NP0/C0G remains the most suitable of these common options.

For short-term backup, supercapacitors provide the needed charge.

In short:

- Stable dielectrics – accuracy and low loss

- High‑permittivity ceramics – space-efficient decoupling

- Electrolytics and supercapacitors – bulk energy storage

These five dielectric families cover the majority of everyday capacitor needs. The key is to balance capacitance value, stability, size, and frequency performance against the requirements of your circuit. Once you know you know these details, the right choice usually becomes clear.

If you focus on the electrical requirement first – and not just size or cost – it will ensure the chosen capacitor delivers reliable performance across the lifetime of your design.