Printed sensor technology is holding strong

Printing sensors is one way to make them cheap enough for widespread IoT applications, and Europe is leading the way in developing this technology, Sally Ward-Foxton writes for ES Design magazine.

Printed electronics technology offers a key benefit to pervasive electronic systems since it can be used to cheaply mass produce devices for applications where the cost is still too high to allow widespread adoption, such as disposable labels or ‘smart tags’. Small sensor systems are required for the development of the Internet of Things, in which all objects can be linked to a network; these sensors are ideal candidates for printing. Sensors tend to have a much simpler structure than displays or logic circuits, so the technology barrier against commercialisation isn’t as high as other printed electronics applications.

According to IDTechEx’s report “Printed and Flexible Sensors 2014-2024: Technologies, Players, Forecasts”, the biggest market for printed sensors is currently glucose sensors, but other types, such as image sensors, are emerging rapidly. Printed and flexible sensors already represent a value of $6.3bn in 2013, but IDTechEx forecasts the market for printed sensors will have increased by more than $1bn by 2020. In fact, following last month’s Printed Electronics Europe event in Berlin, it’s clear that Europe has become a centre of excellence for printed sensor technology. Why is Europe able to excel in this high-tech field?

Government funding

A big driving force is European Union funding that is encouraging collaborations between academia and the industry by funding consortium projects. The European Union’s 7th Framework Programme for research, launched in 2007 has a total budget of €55bn for research and innovation, and has supported more than 19,000 projects so far. Here are some examples of printed sensor projects the EU has funded so far.

SIMS, Smart Integrated Miniaturised Sensor Systems, is a current project aiming to develop paper-thin disposable sensor systems including a printed battery and mobile phone interface. These systems are for detecting cholesterol in a blood sample and will include a nano-biosensor, electronics to perform the test and calculate the result, and a communications subsystem. Printing these devices will allow them to be mass-produced inexpensively.

The ROPAS (Roll-to-roll paper sensors) project is aiming to produce roll-to-roll printed sensors on paper for three specific use cases: security tags, smart labels and smart envelopes. The security tag is for boxes being sent through the mail, to tell if they have been opened – opening the box breaks a circuit within the tag. Similarly, the smart envelope tag can transmit its location and status (opened or not) via RF and it includes anti-tamper wires too. The smart label is able to monitor environmental parameters, like temperature for food storage and distribution; it currently includes a printed battery, plus temperature and humidity sensors which will be printed in future versions of the prototypes. There are 11 partners from six countries involved in the project, which completes in April 2015.

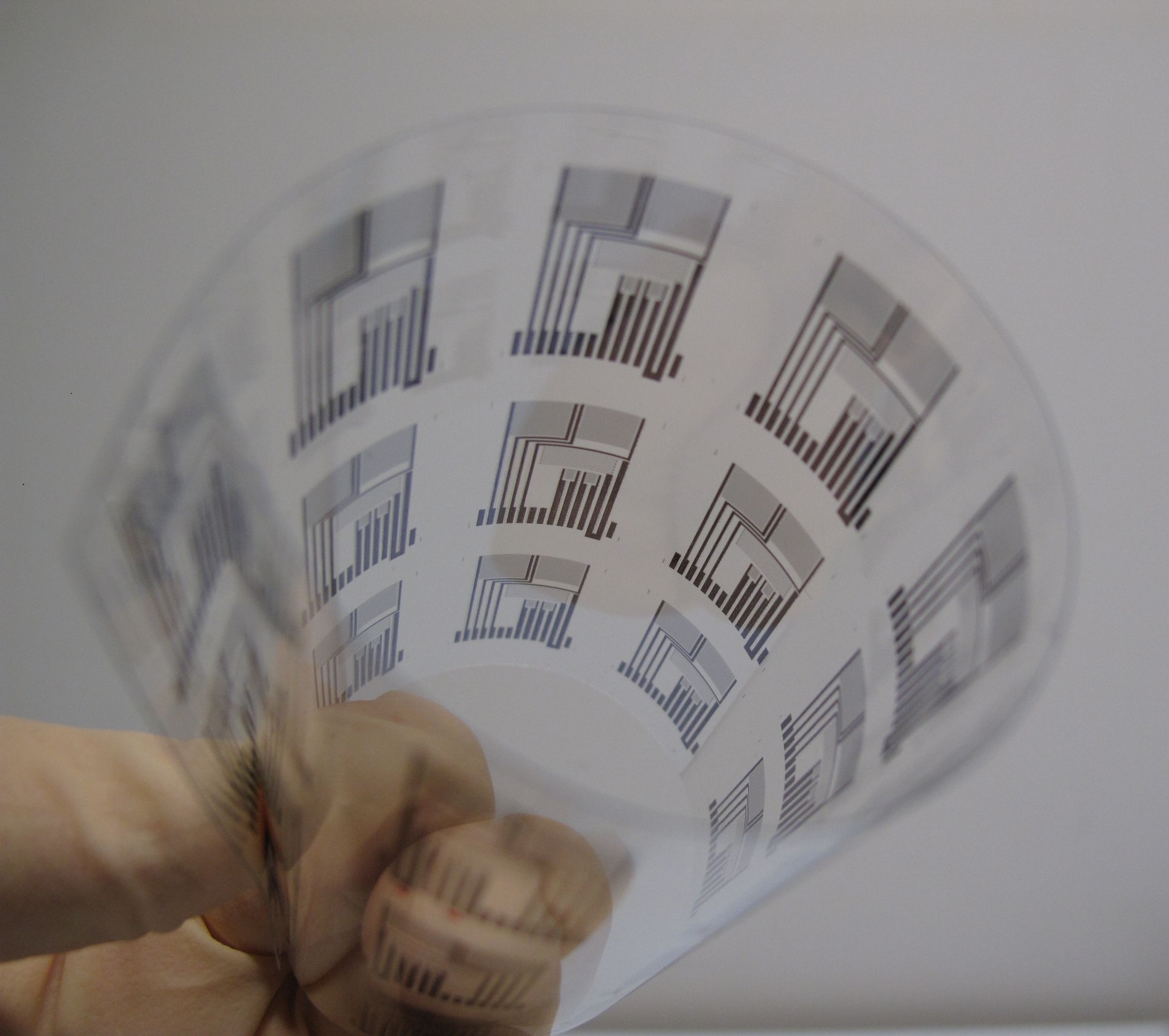

The FlexSmell project’s aim was to develop flexible printed gas sensors using hybrid (organic-inorganic) systems to produce a low-cost, ultra-low-power device. The ‘smell sensor’ is based on bio-receptor technology and is intended for applications including RFID tags. The idea is for the tags to ‘smell’ food freshness as well as providing traceability. One of the project partners, Samlab, developed capacitive gas sensors with an area of 1mm2 on a PET substrate using inkjet printing (see Figure 1). The sensor design also included inkjet-printed/electroplated thermoresistors to compensate for temperature changes during gas sensing measurements. This sensor was integrated with those developed by the other partners into a multi-sensor platform for RFID tags.

Figure 1 - Developed as part of the FlexSmell project is a flexible multi-sensor array fabricated on polymeric foil. The idea is for sensors to ‘smell’ food freshness as well as providing traceability

3PLAST finished in 2011, but it was based on a novel concept combining polymer temperature and pressure sensors with organic electronics on large-area flexible substrates. The basic sensor devices are piezo- and pyrolectric polymer thin-film capacitor-based, while organic thin-film transistors (TFTs) combine to enable signal amplifiers and conditioners. The aim of the project was to integrate printed elements into a working device manufactured by large-area techniques. As for applications, it was envisaged that displays could be triggered by an approaching finger.

European strengths

Aside from financial support, European companies seem to have a particular combination of expertise in the different areas required to develop and commercialise printed sensors based on technology produced by the various research programmes. This includes expertise in organic materials, sensors and semiconductor design, while companies bring together physics, chemistry, electronics and process engineering to produce innovative printed sensor designs and techniques.

For example, France’s ISORG, a spin-out from CEA-LITEN, has developed a printed organic photodetector technology that can be used to build large area image sensors. The company’s most recent demonstrator, a flexible sensor with a 4x4cm active area, was exhibited at FlexTech in Phoenix earlier this year. Built in collaboration with Plastic Logic, the device combines Plastic Logic’s organic TFT backplane with the ISORG printed photodetector array.

ISORG’s technology can be used in a number of different applications, such as consumer electronics displays and imaging products, and those for the industrial segment. Essentially it allows the transformation of plastic or glass into ‘smart surfaces’ that can interact with their environments in a number of ways, like recognising the position of an object, and its movement and shape. Complexity and size of the photodiode array can depend on the product, application and market.

European companies are also good at identifying and capitalising on new applications, such as the much talked-about concept of the Internet of Things. This concept relies heavily on sensor systems at its periphery, feeding information about the environment into the Internet.

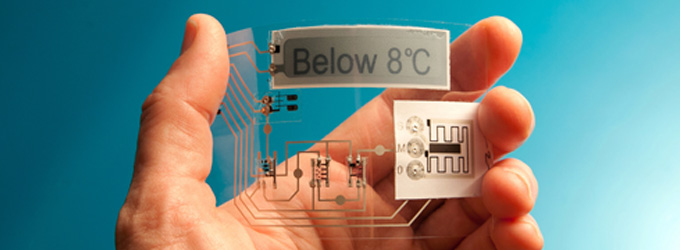

Figure 2 - ThinFilm’s electronic temperature label warns if the ambient temperature goes above a certain level. Target price for this tag is 30 to 50 cents

One company active in this field is Norway’s ThinFilm, working on integrating PST’s fully printed thermistor sensors with its already available printed rewriteable memory and other printed electronics, for intelligent packaging applications. The company has demonstrated an electronic temperature label that warns if the ambient temperature goes above a certain level, intended for food or medicine packaging (see Figure 2). The company’s roll-to-roll printing process is instrumental in producing tags with a target price point of 30-50 cents (compared to around $5 for current systems that do the same job). ThinFilm recently acquired Kovio, the industry’s only printed NFC company with obvious synergies to ThinFilm’s smart sensor and printed electronics expertise.

Display applications

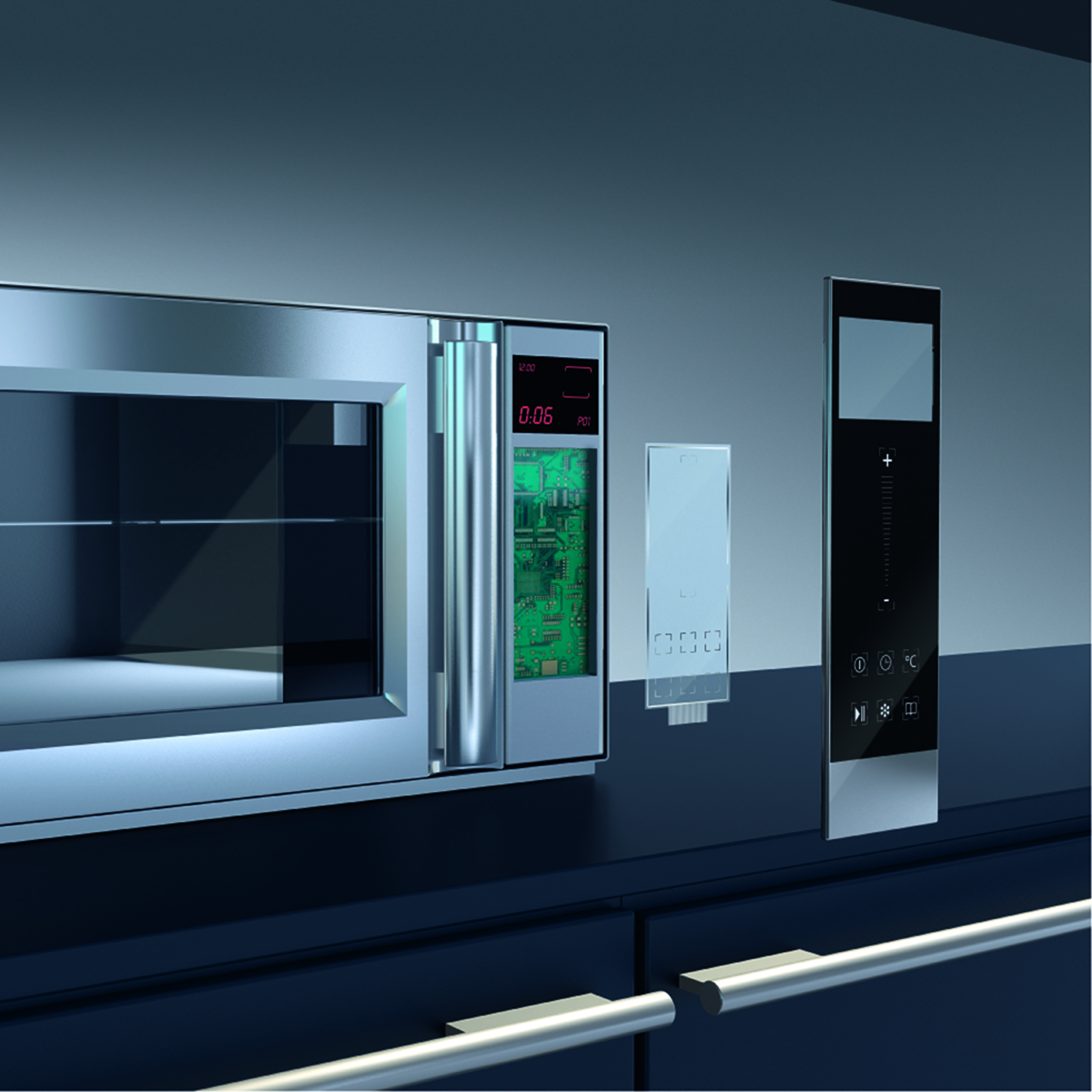

Figure 3 - PolyIC’s PolyTC material can be screen printed onto displays, as a replacement for ITO

Another application targeted by European companies is display sensors. PolyIC, based in Germany, started out as a joint venture between Siemens and Leonard Kurz Stiftung, though it’s now owned wholly by the Kurz Group. This company uses printable polymer conducting and semiconducting materials, printed onto flexible polyester substrates, to build printable electronic devices, including sensor circuits. Conducting polymers can be dissolved to produce electronic ‘ink’ for inkjet printing, to allow for low-cost high-volume production. In terms of printable sensors themselves, PolyIC uses a roll-to-roll printable conductive material called PolyTC to print touch screen sensors for displays. This material is transparent and flexible (it actually exhibits better transparency than ITO) and is therefore ideal for use in display applications (see Figure 3). It can also be used in touch controls for appliances (Figure 4).

Figure 4 - As well as touch screens, PolyTC can also be used for touch controls and buttons

A European company has also seen its printed sensors used in space applications. UK-based Peratech’s printable piezoresistive material, QTC (quantum tunnelling composite) is pressure sensitive and changes its electrical resistance when force is applied. It can be silk-screen printed, but ‘inks’ that can be printed using flexographic processes are under development (Figure 5).

Figure 5 - Peratech’s QTC piezoresistive material can be screen printed, but flexographic printable formulations are under development

QTC is used on the hands of NASA’s Robonaut (Figure 6), a robot that can perform the same tasks as astronauts with equal dexterity when controlled remotely. It’s designed to be used for EVA tasks (extra-vehicular activity; on spacewalks), that is, tasks that were not intended for robots to do. QTC sensors on its hands allow it to get feedback on how tightly it is gripping something, with fingertip sensitivity as good as the human hand. Its features are also robust enough to survive space – for example, there’s no air gap in the sensor, so it can work in a vacuum. The QTC material used on the Robonaut was designed specifically with no start resistance so it draws no power when the hand isn’t gripping something, and so that changes in temperature don’t cause it to expand and contract, which would affect the sensor’s readings.

Figure 6 - Peratech’s QTC sensor material is used on the hands of NASA’s Robonaut, allowing it to get feedback on how tightly it is gripping something, with fingertip sensitivity as good as the human hand

Ultimately, the combination of European Union funding and expertise in physics, chemistry, organic materials, electronics and process engineering is helping to position Europe as a centre of excellence for printed sensor technology. IDTechEx’s report says it expects image sensors to become the second largest market after glucose sensors; piezoresistive sensing is already an established market but will continue to grow, tripling by 2018. The analyst house also said the automotive sector would take a larger share of these products from consumer and healthcare in the coming years.