TorqSense uses tiny piezo-ceramic combs fixed to the transducer’s shaft that distort in proportion to the instantaneous torque level. These create data signals that are transmitted via a non-contact radio frequency coupling rather than by conventional but clumsy slip rings, or high enertia rotary transformers. Because piezo technology requires so little power, this is also supplied via the RF coupling.

This data signal is transmitted to the control unit, from which it can be read on an alpha-numeric display or transferred to a PC for storage and analysis using the TorqView software programme.

“Our larger sensors are used in many applications at the heavy duty end of industry, our smaller ones are used in applications such as fine chemical dosing and lab-based research,” says Tony. “At both ends of this spectrum are applications where splitting the sensing head from the control electronics is desirable. It maybe a space constraint or it may be a matter of protecting the electronics from harsh environmental conditions such as heat, damp, noise, vibration or EMC.

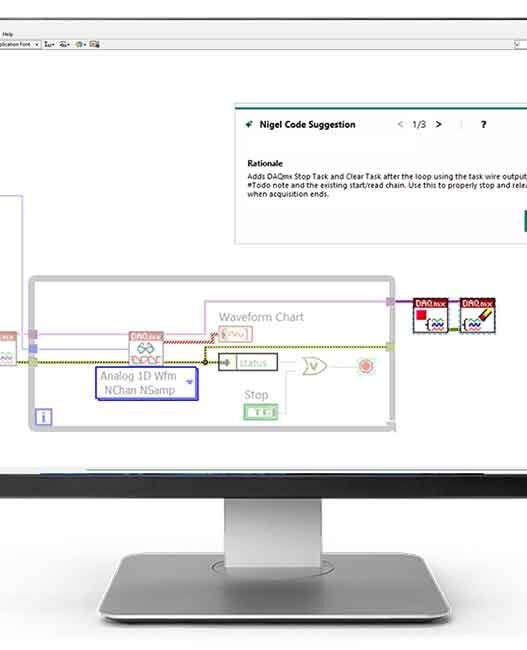

“What TorqSense is about is reliably collecting high speed real-time torque data. With that captured and secure, TorqView can display it via on-screen virtual instruments so users can perform a full range of analysis.