For test engineers responsible for configuring high power semiconductor test systems, the new Model 8020 High Power Interface Panel improves connectivity and simplifies complex measurements like high voltage capacitance-voltage (C-V) measurements. It reduces set-up times, minimises opportunities for connection errors, improves operator and test hardware protection, and increases users’ confidence in the accuracy of their results.

In the past, no standardised solutions for combining high power instruments, interconnects, and probers/test fixtures suitable for all three test types in the same test station were commercially available. When changing from one measurement type to another, high power test system users once had to change the type of cables used manually, as well as critical hardware in the signal path between the device under test and the test instrumentation. High voltage C-V testing was particularly complicated because no standard or reliable measurement setups and methods were established.

The configurable Model 8020 High Power Interface Panel allows test engineers to select the options that match their system’s probe station, positioners, or fixture. It also improves safety for both users and any low power SMU instruments in the system, simplifies incorporating different combinations of instruments, as well as taking the confusion out of adding elements like series resistors and bias tees to the signal path.

It simplifies changing from one measurement type to the next by allowing test engineers to connect all measurement instruments to it at once, making further connection changes unnecessary. When the Model 8020 is configured with optional C-V bias tees on the system’s 3kV and 200V channels, it acts as a high performance I-V/C-V switch, allowing users to perform both I-V and C-V testing without re-cabling.

It provides input connections for Keithley Model 2657A (3kV) and 2651A (50A) High Power SourceMeter SMU instruments, Model 2636B and 2612B SourceMeter SMU instruments, and Model PCT-CVU Multi-frequency C-V Meter. Various user-configurable output connectors are available to accommodate almost any probe station.

The Model PCT-CVU Multi-frequency C-V Meter, which supports C-V measurements from 10kHz to 2MHz, can be used to upgrade any Keithley PCT configuration to include 2- and 3-terminal capacitance measurements. It is designed for use with the new Model CVU-200-KIT bias tee kit to extend the voltage bias to 200V or the Model CVU-3K-KIT bias tee kit to extend it to 3kV to support both AC and DC testing in the Model 8010 or other high power test fixture.

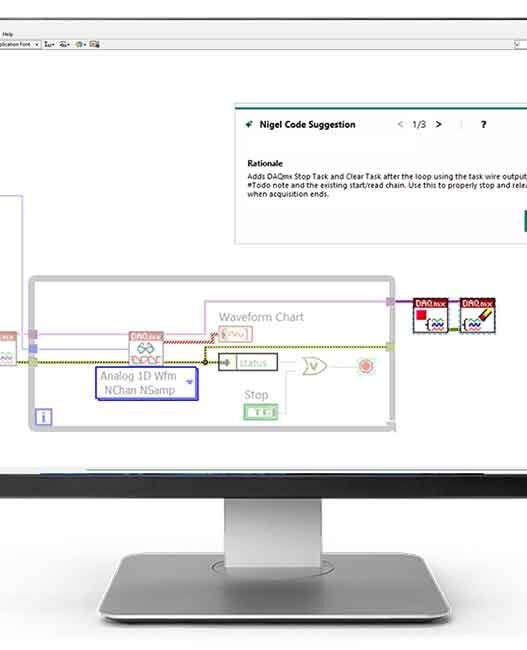

The latest version (V 2.1) of Keithley’s ACS Basic Edition Component Test Software expands the package’s support for I-V and C-V measurements on devices like power MOSFETS, IGBTs, diodes, etc. It complements the advanced C‑V measurements the Model 8020 and new bias tee kits make possible.