As the world becomes more connected, products and services are gaining new levels of intelligence. To enable this digital transformation, semiconductors must also advance. One innovation leading the way is the flexible integrated circuit, or FlexIC, developed by Pragmatic. These circuits offer a low-cost, more sustainable alternative to traditional silicon chips.

Pragmatic’s headquarters is in Cambridge, where the test and validation team work closely with the design group. Manufacturing operations are based in County Durham, Northeast England, at a site known as Pragmatic Park. This facility is home to the UK’s first 300mm wafer fabrication site, with the capacity to house up to nine production lines. Each line is capable of sustainably producing billions of flexible ICs per year.

Flex ICs are ultra-thin and possess a flexible form factor, making it easy to embed intelligence into almost any product. The company’s vision is to empower innovation that bridges the physical and digital worlds, supporting a more sustainable future. As part of this mission, Pragmatic recently launched its third-generation FlexIC platform, which is compatible with standard electronic design automation (EDA) tools. This platform enables anyone to design using Pragmatic’s technology, creating their own FlexICs to solve real-world challenges.

Having been with the company for around 10 years, William Dennett, Senior Test Development Director, Pragmatic Semiconductor recalls joining when the company employed just 25 people. At that time, the test and applications engineering team consisted of only two individuals, and all testing was conducted manually. Since then, the company has seen significant growth. The team now comprises more than 25 people, and Pragmatic employs over 300 staff in total. The test team leads the validation and characterisation of all Pragmatic devices, as well as the development of the production test framework.

Dennett acknowledged the natural challenges of bringing products to market faster and at lower cost and went on to explain the company’s approach to testing in this context. A key strategy is early engagement. By working closely with the design team from the outset, the test team ensures that testability is embedded into chip design. All chips are developed with testing in mind from the ground up.

Wherever possible, Pragmatic reuses existing technology – both hardware and software – to accelerate development. Leveraging established solutions helps reduce time-to-market and streamlines integration across projects.

Another critical factor is maintaining a common platform between the production and development systems. This enables tests developed during validation to be quickly and efficiently deployed onto the production floor. NI’s PXI form factor plays a significant role here. Its compact footprint is well-suited to both the production floor and test labs, while its modularity allows for low-channel-count systems in development and high-channel-count systems in production.

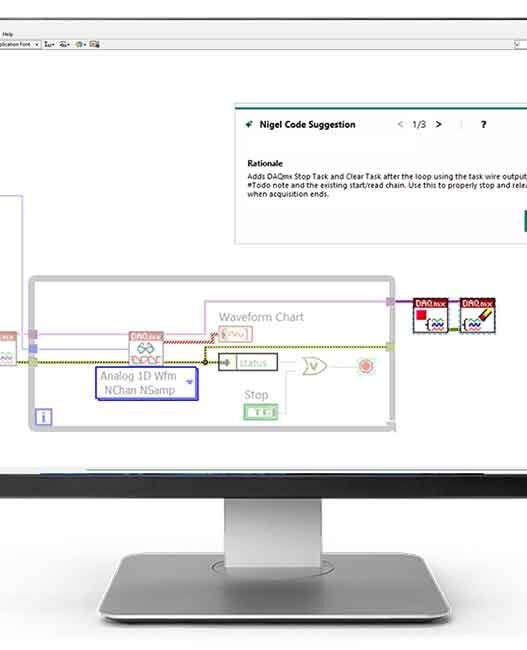

The wide range of PXI-compatible instruments provides additional flexibility. Even if a required instrument is not already available, the extensive ecosystem makes it likely that a suitable alternative can be found. NI’s LabVIEW software suite is a natural companion to PXI systems. Validation engineers value Instrument Studio for its ease of use when quickly observing signals and understanding device behaviour.

LabVIEW also supports rapid prototyping and scales efficiently for production environments, thanks to its ability to compile and execute tests quickly. The entire system is supported by TestStand, which acts as the glue that holds the test infrastructure together. With built-in multi-parallel processing, TestStand makes it easy to scale to higher test volumes. Its powerful debugging tools further support fast test development and ongoing maintenance.

“Together, these tools and methodologies allow Pragmatic to overcome the challenges of fast-paced, scalable production while maintaining high-quality validation and test processes,” notes Dennett.