Melexis has introduced a new inductive position-sensing chip aimed at robotics, industrial automation, and emerging mobility systems, as demand grows for compact, high-precision alternatives to optical and magnetic encoders.

The Belgian semiconductor group said that the latest model in its MLX90514 line provides absolute position measurements via an SSI digital output, offering high noise immunity for use in electrically and mechanically demanding environments. The device uses a contactless inductive technique, which Melexis argues delivers more stable and repeatable performance than established encoder technologies.

The chip’s dual-input architecture processes signals from two coil sets, allowing the device to compute vernier angles on-chip. This enables engineers to measure, for example, both input and output shaft positions within a single system, reducing external circuitry and ensuring synchronised readings. Melexis said the approach can support enhanced functional safety in applications such as robotic joints, industrial motors, and e-bikes.

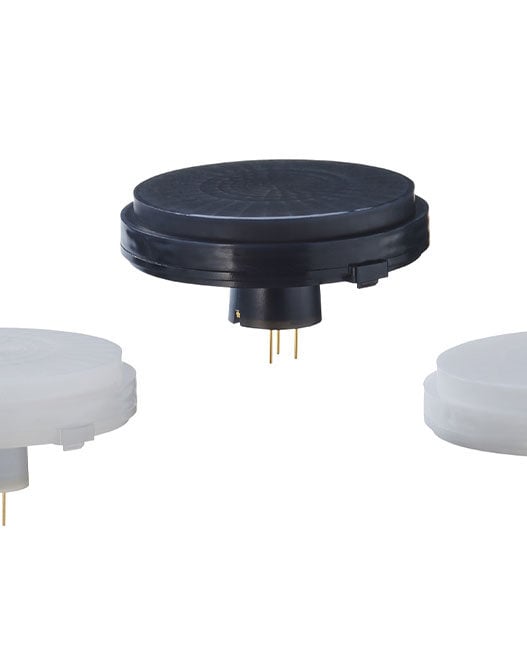

The MLX90514 operates from a 5V supply and supports rotary and linear measurements, with coil diameters from 20mm to 300mm and linear displacements of up to 400mm. The company claims up to 16-bit resolution, zero-latency readings, and accuracy better than 0.1°, allowing for fine control in systems that require rapid and repeatable response. Configuration is limited to a small number of parameters, including offset compensation and linearisation, which Melexis said would simplify deployment.

Because the sensor requires no permanent magnet, the design avoids materials sourcing issues associated with magnetic solutions, while its PCB-based coil structure is intended to reduce assembly time and overall cost. The company said the device is also more resilient than optical encoders to dust, contamination, and mechanical wear. All signal processing is carried out on-chip, helping to reduce board space and the bill of materials.

“The MLX90514 brings a new level of simplicity and precision to position sensing,” said Lorenzo Lugani, Product Line Director at Melexis. “This dual-input IC directly addresses the challenges of robotics, industrial automation, and mobility applications, streamlining integration and reducing system complexity.”