Hall sensors are solid-state devices that convert magnetic fields into electrical signals. They are widely used because they allow contactless sensing, meaning there is no physical wear, high reliability, and consistent performance over long periods.

There are three primary types of Hall sensor used in modern electronic systems: Hall switch sensors, linear Hall sensors, and 3D Hall effect sensors. While all three are based on the same physical principle, their outputs, capabilities, and use cases differ significantly. Choosing the correct type depends on whether an application requires simple on/off detection, continuous measurement, or multi-axis positional awareness.

This article looks at each type in turn, explaining how it works, what it does, and where it is best used.

Hall switches

What is a Hall effect sensor (digital switch)?

A Hall switch is a digital Hall effect sensor that detects the presence or absence of a magnetic field and produces a binary output.

The underlying principle is the Hall effect, which occurs when an electric current flows through a conductor or semiconductor placed in a magnetic field. The magnetic field causes the moving charge carriers to deflect slightly, creating a small voltage at right angles to the current flow. This voltage, known as the Hall voltage, is proportional to the strength of the magnetic field and the amount of current flowing through the material.

The effect was discovered in 1879 by Edwin Hall. Practical Hall sensors became viable much later, once semiconductor manufacturing matured, and saw early adoption in military and aerospace systems during the mid-twentieth century.

In a Hall switch, the sensor circuitry continuously monitors the Hall voltage and compares it to a predefined threshold.

What is its function?

Hall switches provide simple on/off detection. When the magnetic field exceeds a set threshold, the output switches state, for example, from LOW to HIGH. When the field drops below a release threshold, the output switches back.

Most Hall switches include hysteresis, meaning the switch-on and switch-off thresholds are intentionally different. This prevents output chatter or noise when the magnetic field strength is close to the switching point.

Where is it best used?

Hall switches are well-suited to applications where only the presence or absence of a magnetic field needs to be detected. Typical uses include door and lid sensors, end-stop detection, speed sensing by counting gear teeth, and simple position sensing in automotive, industrial, and consumer systems.

Linear Hall sensors

What is a linear Hall sensor?

A linear Hall sensor is a magnetic transducer that produces a continuous, analogue output voltage proportional to the strength of the magnetic field applied along a single axis.

Unlike a Hall switch, which only reports whether a threshold has been crossed, a linear Hall sensor reports how strong the magnetic field is at any given moment.

What is its function?

Linear Hall sensors measure magnetic field intensity along one axis, often referred to as a one-dimensional or 1D measurement. As the magnetic field increases or decreases, the output voltage changes linearly within a specified range.

This makes it possible to infer position, distance, or current by observing how the magnetic field changes relative to the sensor. For example, as a magnet moves closer to or further away from the sensor, the output voltage changes smoothly rather than switching abruptly.

Linear Hall sensors are typically ratiometric, meaning their output voltage scales with the supply voltage, which helps maintain accuracy in electrically noisy environments.

Where is it best used?

These sensors are commonly used in proximity sensing, linear position sensing, current measurement, and motion tracking. Examples include throttle position sensors, pedal position sensing, brushless motor commutation, and non-intrusive current sensing in power electronics.

3D Hall effect sensors

What is a 3D Hall sensor?

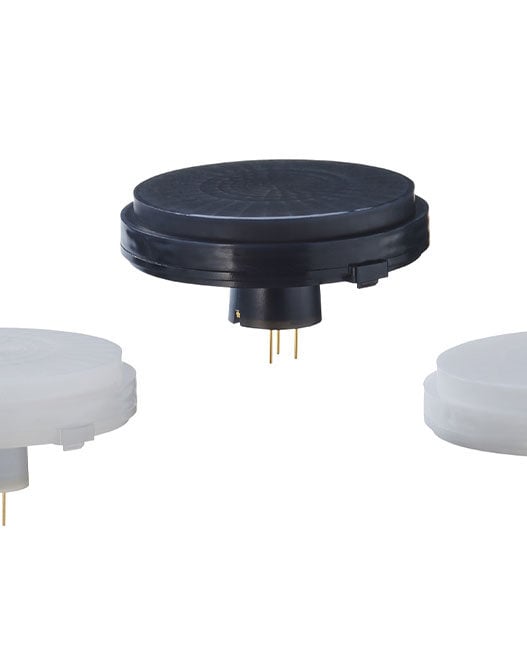

A 3D Hall sensor measures the strength and direction of a magnetic field in all three spatial dimensions.

Instead of using a single Hall element, a 3D Hall sensor integrates multiple Hall plates oriented along different axes on a single chip. This allows the sensor to independently measure the X, Y, and Z components of the magnetic field.

What is its function?

By measuring all three axes simultaneously, 3D Hall sensors can calculate complex spatial information such as angular position, rotational movement, and multi-directional displacement.

On-chip signal processing, often implemented using an application-specific integrated circuit, combines these measurements to determine precise position and orientation. This approach allows accurate angle and position sensing even when the magnet is misaligned or subject to mechanical tolerances.

Another advantage is improved immunity to stray magnetic fields, as unwanted field components can be mathematically filtered out.

Where is it best used?

3D Hall sensors are best suited to applications requiring compact, high-precision, and contactless multi-axis sensing. Typical uses include rotary knobs, joysticks, steering angle sensing, robotic joint feedback, and tamper detection systems.

Choosing the right Hall sensor

All Hall sensors rely on the same physical effect, but their outputs and capabilities differ. Hall switches are ideal for simple digital detection, linear Hall sensors are suited to continuous single-axis measurement, and 3D Hall sensors enable advanced positional awareness in compact designs.

As with any sensing technology, selecting the correct type is essential. Understanding what information an application truly needs to measure helps ensure accuracy, reliability, and long-term performance.