A research team from the University of Binghamton’s Thomas J. Watson College of Engineering and Applied Science have discovered a fast, simple, and affordable way to harvest the thin metallic layer of a gold CD, and then turn that layer into a flexible biosensor.

What is a biosensor?

A biosensor is an analytical device, and it is used to detect the presence of chemical substances using a combination of biological components with a physiochemical detector.

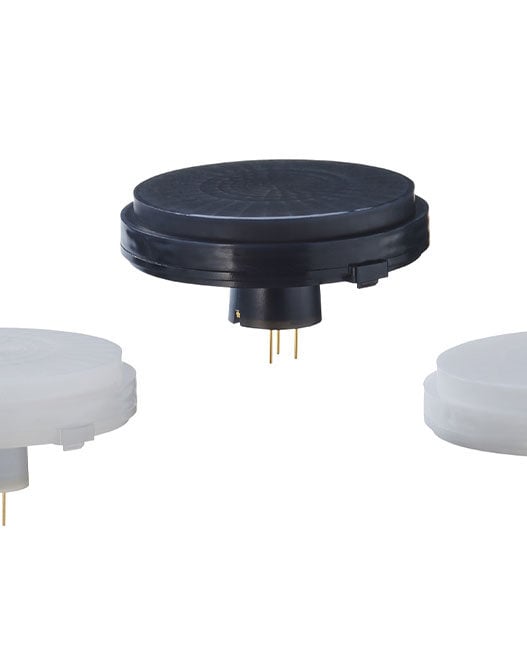

Biosensors are made up of three main elements – a bioreceptor, a transducer and an electronic system, and they are made by having an electrode pattern printed onto a plastic substrate. The substrate is then coated in a conductive polymer casing and a protein (enzyme or antibody) is attached to it.

How does the CD-sensor work?

During his research, Matthew Brown, PHD ’22, found that previous attempts to construct biosensors from CDs meant that the sensors still retained a rigid structure, and that they had a more limited number of applications than he and Assistant Professor Ahyeon Koh, Department of Biomedical Engineering, hoped to achieve.

To combat this, first they devised a plan to remove the metallic layer from the plastic element using a chemical process – and sticky tape.

“When you pick up your hair on your clothes with sticky tape, that is essentially the same mechanism,” Koh said. “We loosen the layer of metals from the CD and then pick up that metal layer with tape, so we just peel it off. That thin layer is then processed and flexible.”

They then purchased a Cricut cutter – an off-the-shelf machine used by crafters to cut designs from numerous types of materials – and used this to score pre-determined patterns on the recycled metal. Once the element is separated, the flexible circuits can then be stuck onto a person.

What does it do?

The sensor can be used to monitor heart and muscle activity in humans as well as their glucose, lactose, PH and oxygen levels. Using Bluetooth, these sensors can be communicated to the end user via a smartphone app.

From gold to silver

At present the team use gold CDs, which are harder to come-by. However, Brown said: “We used gold CDs, and we want to explore silver-based CDs, which I believe are more common. How can we upcycle those types of CDs with the same kind of process? We also want to look at if we can utilise laser engraving rather than using the fabric-based cutter to improve the upcycling speed even further.”

Cheap, fast, sustainable – and readily accessible

The sensors take up to 30 minutes to create, the process doesn’t release any toxic chemicals, and they cost around $1.50 per device to make.

Koh plans to leave a box on campus where people can donate their old CDs. The team also hope to instruct people on how they could make these sensors themselves without having an engineering background.

“Maybe we can create a box on campus where we could collect CDs,” Koh said. “We also could have more generalised step-by-step instructions on how to make them in a day, without any engineering skills. Everybody can create those kinds of sensors for their users. We want these to become more accessible and affordable, and more easily distributed to the public.”

Electronic waste was a big driving force behind this concept, due to the short lifespan of ever-evolving electronic devices as consumers upgrade to the latest devices. And Koh, who came up with the CD-sensor concept almost a decade ago, is pleased to see it now taking shape.

Biosensors are fascinating devices and can be used for numerous applications, and as the world is driving innovation towards a more green and sustainable economy, sometimes the simple solutions are the kindest.