Size and efficiency matter in high end applications

To meet demands of miniaturisation in electronic systems, power supplies will increasingly become more compact over time with the high end industrial and medical device markets in particular set for sustained growth over the next decade

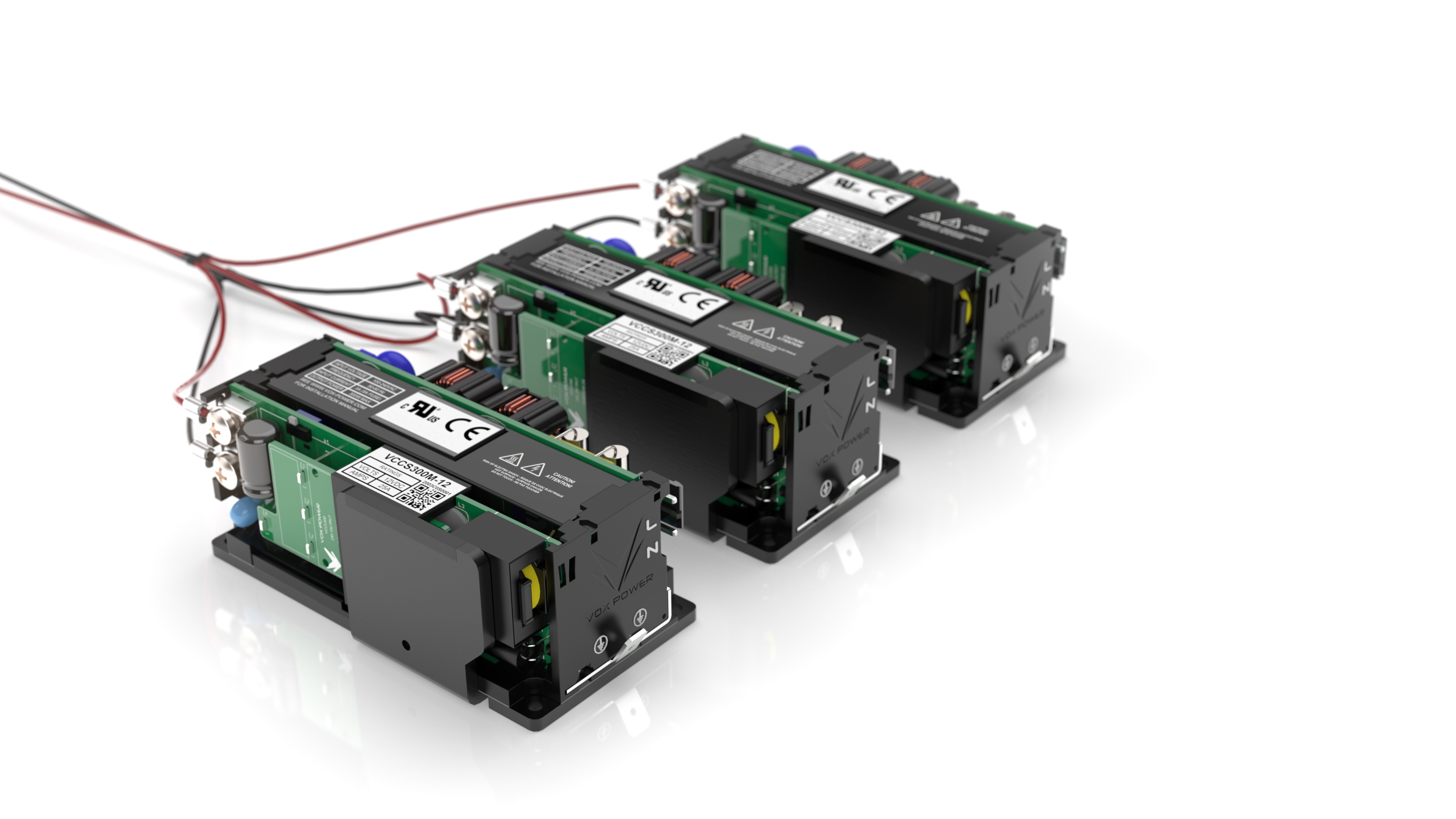

A fanless power supply, the VCCS300, from Vox Power is approved to the latest medical (IEC/UL 60601) and ITE (IEC/UL 62368) safety standards. The fanless design focuses on high efficiency and reliability to offer design engineers a high degree of flexibility during system integration, especially home healthcare and laboratory applications, robotics and automation.

The true conduction-cooled power supply delivers best in class performance when used in a conduction, convection or forced air-cooled arrangement. Weighing only 310g, it is capable of delivering 300W of output power from a tiny 2.0 x 4.0 inch (50.8 x 106.6mm) package achieving power densities in excess of 23W/in3 and, depending on the chosen cooling technique, can deliver up to 80% more power than competitor products in the same package, says the company.

The increased output power allows system designers to achieve three results. The first is to increase system functionality without increasing the size of a product to accommodate larger power supplies. This saves on redesign costs and time to market.

Secondly, it reduces the size of products by eliminating larger power supplies enabling slimline aesthetics whilst also saving on freight costs and carbon emissions. It is also claimed to increase system reliability by reducing internal system temperatures.

Figure 1: The VCCS300 series delivers 300W in a compact form factor

In-depth understanding

Designing high density power supplies requires an in-depth understanding of the interaction and trade-offs between the electrical design, mechanical design, thermal management, electrical safety and EMI performance. Critical elements to reducing the size of a power supply are high efficiency and how design engineers deal with the challenge of internal heat dissipation. Inefficiencies generate heat which, if not removed effectively, can cause excessive product temperatures leading to early failures or reduced long term reliability. When a 300W power supply is only 90% efficient it produces 33W of wasted energy in the form of heat which must be removed. However, when the same 300W power supply is 95% efficient it produces only 16.5W of waste heat.

Excessive heat can be removed through any combination of natural convection, conduction or forced air cooling techniques. Conduction cooled products give the customer the flexibility to choose the best cooling system for an application. When mounted correctly, the right cooling techniques allow for very effective heat dissipation enabling full power operation of the VCCS300, for example, is up to 40°C ambient. By bringing units together, either in parallel or in series, output power can be scaled to 600W, 900W and beyond making the product suitable as a power platform serving multiple products with varied power output requirements. The output of the power supply is body floating (BF) -rated for medical applications and complies with various MIL-STD standards making it suitable for ruggedised environments.

.jpg)

Figure 2: Advanced topologies and materials contribute to the conduction-cooled, high density design

Design topologies

The VCCS300 series combines design topologies and select components with a holistic system design methodology to achieve efficiencies of up to 95%. The high efficiency is complemented by attention to circuit board layout and mechanical construction to ensure that heat generating components, such as power switches and magnetics, are assembled in way which optimally balances heat distribution throughout the product. The use of advanced circuit board materials increases thermal diffusivity providing for better and faster heat transfer into the integrated baseplate. The baseplate provides a simple interface which the end user can then connect to a metal chassis or a system heatsink to facilitate conduction cooling which allows delivery of up to 300W of output power at 40°C without any system fans.

The high efficiency levels and good thermal management eliminate the requirement for a dedicated cooling fan which is very useful in compact higher power applications that have virtually no airflow. For larger systems which have a built-in system fan, the VCCS300 can deliver full power at 50°C with as little as 1m/s of system airflow.

During product design, engineers simplified complex circuits, reduce component count and eliminate design challenges at source. Meeting stringent medical EMC standards in a power supply is always a significant challenge and many manufacturers tend to design a bigger filter to overcome this problem. Vox Power has spent many hours of research, circuit simulations, testing and optimisation to eliminate the sources of EMI noise to result in a small EMI filter to reduce size without compromising performance. The product meets class B limitations for both conducted and radiated emission standards (EN55011) with several dB margin throughout the full frequency range. Committing the time and resources to identifying and eliminating EMI sources throughout the design not only helps to reduce product size but also enhances product reliability.

The increased isolation, creepage and clearance requirements for medical power supplies also inhibit size reduction. In the new unit, we gave careful consideration to the design of mechanical insulators to achieve a BF-rated output without impacting thermal performance or product size.

Vox Power says the VCCS300 converges two power market segments. The first is miniaturised applications which may have limited space for a power supply but have increased power requirements to achieve the required application feature set. The power supply addresses this challenge by offering a much higher output power. This enables additional features and gives customers an advantage in their market. Example applications include home healthcare, mobile equipment, ventilators, respirators and dental equipment.

The second segment is higher power applications where customers wish to reduce the size of their applications but are limited because higher power supplies are only available in larger footprints. The VCCS300 delivers up to 300W of output power which has historically only been available from much larger (5.0 x 3.0 inch / 127 x 76mm) power supplies. Examples of these applications include medical and industrial lasers, automation, robotics and 3D printing.

About the author:

Marco Prinsloo is CEO of Vox Power