Navitas Semiconductor has announced a new range of gallium nitride (GaN) and silicon carbide (SiC) power devices designed to support NVIDIA’s next-generation “AI factory” data centre architecture, which operates on an 800V direct current (DC) distribution system.

The US-based semiconductor group said the shift from conventional 54V in-rack power distribution to 800V DC represents a “transformational” step for high-performance computing (HPC) and artificial intelligence (AI) infrastructure, enabling greater efficiency and scalability as data centres move towards megawatt-scale power requirements.

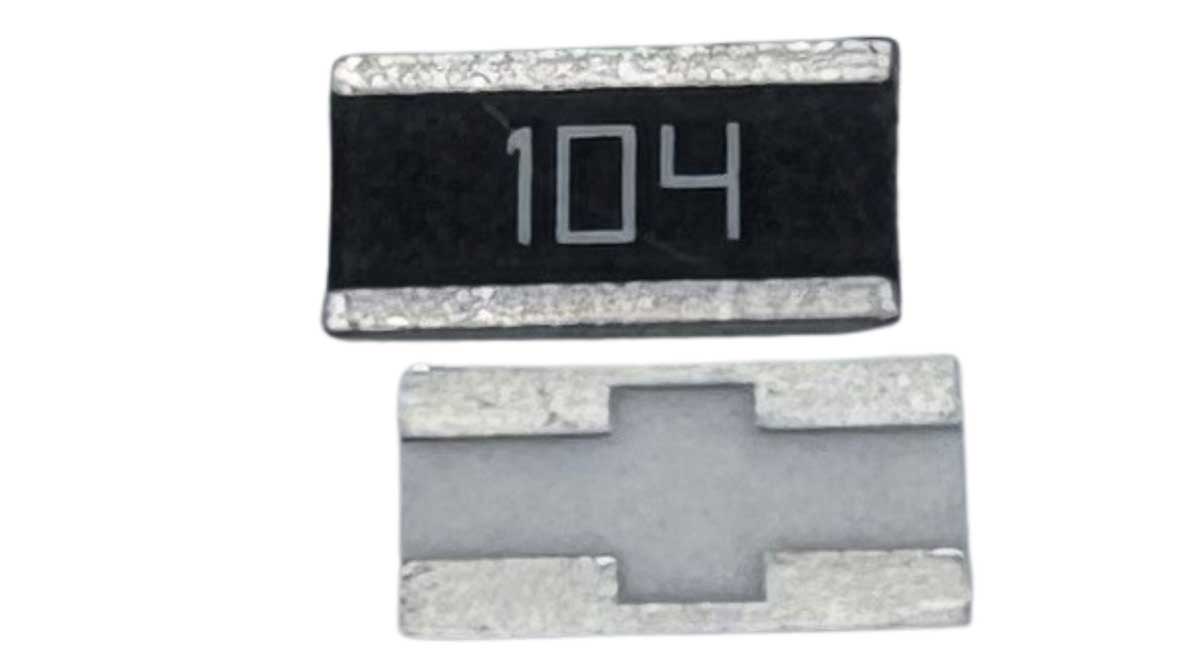

Navitas’ new line-up includes 100V GaN field-effect transistors (FETs) for GPU power boards, 650V GaN devices with integrated safety features, and high-voltage SiC components designed for use across multiple stages of the data centre power chain. The company said these devices are optimised to deliver higher power density, improved thermal management, and reduced conversion losses in large-scale AI deployments.

The 800V DC architecture being promoted by NVIDIA allows power to be converted directly from 13.8kV alternating current to 800V DC within a data centre’s power room. The approach, which uses solid-state transformers and industrial rectifiers, eliminates several traditional conversion stages and reduces resistive losses and copper consumption.

“As NVIDIA drives transformation in AI infrastructure, we’re proud to support this shift with advanced GaN and SiC power solutions that enable the efficiency, scalability, and reliability required by next-generation data centres,” said Chris Allexandre, Navitas’ President and Chief Executive. “The transition from legacy 54V architectures to 800V DC is not just evolutionary — it’s transformational.”

The company’s 100V GaN FETs are produced using a 200mm GaN-on-silicon process through a manufacturing partnership with Taiwan-based Power Chip, allowing for higher-volume output. The 650V GaN portfolio includes the firm’s GaNSafe power integrated circuits, which combine drive, sensing, and protection features with short-circuit response times of 350 nanoseconds and electrostatic discharge protection up to 2kV.

Navitas’ GeneSiC SiC devices, meanwhile, span voltages from 650V to 6,500V, targeting applications in grid infrastructure and energy storage. The technology has been deployed in projects with the US Department of Energy, according to the company.

The development aligns with a wider industry shift toward so-called “AI factories” — large-scale, synchronised data centres purpose-built to handle intensive computing workloads. The move to 800V DC systems is seen as essential to scaling such facilities efficiently while managing the growing thermal and electrical demands of AI processors.