QuickLogic products have long been valued by military and avionics designers for their robust performance in harsh conditions, and with the PolarPro QL1P1000 we have boosted the logic density to match the requirements of today’s more sophisticated systems, said Brian Faith of QuickLogic.

The QL1P1000 platform offers the reliability and capacity needed for the most demanding military applications, supporting the full mil-spec temperature range of -55 to +125 degrees C. The platform also addresses the shock and vibration requirements of military and avionics applications by employing robust packaging to reduce sensitivity to mechanical stress.

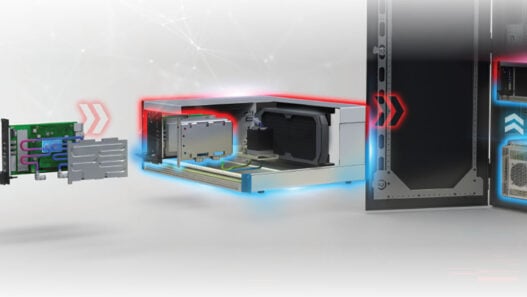

PolarPro’s architecture moves the ultra-low-power consumption FPGA (field programmable gate array) formula to a new level, adding further circuitry to optimize performance and power consumption. The designed-for-purpose architecture means that interfacing functions may now be implemented with a very small bill of materials and in a small space. Notably, the FPGA incorporates an ‘instant’ deep-sleep standby mode that reduces power consumption to less than 10 microamps. This is up to 1,000 or 10,000 times lower than Flash- or SRAM-based FPGAs respectively. Critically, this headline power conservation level is assured in all situations, thanks to circuitry that isolates the I/O pads from the logic core when on standby.

QL1P1000 is non-volatile and does not require an external configuration memory, nor can it be read after programming. Keeping design details and security codes embedded in the platform completely unexposed to the outside world makes the platform virtually impossible to reverse-engineer, clone, or tamper with.

All of the logic is implemented using the company’s unique ViaLink programmable metal-to-metal interconnect. With ViaLink, circuit connections are fabricated vertically, rather than on a planar layer. This means that reverse engineering techniques aimed at understanding a device by ‘unpeeling’ it layer by layer, are ineffective.

An alternative approach to reverse engineering might be to slice vertically through a device and then use a FIB (focused ion beam) tool to view the connectivity. However, a typical QuickLogic device has millions of fuses, each one of which would require multiple cuts and views to see if used and typically less than 2% of the fuses are actually programmed for any specific design. The likelihood of being able to make all these cuts successfully without damage, combined with the enormous amount of time required, renders this method of reverse engineering impractical.

The secure nature of QuickLogic’s fabrication process means that its technology has been used in many sensitive defence related applications, and QuickLogic has a strong security chain in place to protect secret keys during device manufacturing.

The technology’s reliable, non-volatile programming approach enables ‘instant-on’ operation, which is ideal for immediate recovery from brown-out situations. In addition, QL1P1000 has high immunity from Single Event Upsets (SEUs) or ‘soft errors’. PolarPro QL1P1000 is available immediately.