It’s difficult to imagine life without the electric motor. From toothbrushes to lifts, electric vehicles (EVs), and industrial automation systems, the electric motor enables a wide range of processes across diverse fields. But, with billions deployed globally and the numbers set to rise further in the coming decade, the energy consumption of electric motors is attracting regulatory attention.

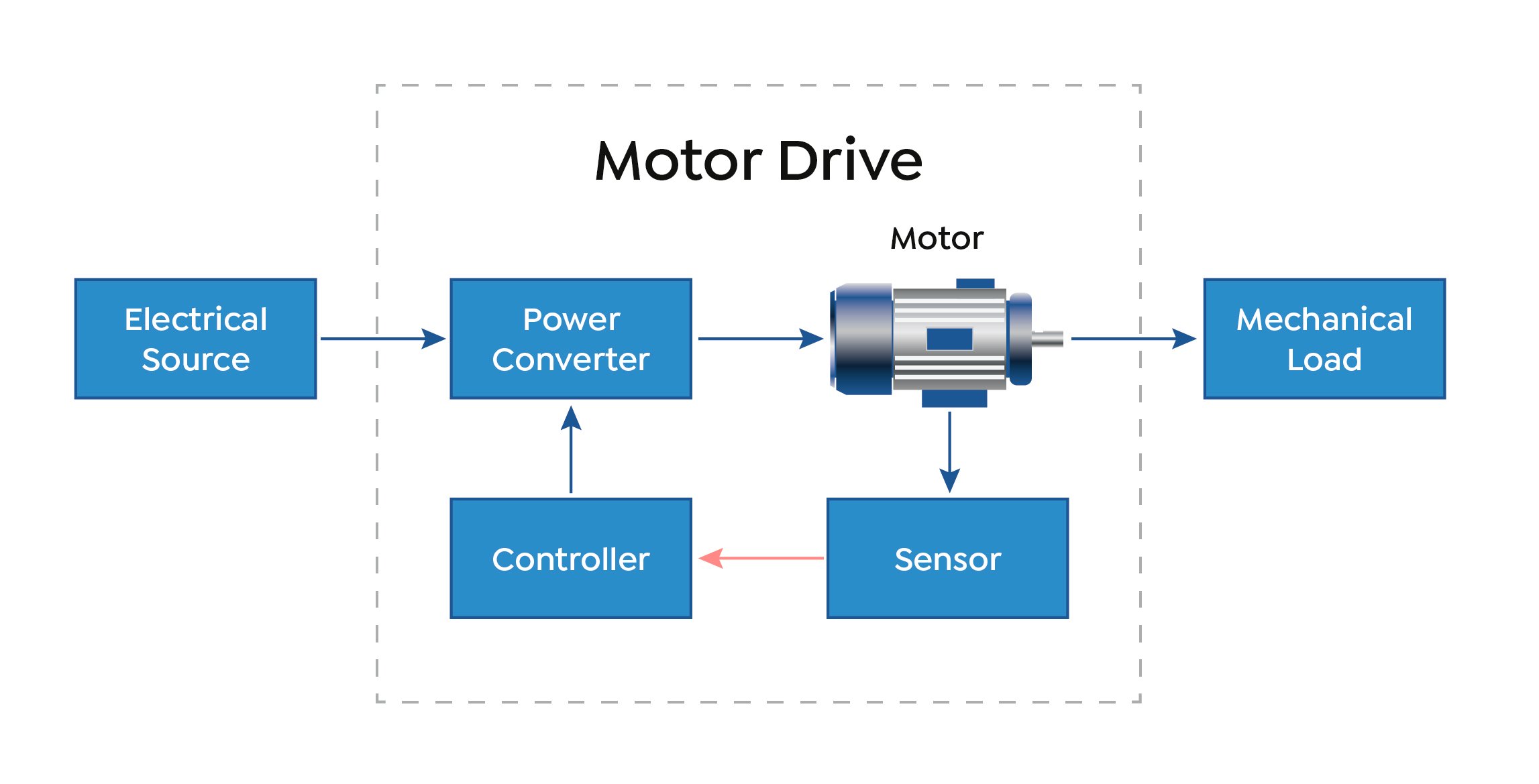

The electric motor is a core component of the Electric Motor Drive System (EMDS), pictured in Figure 1, which converts electrical energy into a desired mechanical output – typically the speed and torque of the motor and the position of its shaft.

In a world increasingly focused on emissions reduction, designers of electric motor drive systems are under pressure to meet increasingly stringent efficiency standards.

Silicon MOSFETs and IGBTs have long been the devices of choice for power conversion in motor drives, but the newer, wide bandgap materials (SiC and GaN) offer significant improvements in efficiency and power density.

This article examines the context behind the increased demands for efficient electric motor drives before describing the advantages to be gained from designing with SiC and Gan devices.

EBV Elektronik is ideally placed to support the EMDS development cycle, from component selection to advanced technical support and training services.

The ubiquitous electric motor

In a recent report, the European Commission (EC) estimated that circa eight billion electric motors are in use in Europe alone – and this number is set to grow. Key drivers of this buoyant market include the growing numbers of EVs on our roads, rising levels of industrial automation, increasing integration of renewable energy systems, growing demand for home appliances, and rapid industrialisation in developing countries.

Unsurprisingly, given such large numbers, electric motors are responsible for a significant amount of global CO2 emissions. Consuming 43 to 46% of all electrical energy generated globally – and almost half of that generated in Europe – the efficiencies of EMDS are coming under increased scrutiny by regulators. Over 50 countries around the world, including the EU nations, China, and the USA, have implemented regulations governing the efficiency of electric motors, such as the IEC 60034 and IEC 61800 series of standards, which provide guidelines for the design, application, and testing of EMDS. The EU estimates that compliance with these standards will save 110TWh of energy – roughly equivalent to the electrical energy consumption of the Netherlands – by 2030. These savings require all new EMDS to meet higher efficiency classes by 2030. However, most installed motors are not at these levels. Further innovation is therefore required to achieve these greater efficiencies and, as improvements in motor technology become more costly, developers are turning their attention to the power conversion electronics within the drive system.

Semiconductor technologies in motor control

The power conversion electronics within the EMDS transform the electrical power input – usually AC mains – into a voltage and current waveform that can be directly applied to the motor. By precisely controlling the power and frequency of the output delivered to the motor, energy consumption is optimised, smooth motor acceleration and deceleration is achieved, and torque can be precisely controlled across a wide speed range.

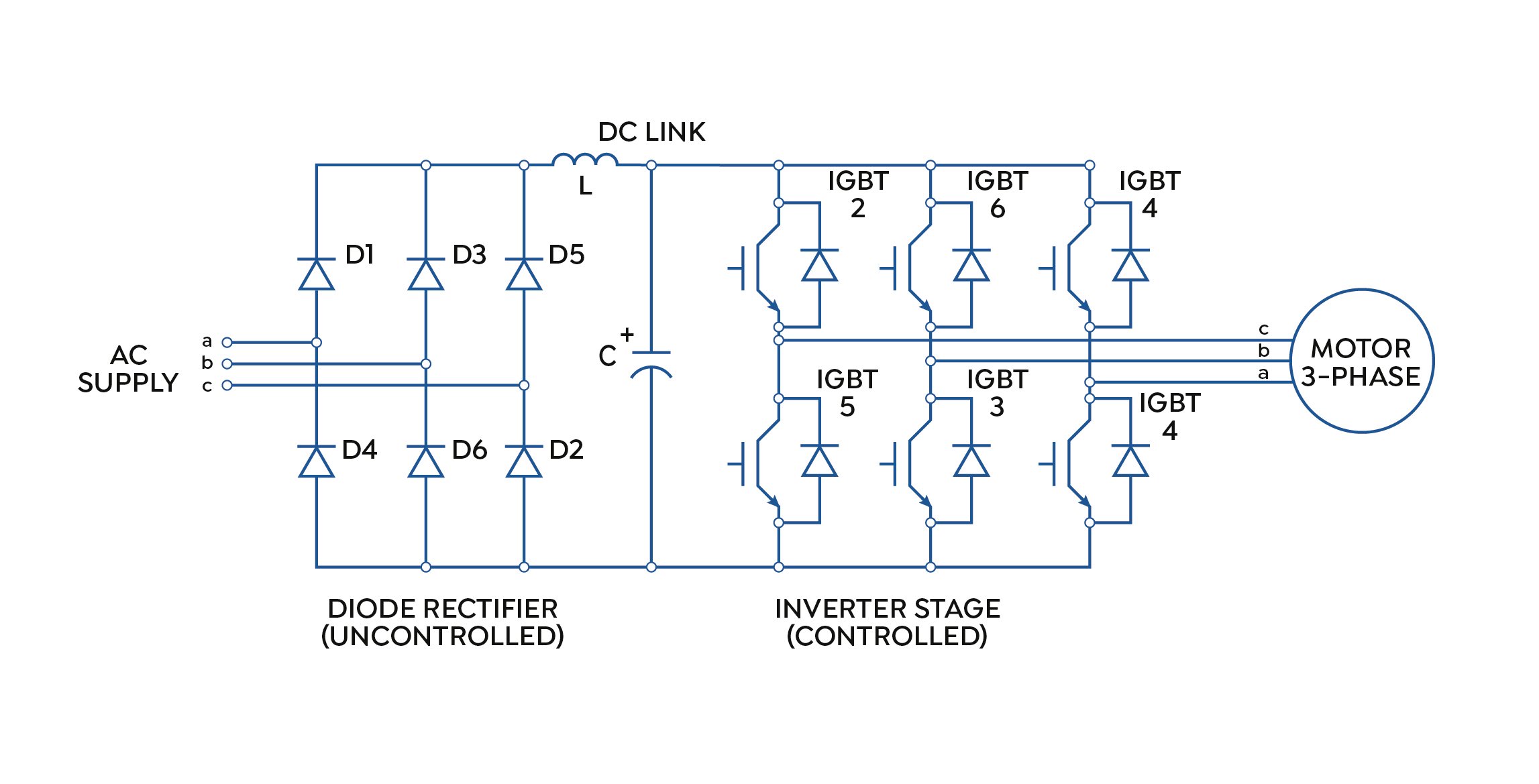

Key power conversion stages for an inverter-controlled motor include:

AC to DC (Rectification): the AC mains power is first converted to DC bus voltage

DC to AC (Inversion): the DC power is then converted to AC voltage or current

Power conversion solutions are based on several well-used topologies, depicted in Figure 2, with switching techniques used to improve efficiency and reduce the size of passive components. Silicon MOSFETs and IGBTs, with their low conduction and switching losses, have traditionally been used in these switching stages. But while these devices’ performance has improved considerably over the years, the relentless drive for improved efficiencies and power densities is increasing the attractiveness of SiC and GaN technologies.

The wide bandgap technologies: SiC and GaN

In comparison with silicon, a single chemical substance, SiC and GaN are both compound semiconductors – SiC a compound of silicon and carbon, and GaN a compound of gallium and nitrogen. SiC and Gan both have wider bandgaps than silicon – 3.3 and 3.4eV versus 1.1eV – giving them higher dielectric breakdown strength and higher withstand voltages.

Although both materials are highly efficient with lower switching losses than silicon, each has distinct characteristics suited to different applications. SiC can handle higher voltages – commercially up to 3.3kV, has higher current carrying capability and better thermal conductivity, making it a good fit for applications such as automotive and locomotive traction inverters, high-power solar farms, and large three-phase grid converters. GaN devices, on the other hand, are typically lower voltage (up to 750V) but can operate at higher switching frequencies due to GaN’s higher electron mobility. GaN therefore supports high power density applications, including DC/DC converters and inverters.

Furthermore, GaN is also cheaper to produce than SiC and is beginning to make inroads into the EMDS market, replacing silicon MOSFETs. Its lower conduction and switching losses significantly improve efficiencies, reducing heat loss – and hence the need for, and cost of, cooling systems. GaN’s high carrier mobility, low on-resistance, and low parasitic capacitance enable GaN transistors to operate at frequencies of several or even tens of megahertz, up to 100 times faster than silicon devices. These capabilities reduce the size and weight of the components used in EMDS, while also improving efficiency.

As regulations demand ever higher efficiencies, developers can leverage GaN’s capabilities to design highly efficient and compact EMDS, suitable for high speed and precision control applications, including robotics and industrial automation.

The dynamic EMDS market

The global market for electric motors was valued at $145.15 billion in 2024 and is projected to reach $258.17 billion by 2032, a CAGR of 7.52% over the forecast period. Driven by trends such as the growth in EV numbers, increased industrial automation, and rising demand for household appliances, this dynamic market will create lucrative opportunities for developers who can get to market quickly and with innovative solutions.

While IGBTs and MOSFETs continue to evolve, an increasing choice and variety of SiC and GaN devices are appearing on the market in new and more performant packaging types. These devices are enabling a multitude of new EMDS solutions, creating innovative applications for the electric motor.

Developers must move quickly to grasp these market opportunities, absorbing knowledge on regulations and technologies, while understanding which devices to use to optimise price and performance. With the pressure on to accelerate time to market and reduce development costs, developers are increasingly relying on strong ecosystem partners such as EBV Elektronik to support them throughout the development cycle.

Easing your path to market

As an EMEA semiconductor distributor, EBV Elektronik has a broad portfolio of devices and components, backed by the resources of our supplier network. Our team is available to support you at any stage, from component selection and multi-sourcing options to technical design support services throughout the development cycle. Additionally, our partners have access to an industry-leading knowledge resource, including workshops, webinars, and training sessions on motor drive technology.