Most people use touch-screens daily, but few stop to wonder about the electronics that makes them possible. Here, Dr Mike Coulson, Analogue Design Manager at ASIC design and supply company Swindon Silicon Systems, discusses how application specific integrated circuits (ASICs) play an integral role in uniting man and machine.

In the last 15 years, the world has witnessed a touchscreen revolution. Touchscreens now feature extensively in our daily lives, not least within our mobile devices, but also in retail, healthcare and industrial settings. More niche applications call for specialised touchscreens that are sufficiently sensitive to detect a human finger through thick glass, through gloves, or even at a distance above the screen’s surface. This human-machine interface (HMI) technology is still evolving, driven largely by advances in the supporting electronics and signal processing.

Electronic challenges

Almost all modern touchscreens use the ‘projected capacitance’ technique, where a matrix of invisible conductors is embedded within the display. At each crossing point, the conductors form coupling capacitances between one another, at least partially through the air above the display.

A finger in close proximity reduces this coupling, albeit by a tiny fraction. The job of the touchscreen controller is to measure the numerous capacitances, usually by driving each wire in turn with a voltage stimulus and thus pushing vanishingly small currents through them. By measuring the many tiny currents simultaneously, and at fantastic resolution, it is possible to perceive the effect of any touches and calculate where they occur.

Upon entering the controller, each wire’s signal is first passed through filtering components to reject interference — perhaps unsurprisingly, given that each wire resembles a long antenna. The signal is then amplified and sampled before being digitised by an analogue-to-digital converter (ADC). The replication of all this componentry, to serve the numerous wires in the panel, represents a significant challenge to the cost and form factor of the electronics.

Because the changes in capacitance are so subtle, great attention must be paid to noise when designing the controller. Furthermore, the many channels must operate at high frequency in order to win an acceptable ‘frame rate’ from the touch panel. Matching between the channels must be good in order to simplify subsequent processing, calling for tight control over circuit properties and stray capacitances. One popular way of improving the signal-to-noise ratio is to drive the wires at moderately high voltage, maximising the currents being measured. However, this requires specialised components to switch and distribute the excitation, and a dedicated circuit to generate it from whatever low-voltage source is available.

The application of ASICs to these challenges

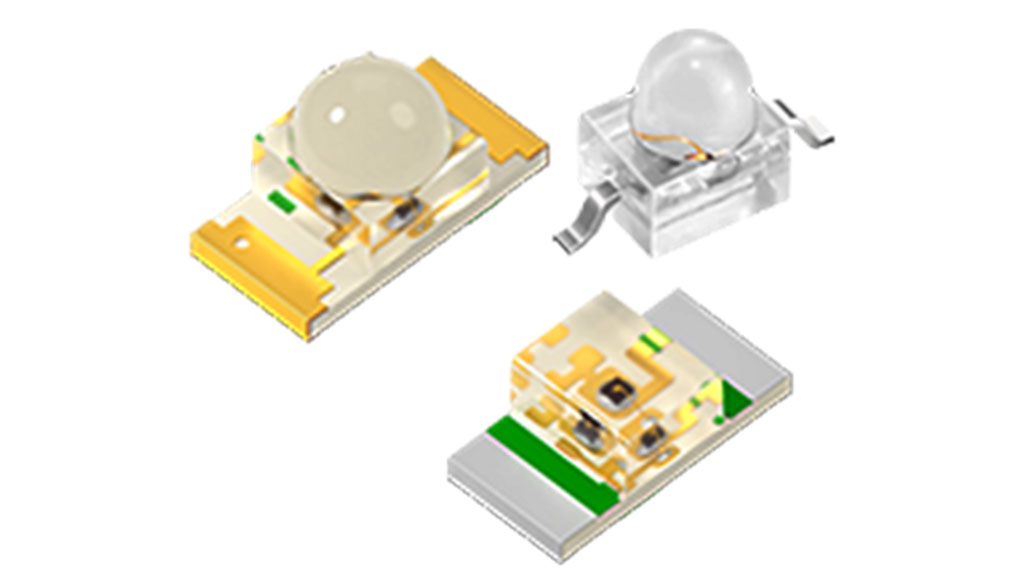

When such systems are initially prototyped, these electronic functions are provided by a multitude of off-the-shelf integrated circuits (ICs) supported by an array of capacitors and resistors. This is the optimal approach when prototyping, as it provides the opportunity to understand what specifications are important to the solution. It also gives the developer freedom to experiment with novel hardware approaches to the problem in hand. But to translate a prototype into a cost and performance optimised high volume product, developers will integrate as much of the circuitry as possible into an ASIC.

Swindon frequently designs and supplies custom, high-throughput, multi-channel solutions into human-computer interface applications, optimising the overall bill of materials and achieving form factors that are otherwise impossible. Modern high pin-count packages accommodate many channels in a single part, with excellent matching in properties. Because the cost of replicating identical channels is relatively low, the ASIC approach can be extremely effective in these applications. Furthermore, novel circuits are protected from prying eyes — an ASIC is far more difficult to reverse engineer than discrete parts wired together in plain sight. As Swindon does not develop or sell standard parts on the open market, customers can be confident that their solution and IP benefits them, and them alone.

The ASIC design process itself is heavily based on simulation, incorporating all relevant parasitic capacitance, resistance and inductance so that performance is assured. Noise, being so critical to touch-screen applications, can be accurately predicted and mitigated. The digital processing can also be integrated, either by deployment of processor IP or of custom synthesised logic, and the entire signal path can be optimised as one.

By honing the specifications of each element, silicon area and design effort is expended only where absolutely necessary. In contrast, when designing with off-the-shelf ICs, it is inevitable that some aspects will be over-engineered because these components are sold with versatility in mind.

Designing an ASIC

Whilst not always necessary, a working prototype system provides a superb basis for an initial discussion with an ASIC supplier. When customers first engage with Swindon, its priority is to fully understand their concept, allowing it to quickly assess whether a custom solution might benefit them and if so, to identify the optimum system partitioning.

Having established and captured the customer requirements, the chip is then broken down into analogue and digital blocks, each with its own specification. The design of these blocks is distributed across a team of engineers who are accustomed to relying on sophisticated simulation to guide their work. Unlike many other fields of engineering, there are no prototypes when designing integrated circuits: nothing is manufactured or measured until the entire design is finished.

Touch-panels are just one application of ASICs, but they serve to demonstrate the value that integration can bring. The benefits are such that an ASIC sits behind every touch-panel we encounter in our daily lives, although we may not realise it. It is impossible to imagine what technology will eventually displace touch: perhaps mid-air gesture control, or brain-computer interfaces? But no matter what triumphs, it is safe to assume that it too will rely on a custom IC.