JEP has the advantages of conventional solder paste and anisotropic conductive paste, i.e., self-alignment and planar insulation, respectively. The epoxy is cured after reflow and provides excellent bonding strength and joint protection. Reliability performance is enhanced as well. PF735-EP307 solder paste adopts the newly designed epoxy-based flux that performs better in regards to printability, longer printing lifetime and better reliability than typical epoxy-based solder pastes.

With the low melting point alloy PF735, the new solder paste can reduce the reflow temperature to below 190°C compared to lead-free soldering, typically 240°C to 250°C, and hence decrease PCB and substrate deformation while saving energy, reducing the thermal stability requirement of PCBs and components, and raising yield rates.

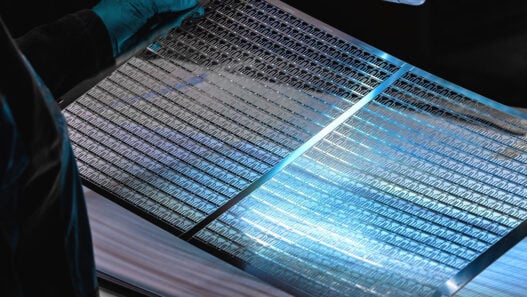

PF735-EP307 is halogen-free (REL0) and complies with RoHS. RoHS 2.0 and REACH. The no-clean paste is applicable to various surface finishes and has a clear flux residue. It is suitable for fine-pitch applications and various IC packages, such as system-in-package (SIP), wafer-level-package (WLP), and flip chip.