A new analysis from Frost & Sullivan, Impact Assessment of Graphene in Key Sectors, expects market revenues to reach $149.1m by 2020.

Sanchari Chatterjee, Research Analyst, Technical Insights, Frost & Sullivan, comments: “The energy sector is one of the prime markets for graphene and will remain so for the next three years. Lithium storage and catalytic system substrates are some of the most demanding application areas of graphene. However, other applications such as energy storage for batteries and capacitors have also been identified.”

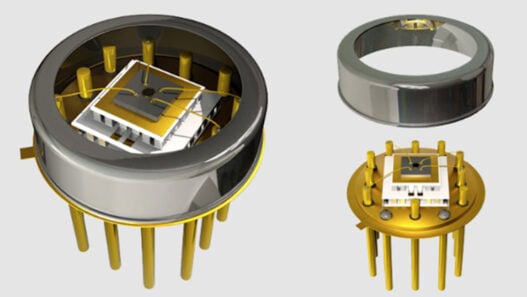

In the electronics sector, graphene is replacing materials like indium tin oxide. While graphene is widely used in flexible electronics, it can further penetrate this sector for the production of minute electronic components and optoelectronics.

In the next three to five years, the adoption of graphene in the electronics and composites sector will increase. Within this time, a number of new markets such as healthcare and personal care are expected to open up for graphene.

However, the absence of large-scale graphene production in a cost-effective and reproducible manner makes commercialisation a major challenge. To date, graphene has been developed mostly at the laboratory level as processes like nano-slicing used during industrial-scale production increase costs and hamper the quality of end products. Exfoliation processes, however, have been commonly used.

“Manufacturers are designing several economical and large-scale production processes to ensure that high-quality graphene can be produced within a short time,” added Chatterjee. “This can significantly reduce commercialisation challenges.”

For instance, although graphene is among the thinnest yet strongest materials in the world, its structural design creates flaws when made into sheets for use in energy applications, compromising performance. Furthermore, the zero band gap of graphene is a major technical drawback as it limits the achievable on-off current ratios.

With the reliability of standalone graphene in doubt, research is on to customise graphene to enable manufacturers to use it in its reinforced and hybrid forms. Overall, corrective R&D and innovative commercialisation techniques can help realise the tremendous potential of graphene that ranges from applications in biomedical to anti-corrosion coatings.