Automated solution to apply traditionally difficult materials

TIM Print is a novel method to apply Laird Performance Materials’ thermal management die cut pads while reducing total cost of ownership. It offers a more robust, reproducible and reliable application process as compared to traditional ‘peel and stick’ and dispensing methods.

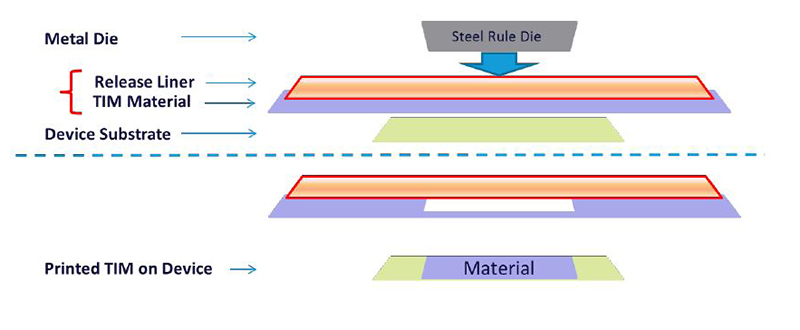

TIM Print uses an automated (or semi-automated) press and die to transfer thermal pad materials from a carrier liner to a substrate (e.g., heat sink, lid, BLS) This method scales well from individual parts to fully automated, roll to roll processing with integrated substrate feed and in-line inspection.

In addition to reducing costs and improving speeds, TIM Print can be used to apply materials that are traditionally difficult to hand apply, thereby reducing scrap and enabling the use of materials with improved properties.

TIM Print reduces Total Cost of Ownership (TCO) by:

- Reducing material cost per assembly

- Increasing customer throughput

- Improving customer yields

- Reducing customer scrap

- Reducing customer rework

- Reducing release liner and tab disposal costs

- Reducing customer supply chain and logistics costs (reduction of part SKUs and inventory)

TIM Print also enables the supply and application of ultra-thin, free standing pads (as thin as 75 microns).

TIM Print features enable:

- Lower Total Cost of Ownership

- Lower TIM pad costs

- Improved customer throughput

- Improved customer yields

- Reduced customer scrap

- Reduced customer rework

- Simplified customer supply chain and logistics

- Enables ultra-thin, free standing TIM pad parts

- Enables easier application of traditionally difficult to hand-apply material

Markets and applications

- Applications that use thin pad Tpcm and Tflex TIMs (less than one millimetre)

- Proven for IceKap

- Proven for Tpcm 580, 780

- Proven for Slim TIM

- Demonstrated for Tpcm 750