Visco is set to spotlight its latest advancements in AI at productronica India 2025. From September 17–19 at the Bangalore International Exhibition Centre (BIEC) attendees can meet Viscom’s experts, at Hall 4, Booth No: H11 to explore the future of electronics manufacturing inspection.

Viscom’s AI-driven solutions are designed to be strategic enablers for electronics manufacturers aiming for 100% defect-free products. Effective inspection relies on proven concepts and methods, such as robust algorithms, precise 3D measurement techniques, and high-resolution image processing.

Building on these foundations, Viscom offers additional AI-powered tools for its inspection systems. Explore Viscom’s smart AI solutions vAI, including AI-based verification, AI-supported image processing and inspection programme generation at the productronica India.

Guido Bornemann, Head of Sales Asia, states: “Viscom’s vAI products are designed to advance the automation of machine processes, tackle complex inspection tasks, and deliver faster results. Developed in-house by our team of AI experts and tested in the field with selected customers, these applications can be integrated into real production environments step-by-step and tailored to individual needs. Viscom emphasises transparency in AI quality, ensuring complete process control for our customers.”

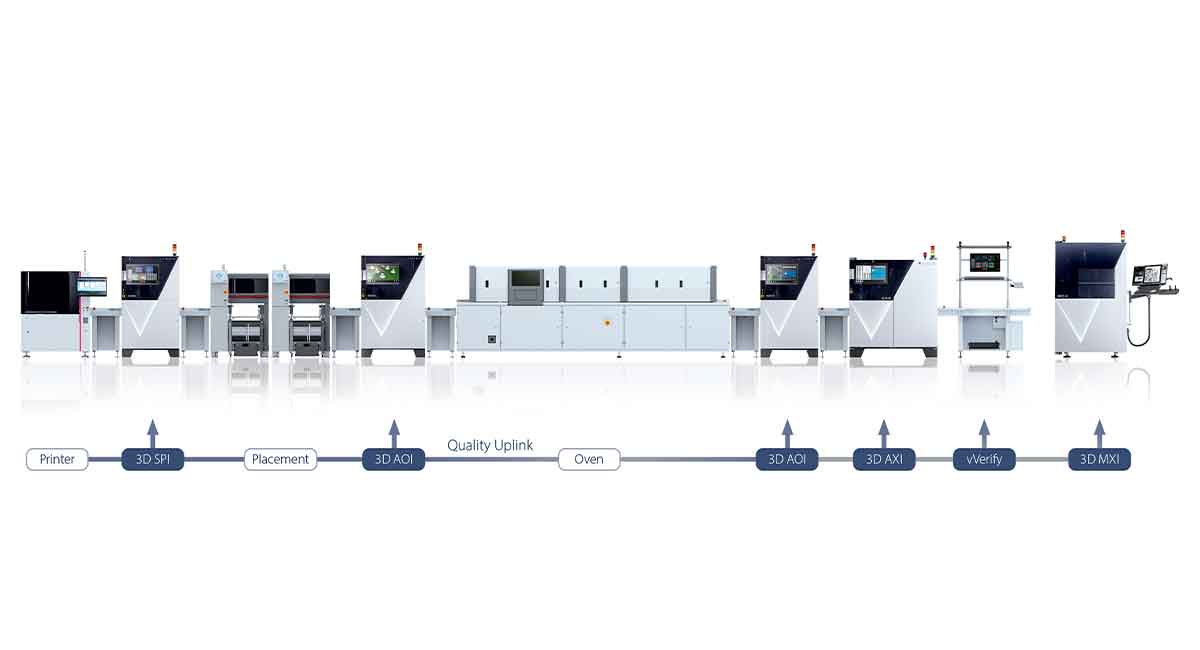

In addition, learn more about the advantages of Viscom’s fully integrated 3D AXI, MXI, AOI, and SPI inspection bundles, which offer significant benefits when sourced from one supplier. Customers benefit from streamlined operations with one set of spare parts, unified software, and seamless communication across the inspection line.

Central to this integration is Viscom’s Quality Uplink software, which intelligently connects inspection images and results from SPI, AOI, AXI and MXI systems. This ensures more efficient process control, support operators at the verification station, reduce human error, and enables the development of improved inspection strategies.

By storing inspection data across all systems, manufacturers gain full traceability and can perform downstream process analyses to enhance productivity, increase first-pass yield, reduce costs, and ultimately improve product quality.

Visitors will also get hands-on experience with Viscom’s software platform, vConnect, which sets a new standard in digital connectivity and process integration across production lines. Via the multipurpose-platform customers can also access Viscom’s vAI Hub: it brings all AI-related processes into one environment. This centralised approach ensures fast adaptation and seamless integration into existing production processes. From void detection in X-ray images to verification of potential defects, the vAl Hub keeps AI implementation efficient and user-friendly.