A California company with a presence across the UK, Europe, and Asia has a compelling solution to legacy switch bottlenecks that are currently hampering the take up of beneficial AI applications.

The global explosion in the implementation of devices that use AI-driven applications is putting pressure on Micro Electromechanical Systems (MEMS) manufacturers to deliver quantum advances in performance to keep up with demand.

With models getting larger and GPUs getting faster, removing bottlenecks becomes critical, meaning chip designers have to turn to faster and faster interconnects. Standards such as PCIe 6 are challenging to implement and even harder to test to ensure their performance is, literally, up to speed.

One of the reasons testing is so difficult is that while AI technology is unbelievably complex, automatic test equipment (ATE) systems are reliant on one of the oldest and most basic components in electronics: the electromechanical relay (EMR).

Electromechanical relays have been in use for over 150 years and are still in operation worldwide as they are crucial components of, for example, industrial controls, automotive systems, and almost every type of consumer electronics. They became ubiquitous because they simply worked. However, in today’s modern world, they do not meet system performance demands and create bottlenecks.

Although the RF relays used in ATE by GPU manufacturers are highly developed, when AI turned to faster buses, these legacy relay solutions soon began to place limits on AI chip production. PCIe 6 transmits at 64Gb/s using 4-level pulse-amplitude modulation (PAM-4). At these speeds, and with the extra challenge of four voltage levels, adding the switches that are needed to automatically test devices is very challenging.

No switch is perfect. Solid-state (SS) switches, which are semiconductor-based, emerged about 30 years ago to fill some void left by EMRs but limited to niche applications and came with significant trade-offs. Using SS switching introduces distortion to the signals on the bus, resulting in loss of signal integrity and potentially making loopback tests – a key element of testing the PCIe 6 bus – impossible. EMRs offer a linear metal-to-metal contact but are physically large. Their size, and insertion loss, degrade the transmission line characteristics resulting in errors and failure.

However, there is now a compelling alternative to EMRs and SS switches that solves the testing challenge in the form of MEMS. This technology enables tiny switches to be created that are many thousands of times smaller than the traditional ones.

MEMS are typically made using silicon-based materials that incorporate microscopic mechanical components such as sensors, actuators, and switches. These components are made using standard semiconductor manufacturing processes, which often involve photolithography, etching, and doping techniques.

That’s not to say that MEMS is a new technology: your smartphone gyroscope probably uses MEMS technology for the sensors for the microphone or to determine which way up your smartphone is being held. But until very recently, their use for switching was limited.

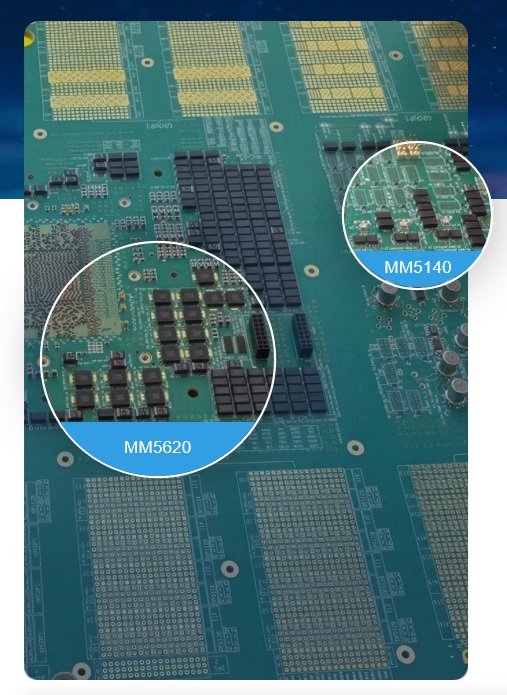

The turning point was a major development by metallurgists at General Electric, who developed a breed of MEMS switch out of new materials that could turn on and off in under 10 microseconds and last over three billion cycles. This breakthrough technology gave birth to Menlo Microsystems (Menlo Micro), a company’s whose driving goal was to reinvent the switch for a modern age.

It was already apparent throughout industry that physically large, relatively slow and electrically imperfect EMRs were struggling to enable the testing of AI devices. Given the emergence of AI, Menlo’s establishment and rapid growth could hardly have been more timely.

Menlo’s technology disruption is an alloy that is used in a semiconductor-like manufacturing process and flex billions of times without failure. This enabled the creation of a switch that provides all the benefits of metal-to-metal contact – but without the drawbacks of the conventional relay. A solution that eliminates the losses and distortion associated with solid state switches; as well as the size and unreliability of EMRs.

These devices offered small size, extremely low on-resistance, high speed, elimination of distortion, and outstanding reliability and ruggedness: features that make the technology ideal for applications from RF beamforming to control of megawatts of power. Not surprisingly, Menlo Micro named its solution the ‘Ideal Switch’.

With PCIe 6 now adopted by the top high-performance AI chip manufacturers, Menlo Micro’s products are widely used in the semiconductor industry to test these vital devices. Recently, the company presented results at a test conference that not only showed that the Ideal Switch was able to support switching of PCIe 6 lanes to automate testing, but the performance was so good that the only way they could test the forward error correction (FEC) was to introduce distortion to the signal path.

Applications from automotive to industrial automation are crying out to be able to benefit from the power of the highest-performance AI chips. These devices, however, can only perform if they are fed from very high-speed interfaces, and those interfaces can no longer be tested using conventional components such as EMRs.

Menlo Micro and its Ideal Switch have changed all that. The advances they deliver in linearity, reliability, and miniaturisation are keeping down the cost of producing AI chips, opening vast new opportunities for AI-driven devices in industry sectors large and small.

All you have to do is switch.

By Menlo Micro

This article originally appeared in the July’25 magazine issue of Electronic Specifier Design – see ES’s Magazine Archives for more featured publications.