The use of agricultural drones is one of the ways they are doing this to care for and protect their crops.

Unmanned aerial vehicles used in AI operations (more commonly known as drones) are the newest trend of smart farming to collect data that farmers can use to support their work.

There are several types of drones on the market that are used for different commercial and industrial applications. Drones that survey and spray for precision agriculture, search, and rescue operations, take aerial photography, map infrastructure, utilities inspections such as roads, power lines, pipelines and railways, and drones that deliver goods.

As drones are used more, the components that are part of them need to ensure a high level of reliability, safety, durability, and robustness.

This turned out to be a challenge for an Indian manufacturer of commercial robotic drones and drone-based solutions who was struggling to find a qualified high-power connector for the power supply module of a new UAV to be used for precision spraying of pesticides for agriculture and livestock. The customer normally produces drones for crop protection, crop health, precision farming and yield monitoring using artificial intelligence.

In this specific case the drones’ final use is to spray onto fields a range of agrochemical, fertilisers, and speciality nutrients. The drones can operate in multiple modes and can collide into crops and plants while in operation so all parts must be rugged to ensure reliable performance and prevention of any failures or malfunction.

The connectivity solution Smiths Interconnect was asked to provide was the main connector which connects the drone with its battery for power supply and the required performance needed to allow at least 25 minutes flight time with coverage of up to six acres per battery charge using artificial intelligence-assisted navigation.

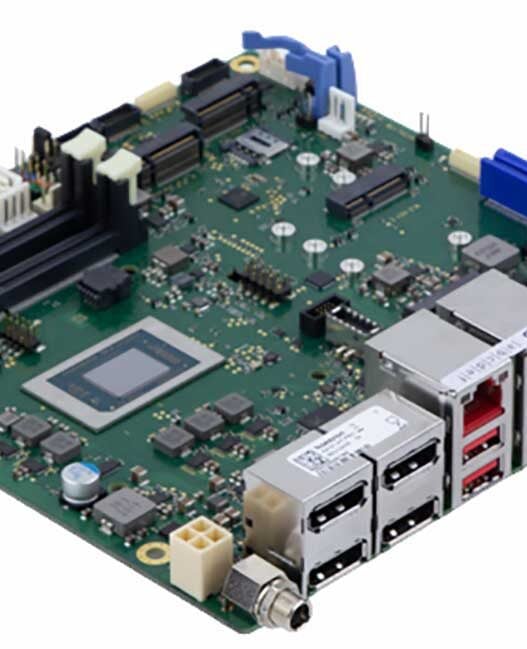

Smiths Interconnect was able to provide the customer with a modular connector with some specific technical characteristics. The choice was a special float mount, rack & panel, UL-qualified modular solution with mixed signal and power contacts.

Based on Smiths Interconnect’s high performance patented Hypertac hyperboloid technology, this compact connector offers a flexible and reliable design and the use of premium material; however, it wasn’t just the contact technology and the rugged materials that secured the contract.

The Smiths Interconnect technical team took a collaborative approach in customising the solution and they had the ability to quickly obtain components to qualify the new drones by the customer’s deadline.

Smiths Interconnect’s products had the speed to provide an interconnect solution for an application that had not been explored, previously, resulting in the development of a dependable and satisfactory connector for the new drone battery pack.

Additionally, the customer gained an important competitive advantage through a reliable and durable interconnect solution that can guarantee stability and maximum power charge throughout the spraying duration.