At this event, Ventec is set to introduce its pro-bond and thermal-bond bond ply dielectrics, designed specifically for high-speed signal integrity with minimal losses and effective thermal management in ML PCB stack-ups. These advancements are crucial for the latest computing and networking applications, including high layer count multilayers, high-performance motherboards, server backplanes, and cellular network power amplifiers.

The initial product lineup features Resin Coated Copper (RCC) and Resin Coated Film (RCF) bond ply b-stage dielectric materials. The RCC bond ply, a non-reinforced adhesive system applied to ultra-thin copper foil, ranging from 1.5-5.0μm and supported on an 18μm carrier foil, is ideal for high-performance and reliable multilayer PCB stack-ups.

Similarly, the RCF bond ply, also a non-reinforced adhesive system, is coated onto PET film for high-performance and reliable multilayer PCB stack-ups. Ventec is introducing four pro-bond formulas that provide an exceptional mix of low dissipation factor (Df) with a range of dielectric constants (Dk) to optimise the design window for critical PCB parameters.

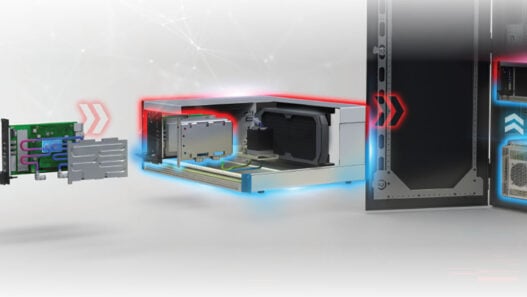

Moreover, Ventec’s new thermal-bond portfolio substantially enhances the thermal conductivity achievable with non-IMS substrates. The thermal-bond 5.0F, offering a thermal conductivity of 7.0 W/m.K, and thermal-bond 3.0F, with 3.6 W/m.K, are perfectly suited for high-power circuits. Notable applications for thermal-bond materials include LED lighting boards, network-powered and battery-powered DC/DC converters, distributed energy harvesting systems, Cloud AI accelerators, and high-power motor drives and controllers.

Following the launch of Ventec Giga Solutions in 2023, Ventec’s service offering now encompasses a comprehensive one-stop solution for PCB manufacturing, ranging from the development of high-performance substrate materials to the supply of capital equipment, factory planning, setup, and process support. A recent partnership with Cardel Group expands Ventec’s reach into the USA, including a refurbishment service for separator plates used in PCB lamination.

Mark Goodwin, Ventec’s COO for EMEA & Americas, emphasised the company’s ongoing commitment to enhancing its offerings: “We continue to strengthen and extend the Ventec value proposition, leveraging our expertise in all areas of PCB fabrication. We are looking forward to welcoming visitors to our booth at APEX this April, to present the breadth of solutions we can now offer to ensure resilient and secure local PCB manufacturing.”

Visitors are invited to booth no. 4309 at the IPC APEX Expo, Anaheim Convention Centre, to explore Ventec’s latest innovations in specialty substrate materials, process consumables, and comprehensive fabrication services.