Semiconductor equipment makers ASMPT and Kokusai Electric have entered a joint development agreement aimed at advancing packaging technologies critical to high-performance computing and artificial intelligence.

The partnership will focus on hybrid bonding and thermo-compression bonding — processes seen as essential for 2.5D and 3D heterogeneous integration, a technique that allows chips to be stacked or closely interconnected to deliver greater computing power at lower energy cost.

Kokusai, a Japanese group known for thin-film deposition equipment, will combine its front-end expertise with ASMPT’s precision bonding platforms. The companies said the collaboration is intended to improve product yield, quality, and time-to-market for next-generation semiconductors.

Hidehiro Yanagawa, Executive Vice President of Kokusai Electric, said the initiative sought to “set new industry benchmarks” for both bonding technologies.

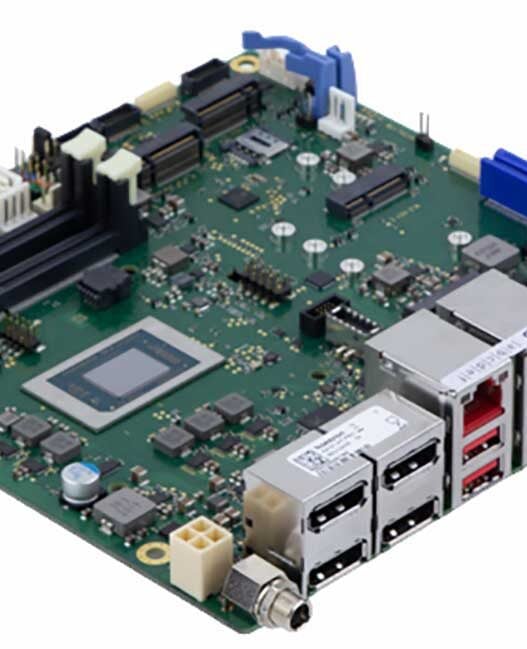

Nelson Fan, Vice President of ASMPT Semi Solutions, described the agreement as an opportunity to “push the boundaries of advanced packaging”, highlighting ASMPT’s proprietary AOR TCB, and LITHOBOLT hybrid bonding systems.

Both companies are positioning themselves for the growing demand in high-performance and energy-efficient chips used in data centres, AI accelerators, and advanced consumer electronics.

ASMPT, headquartered in Singapore and listed in Hong Kong, supplies hardware and software for semiconductor assembly, and packaging as well as surface-mount technology. The company is a constituent of the Hang Seng Composite MidCap Index.

Kokusai Electric, which has been spun out of Hitachi in 2018, and was backed by private equity before relisting, has been expanding its focus on advanced front-end manufacturing tools.

The deal underscores the intensifying competition among equipment suppliers to establish a foothold in advanced packaging, seen by many in the industry as the next bottleneck — and opportunity — in semiconductor scaling.