A pioneer in the development of flexible and high frequency circuit materials for the printed circuit industry, Rogers Corporation will showcase innovative material solutions such as the new R/flex JADE A series flexible circuit materials, R/flex 8080 photoimageable covercoats, RO4000 high frequency laminates with enhanced copper bond technology and LONGLITE adhesiveless flexible circuit materials at their booth at the show.

The recently announced R/flex JADE A series material is a halogen-free, transparent epoxy polyimide laminate system that is safe for the environment and delivers superior performance in an all-inclusive package for flexible circuit designs. An extension of the Rogers R/flex CRYSTAL® flexible materials product line, the new R/flex JADE A epoxy adhesive system is ideal for a wide range of applications including hard disk drives, cellular phones, laptop computers, personal digital assistants and semiconductor packaging applications.

R/flex JADE A series products are RoHS compliant and UL 94 V-0 classified for flame retardant performance. Outstanding thermal stability enables R/flex JADE A laminates to withstand multiple passes through a lead-free soldering process. The materials’ excellent dimensional stability and adjustable squeeze-out control results in increased yields and better results in fine-line, tight tolerance design applications. Like the R/flex CRYSTAL line of products, the R/flex JADE A series features a transparent adhesive system that simplifies optical inspections.

Designed for performance-sensitive, high volume commercial applications, RO4000 high frequency circuit materials with Enhanced Copper Bond Technology offer superior cost-effective performance with reduced PIM. RO4000 materials are woven glass reinforced/ceramic filled thermoset materials with a very high glass transition temperature. Easily fabricated into printed circuit boards using standard FR4 processing techniques, RO4000 enhanced bond technology can be processed by automated handling systems and scrubbing equipment used for copper surface preparation. Additionally, this series is optimized for use in RF identification tags, microstrip and cellular base station antennas, power amplifiers, spread spectrum communications systems as well as direct broadcast satellites.

Rogers LONGLITE adhesiveless flex series double and single-clad laminates are designed to meet manufacturers’ high performance interconnection requirements. Offering excellent dimensional stability for use in making fine line flexible circuit designs and assemblies, these halogen-free laminates provide superior solder resistance compared to competitive products, making them ideal for lead-free soldering temperatures.

Suitable for harsh working environments, LONGLITE adhesiveless flex series offers a broad range of copper foil and dielectric film thicknesses, including the inner copper foils required in high-density circuit patterns. These laminates are designed for use in COF (Chip on Flex), cellular phones, digital still cameras, RFPC, LCD interconnections and medical, defense and aerospace high-reliability FPC (Flexible Printed Circuits) applications.

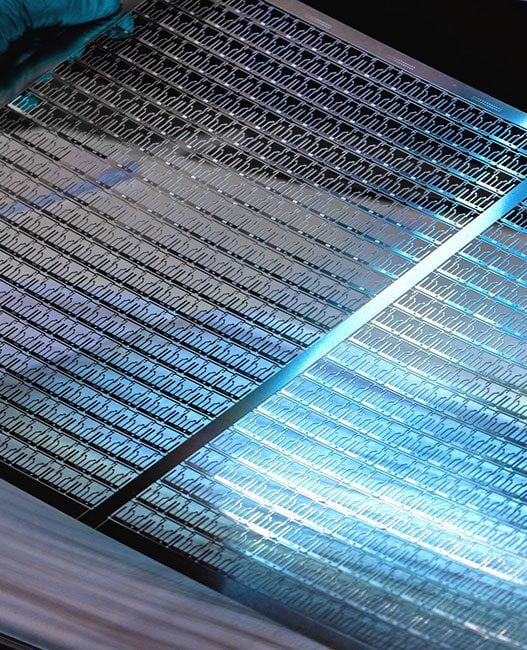

Rogers R/flex 8080 liquid Photoimageable Covercoats provide uniform coverage in mass production applications, enabling printed circuit board manufacturers to achieve ultra-fine, high precision etch patterns that have traditionally been unattainable through conventional screen printing. Providing outstanding imaging resolution, flexibility and creaseability, R/flex 8080 allows for the manufacturing of high precision patterns that are needed for today’s high-density flexible printed circuits. By eliminating the need for coverfilm lamination, punching and drilling processes, this product’s unique design reduces tooling costs and lead times for all five formulation versions available.

R/flex 8080 provides excellent electrical, thermal and chemical properties mandated by IPC Specification SM-840, Rev.C. Contact photo exposed and alkaline developable, the R/flex 8080 series provides excellent resistance to all plating processes. Processing stability, along with long shelf life and pot life make these covercoats dependable solutions to meet industry performance requirements.