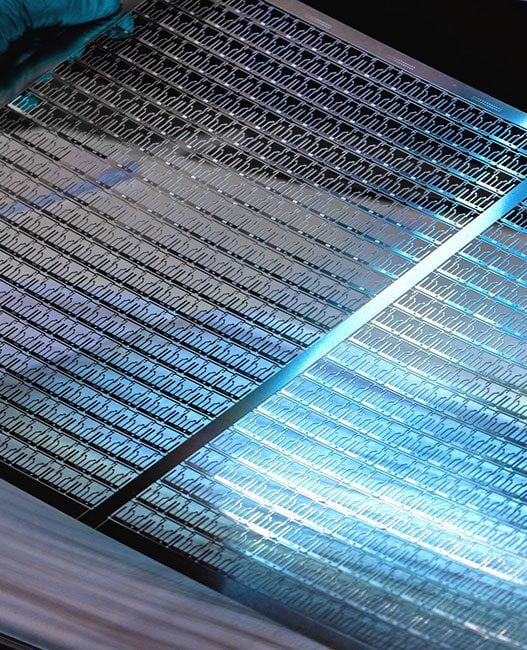

In addition to the design, type-testing and supply of the XLPE subsea cables, Nexans will also supply mechanical and electrical accessories. This includes the onshore transition joints to connect the subsea cables to the land cables, the accessories for the two platforms, comprising hang-off and GIS (gas insulated switchgear) terminations, and four repair joints.

The Northwind wind farm will comprise 72 wind turbines, summing up to a total of 216 MW installed capacity. The power will be delivered to the Belgian electricity network at the ELIA HV connection station in Zeebrugge. The 14 km section of 245 kV cable connecting Belwind Phase 2 to Northwind will consist of three copper cores, each with a cross-section of 400 mm2.

The majority of the 43 km, 245 kV connection from Northwind to Zeebrugge will comprise of three 1000 mm2 copper cores. However, there is a length of the route where the cable has to traverse a sea channel subjected to regular dredging, requiring it to be buried down to 9 metres in the seabed for protection. In order to maintain the electrical performance of the cable along this channel, the copper cross-section will be increased to 1200 mm2 on a 4 km section. This section of cable will have an outer diameter of 265 mm and will weigh 130 kg per meter.

The subsea cables will be manufactured at Nexans’ specialized facility in Halden, Norway. They will also include two FO48 fiber optic elements, manufactured in the Nexans Rognan plant, to enable data communications, control and monitoring for the power transmission system.