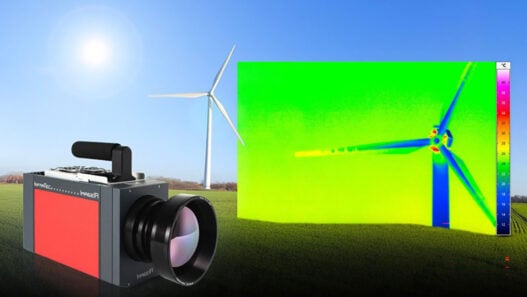

Following Part 1, in this article we continue to delve deeper into the features of the ImageIR 9800, a high-end thermographic camera designed for demanding industrial and research applications.

The ideal choice for industrial and research applications

The ImageIR 9800 combines high spatial and thermal resolution, precise temperature measurement, flexible configuration options, modular lens integration, and reliable performance across a wide temperature range. It allows short integration times, even at low radiation intensities, e.g., low surface temperatures.

Heisig stated: “The high frame rates can be extended when capturing data using the sub-window function. These freely definable sections can be set up quickly and conveniently by click-and-drag. Sub-window image frequencies of up to 5,800Hz can thus be achieved.”

The ImageIR 9800 is equipped with a modern trigger interface for precise signal control and synchronised data acquisition. Thanks to the 10 GigE interface the large amount of data, generated by the high-resolution detector and high frame rates, can be transferred quickly, reliably, and without loss. The integrated multispectral feature allows the fault-free and continuous measurement of temperatures between (-40 … 3,000°C.)

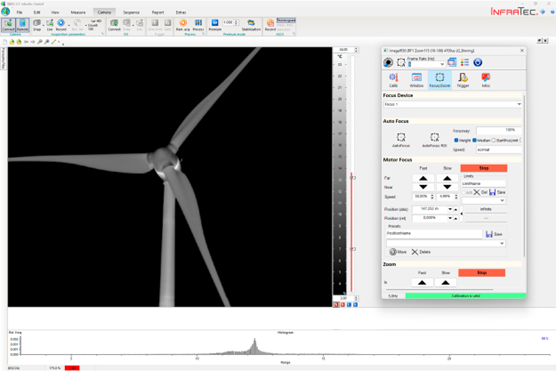

Implications of the integrated linear motor focus

The integrated linear motor focus enables precise, fast, and automated focusing. It can be easily controlled by IRBIS online software.

“The motor focus simplifies handling and ensures optimal measurement results even in challenging scenarios. It is also useful, when working distances change often, supporting efficient measuring and the recording of the best possible data,” Heisig said.

The motor focus is available as a camera-internal function for the use of wide-angle, standard and smaller telephoto lenses. For bigger lenses a motorised microscopic tripod or an external motor focus unit deliver alternatives.

Use examples

For cameras operating at close range, a particularly fine focus setting in conjunction with a comparatively shallow depth of field for macroscopic or microscopic images can help to find the exact focus.

The focusing speed in terms of a rapid measuring sequence can be important for a moving scene or the thermography of complexly shaped components.

Heisig added: “If a scene exhibits such an extremely low thermal contrast that the implemented autofocus algorithms cannot focus reliably enough, you can directly enter a previously measured object distance.”

Implementing configurations to specific needs

The modular design of the ImageIR 9800 allows tailored configurations based on lens and spectral filter selection, optional features such as motorised focus, customised software modules, and adapted measurement ranges.

“The thermal camera also features Multi Integration Time (MIT) and High Sense function. MIT enables the acquisition of multiple thermograms with different calibrations thereby extending the temperature measurement range,” Heisig explained.

For their part, High Sense enhances the existing factory calibration of the thermographic camera. It enables the possibility of setting up individual customised temperature measurement ranges in two different ways: either by selecting a desired integration time or by defining an upper and lower limit of the temperature measurement range.

Data acquisition and processing interface

The thermal camera uses a 10 GigE interface that enables direct storage and processing of high-resolution full-frame images at up to 180Hz. For internal processing InfraTec offers an integrated Software Development Kit (SDK) enabling automated evaluation of recorded files.

“High-speed real-time data transmission to an external computer is also more efficient with 10 GigE technology: Distances of over several hundred meters can be bridged by using inexpensive and robust fibre optic cables (multimode) instead of expensive and heavy CAMLink cables with limited cable length (maximum approx. 5m) or expensive frame grabbers (only compatible with desktop PCs),” Heisig commented.

The GenICam software interface, in conjunction with the GigE Vision interface, can be used for plug & play integration of the thermal camera into existing systems and into standard-compliant software such as Halcon Machine Vision Software. The camera once automatically detected can be immediately controlled and operated.

Enabling reliable camera control

The camera is equipped with an internal trigger interface that guarantees high-precision, repeatable, and delay-free triggering, enabling the reliable capture of even very fast processes.

Heisig stated: “It features three configurable inputs and two outputs, either digital or analogue, for camera control and the transmission of control signals. For further functionality a breakout box with a 14-bit ADC is available.”

The trigger interface supports the processing of both incoming and outgoing analogue signals. For instance, an external voltage signal can be read directly from the camera, and this information can be embedded into the thermographic image data.

Control and analysis with IRBIS software

IRBIS enables fast and intuitive camera control, and an efficient data acquisition. It provides numerous analysis and visualisation tools such as image display, video export, and various data formats. It contains extensive measurement and correction functions as well as special algorithms, for example for active thermography.

“The IRBIS software can be configured modularly for specific applications. It features customisable user profiles with an individual layout and a macro editor for programming of additional functions or automation of a sequence of functions,” Heisig said.

Regardless of the respective digital interface of the infrared camera – GigE, 10 GigE, or CamLink – with the IRBIS 3 thermography software, all camera functions can be conveniently remotely-controlled from the computer or tablet PC. Digital thermal images are reliably transmitted to the control/evaluation PC or stored internally.

Considerations to keep in mind

The ImageIR 9800 can be equipped with a wide range of interchangeable lenses – from microscopic or telephoto lenses and other optical modules like extender rings tailored to specific measurement tasks. Standard lenses have a focal length of 13, 25, 50, 100 or 200mm.

Heisig said: “Regarding the frame rate, full-frame images can be captured at 180Hz. For higher rates, the subwindowing function is helpful: In half frame 354Hz are possible, in quarter frame 672Hz. The sub-frame mode with individually defined frames allows frame rates up to 5.800Hz, enabling adaptation to very fast processes.”

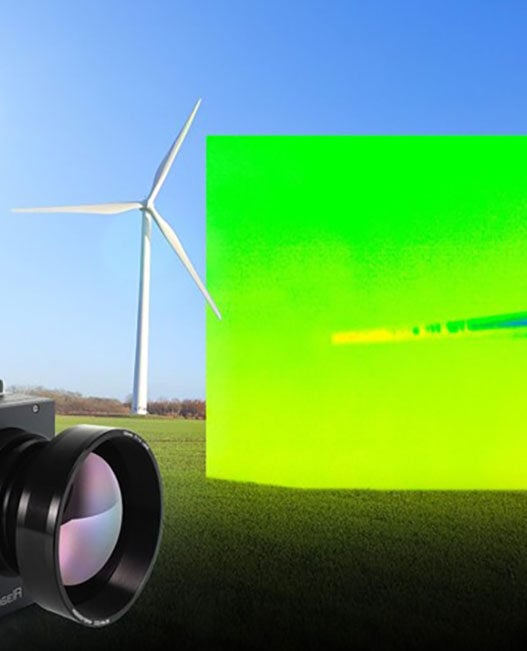

Extremely short integration times and instant capture mode ensure sharp, distortion-free images even at high object speeds and low radiation intensity, enabling accurate temperature measurements of fast-moving objects. This is a very useful feature, for instance, when conducting aerial thermography, where the aircraft or drone flies over the inspected areas to detect minor deviations in environmental temperatures.

To perform the accurate analysis of fast-moving objects, the snapshot mode of ImageIR 9800 is essential. It minimises the time needed to capture an accurate thermogram of the fast-moving object. Of course, the excellent signal-to-noise ratio also supports this.

“The ImageIR 9800 represents a highly flexible, high-performance thermography system combining cutting-edge detector technology, modular design, advanced software, and strong service support, making it suitable for a broad range of industrial and scientific measurement tasks. On the market for LWIR cameras, the ImageIR 9800 with its high frame rate and spatial resolution is outstanding,” Heisig concluded.

About the author:

Diego de Azcuénaga, Contributing Writer