As a cutting-edge, high-resolution thermographic solution, the ImageIR 9800 excels at measuring highly dynamic events across the long-wave infrared spectrum, even at low ambient temperatures.

When integrated with the correct telephoto optics, the new ImageIR cameras enable precise remote temperature monitoring over long ranges. Utilising a cooled focal plane array photon detector, the device achieves pristine images and stable sequences, even with brief exposure periods or minimal incoming radiation.

In an exclusive interview for Electronic Specifier, Konrad Heisig, Director of the Mechanical Design and Development Department in the Infrared Measurement Division at InfraTec, emphasised that with its integrated HDR functionality, the camera seamlessly handles extreme temperature variations and wide gradients spanning from -40 to 3,000°C.

Suitable applications for the new ImageIR 9800

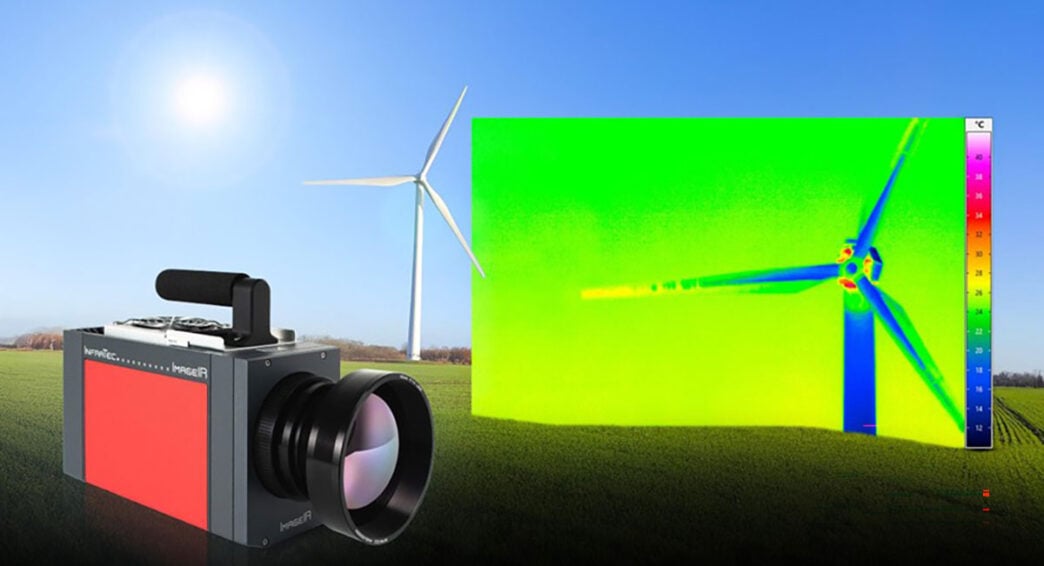

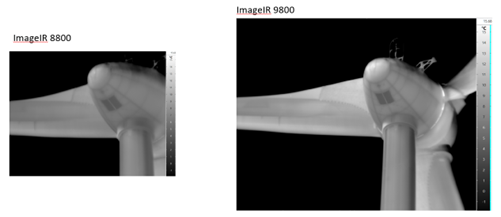

The ImageIR 9800 is suitable for high-resolution thermographic measurements of highly dynamic processes like monitoring wind turbine rotor blades during operation, for long-distance temperature measurement like monitoring combustion gases and exhaust gas flows or detecting thermal signatures of distant objects.

Heisig added: “The camera is also a great tool for various other demanding industrial and research applications like high-speed thermography.”

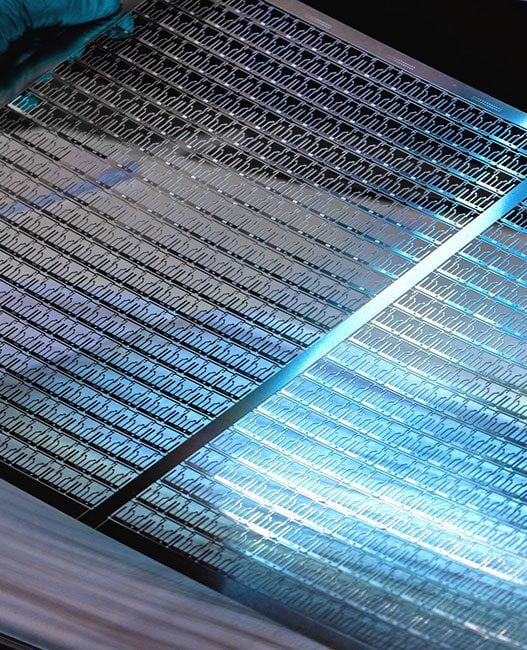

In addition to these specific use cases, the camera’s exceptional speed and sensitivity make it ideal for non-destructive testing (NDT) applications, where rapid thermal changes reveal material defects.

What mechanisms does this infrared camera use?

The ImageIR 9800 can capture full-frame images at frame rates of up to 180Hz and short integration times.

“The snapshot mode (simultaneous exposure of all pixels), a cooled Long-wave Infrared (LWIR) photon detector with (1,280 x 1,024) IR pixels, and various trigger options enable precise, event-controlled data acquisition even during highly dynamic temperature changes,” Heisig explained.

The cooled T2SLS photon detector is optimized for long-wave infrared radiation. It operates in the LWIR spectral range of (7.7…12.5) µm.

Monitoring the operation of the wind turbine rotor blades

Measurement in the LWIR spectral range is key to performing this task. The other is a measurement system carrier that actively tracks the entire system in the form of a co-rotation with the rotor blade. This carrier was developed by Deutsche WindGuard Engineering, InfraTecs partner at the PreciWind project.

“For the first time, the synchronous rotational movement between the rotor blades and the measuring system carrier allows data on surface temperature distribution, deformation and camera images to be recorded and collated during the entire rotor cycle,” Heisig said.

This allows for a better understanding and recording of the influence of wind conditions, sometimes considerably fluctuating, on the rotor blades at different heights.

Measuring the temperature on great distances

The technical requirements for exact measures on great distances are small pixel pitch and the high detector sensitivity of the ImageIR 9800 at low radiation intensities.

Heisig added: “Equipped with appropriate telephoto lenses (200mm) the camera provides a narrow Instantaneous Field of View (iFOV) for detailed measurements.”

This narrow iFOV is particularly crucial in applications such as surveillance, target tracking, and inspecting extensive industrial infrastructure like power lines or large chemical processing plants from a safe vantage point.

Performing long-distance gas monitoring

For reliably monitoring of combustion gases or vehicle exhaust gas flows at long distances the LWIR-sensible detector of the ImageIR 9800 and their high-resolution imaging capabilities have to be combined with multispectral filters.

“These filters allow discriminating gas-specific sub-spectra for a clearer measurement of the crucial signal (like a typical emissivity band) and noise reduction,” Heisig explained.

As a consequence, the specific infrared wavelengths absorbed or emitted by target gases (such as CO2 or various hydrocarbons) are isolated, making plumes visible against the background and significantly enhancing the signal-to-noise ratio.

Offering new functionalities with outstanding features

The High Dynamic Range (HDR) function allows the camera to capture extremely large temperature gradients and variations from (-40 … 3,000°C) without faults. The integrated filter wheel with up to seven positions automatically selects filters appropriate for each temperature range, thus mastering an error-free and uninterrupted measurement of highly dynamic thermal processes.

Heisig added: “At high temperatures high intensities of infrared radiation occur. To attenuate these excessively high intensities, special neutral density filters are placed in front of the camera’s detector.”

This allows measurements to be taken on hot objects up to the upper limit of the temperature measurement range. At the same time, it limits the usable temperature measurement range downwards.

“As can be inferred, to measure temperatures in a very wide temperature measurement range, it is necessary to change the neutral density filters with different, but overlapping, usable temperature measurement ranges,” Heisig commented.

This is usually done in discrete steps and the neutral density filters are changed for each individual measurement range. HDR eliminates the need to interrupt measurements to change filters.

Heisig said: “The function allows continuous recording of measurement scenarios with extremely varying temperatures and thermal analysis of targets that experience extremely rapid temperature changes over a very wide range.”

Providing exceptional image quality

The ImageIR 9800 is characterised by a cooled detector, working in snapshot mode. That means, all pixels are captured at once, not line after line, allowing shorter integration times and higher frame rates.

“Of course, the high spatial and thermal resolution, the excellent signal-to-noise ratio and measurement accuracy (1%) also support image quality,” Heisig underlined.

This simultaneous capture of all pixel data eliminates motion artifacts that are common in scanning-type (rotating shutter) detectors when monitoring fast events, ensuring superior image fidelity for highly dynamic processes.

Heisig added: “Features enabling razor-sharp, distortion-free images include a high-resolution SXGA detector [(1,280 x 1,024 pixels)], a relatively small pitch of only 12µm, an excellent signal-to-noise ratio, a thermal resolution of 30mK, extremely short integration times, and snapshot mode.”

In the second part of this article, we’ll see the outstanding industrial and research applications the ImageIR 9800 camera provides, the Integrated Linear Motor Focus, the Data Acquisition and Processing Interface and the IRBIS Software for camera control.

About the author:

Diego de Azcuénaga, Contributing Writer