The optimum solutions that emerge from such developments make for smooth production processes while cutting total cost of ownership, TCO.

Depending on the individual requirements, we can normally deliver to the customer within the course of a few weeks, but three months is the absolute maximum of time we require, says Andrej Lorkovic, who has been in charge of product management at Belden’s Connectivity Division since the beginning of 2012. As the 42-year-old director of product management explains, Customer-specific developments are a cornerstone of Belden’s growth strategy and Belden’s plans call for this business model to make up 50 percent of the division’s total revenue by 2015. In addition to its core markets of mechanical and plant engineering, Belden also develops products for diverse markets such as enterprise and transportation.

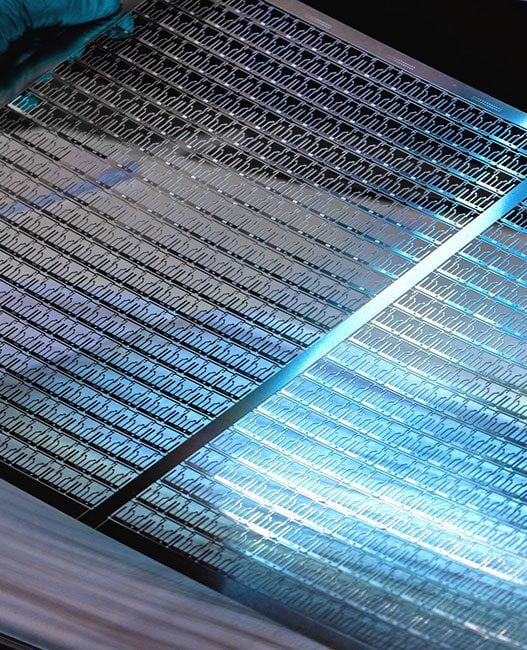

When implementing customized solutions, the Connectivity Division is able to benefit from a comprehensive program of standard products, which is being extended all the time. The extremely robust I/O modules for PROFINET and EtherNet/IP, launched as part of the LioN series at the beginning of this year, are just one example. All our standard products are characterized by robust design and simplicity of use, ensuring optimum reliability, says Lorkovic.

This applies to customer-specific developments as well. In these projects, however, flexibility and response times also play a vital role. We currently implement around 100 projects per month in our Connectivity Center, explains Lorkovic. Simple variants of standard products, such as cables in customized lengths or with individual labeling, are normally delivered within two to four weeks. Offers for this kind of work are sent to customers within two working days. This response speed is possible thanks to almost fully automated underlying processes.

Solutions that deviate from the standard repertoire, however, can take up to several months to complete. A connection cable that we recently developed for configuring M8 sensors had a standard connector at one end and a USB connector at the other, reports Lorkovic. “This example shows how customer-specific developments are able to add real value: a USB interface is more flexible, more reliable and less expensive than the serial interface previously used by the customer.”

Lorkovic says Belden welcomes such opportunities to demonstrate its expertise and capabilities. “The maxim for all our activities is ‘listen, understand, implement and deliver,” he says. We turn our customers’ challenges into a successful collaboration for both parties. We take great satisfaction in supplying our customers with superb solutions that open up completely new opportunities for them – from both the technical and business perspective.

Lumberg Automation, a Belden Brand, means dependable signal transmission – even in harsh industrial environments. In several industrial industries, automation technologies make things move. Since the early 1980s, industrial automation customers have trusted the Lumberg Automation brand to deliver the quality connectors and wiring components necessary for maximum reliability of their dynamic automation technologies. Lumberg Automation products have outstanding compact design, chemical resistance and high mechanical and electrical loading capacity. From single- and double-ended cordsets to centralized or decentralized field bus components, the Lumberg Automation brand offers optimal solutions.